Subscribe Today

Subscribe Today

Subscribe to Woodsmith magazine

Whether you need a little storage or a lot, the modular design of these file cabinets means you can build just what you need (and you can even add additional units later on). Plus, you can customize the look with one of several optional drawer faces.

To build the file cabinet, you need some fairly common hardware. Most of it will be available at home centers and woodworking stores, but there are mail order sources as well.

DRAWER SLIDES. The "big ticket" item is going to be the drawer slides. I chose 22" heavy-duty, over-travel Accuride slides. ("Overtravel" means the drawer opens past the case.) I purchased mine from Rockler (89773), but you can probably special order them through a home center.

However, the "overtravel" feature is optional. Heavy-duty full-extension slides would work fine (and save you a little money). For the desk's pencil drawer, all you need is a pair of 18" full-extension slides (Rockler - 32490).

HARDWARE. The only other items you'll need (besides screws and washers) are threaded inserts and binstyle pulls. The inserts are readily available. The binstyle pulls were ordered from Van Dyke's Restorers (AJ-02012708), but similar pulls are available through other sources.

THREADED INSERT DRIVER. To install the threaded inserts that join the cases, I used a simple driver that chucks into a hand drill. Mine was purchased from Rockler (30174), but McFeely's also has a driver available.

Start by building a pair of two-drawer file cabinets, connect them with a top panel and add a shallow pencil drawer. You'll be surprised at how easy it is to build a handsome desk.

Sort through the terminology and technology of table saw blades. We'll provide all the "tools" you need to make the best choice when buying your next combination blade.

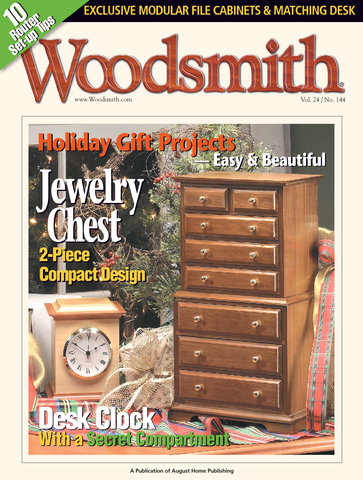

In spite of its small size, there's a lot of woodworking that goes into making this clock. What's more, there's even a secret compartment. It's a great gift project that you can build in a weekend.

There's not much hardware to purchase for the clock on page 20. All you need is a movement and some adhesive-backed felt.

CLOCK MOVEMENT. The movement you'll need is a 31/2"-dia. quartz, "press-in" movement. (Ours has a brass bezel.) This movement should be available at a woodworking store, but if not, there are several sources listed below.

SAW-TOOTH BIT. To create the 3"-dia. opening for the body of the movement, we used a straight bit, a router guide bushing, and a shop-made template. But you can get the job done quicker with a fairly inexpensive Forstner-style bit. Lee Valley currently offers a 3" saw-tooth bit (06J01.48), as in the photo on page 35.

POSTERBOARD & FELT. The only other thing needed for the clock is some posterboard and adhesive-backed felt to line the compartment. Both items may be available at a craft store, but the felt can be purchased from mail order sources.

Whether the router is hand-held or table-mounted, these straightforward techniques and simple jigs will shorten set-up times and improve the accuracy of your cuts.

Even though this elegant jewelry case looks like a full-size chest-on-chest, it's actually sized to sit on top of a dresser. And basic joinery techniques keeps the construction simple.

There's not much hardware needed for the jewelry chest-on-chest.

BRASS KNOBS. The 3/8" x 3/8" brass knobs are available from Lee Valley (00A39.01), but other sources offer small brass knobs as well.

WALNUT PLYWOOD. If you build this chest out of walnut like I did, you'll need 1/4" walnut plywood for the case backs and drawer bottoms. If you aren't able to find any near you, small pieces of walnut plywood can be ordered through the mail order source below. (All the parts can be cut from a 24" x 24" piece.)

FINISH & LINING. To finish the project, we used a can of orange shellac that should be available at local hardware stores. We lined the drawers with posterboard and adhesive-backed felt.