The Best Chop Saw Blades for Precise Cutting

- Best Overall: DEWALT Chop Saw Blade Shop Now ➔

- Most Efficient: Evolution Chop Saw Blade Shop Now ➔

- Most Reliable: Freud Chop Saw Blade Shop Now ➔

- Most Durable: MinCHI257 Chop Saw Blade Shop Now ➔

- Most Accurate: TWIN-TOWN Chop Saw Blade Shop Now ➔

Comparing the Top Chop Saw Blades of 2024

Best Overall

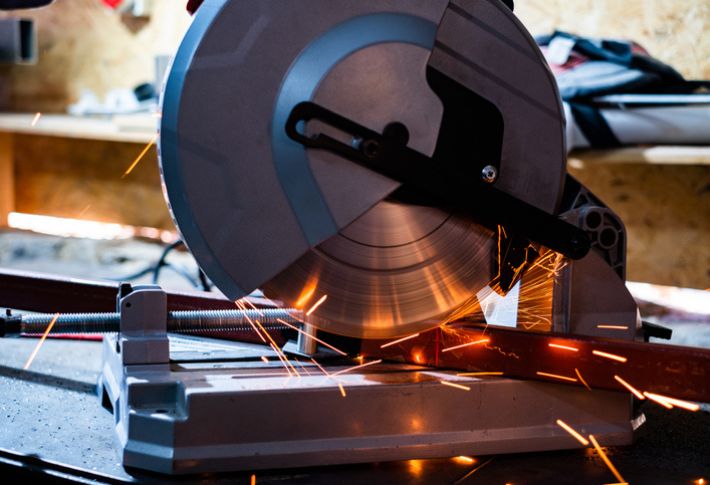

The DEWALT Chop Saw Blade is ideal for anyone working with metal in their projects. This cutting wheel has an exceptional lifespan and can make fast cuts with its high-performance aluminum oxide grain. Additionally, it has a high grain concentration that allows for more aggressive cutting action while ensuring a smoother operation.

This efficient cutting wheel has maximum safety in mind. Its thickness allows for precise cuts with minimum material loss. Its arbor size is compatible with most standard chop saws for easy installation. This chop saw blade is the best on our list to make any job easier and quicker.

Pros

- Smooth cutting with no rough spots

- Easily cuts through square tube mild steel

- Significantly decreases motor strain and heat output

Cons

- Tends to flex

Most Efficient

The Evolution Chop Saw Blade is an amazing tool for any DIYer or professional contractor looking to make quick, accurate cuts. You can cut through various materials, including wood, steel, aluminum, and plastic. Whether you’re cutting boards for a deck build or making precision cuts in plastic and aluminum for a model car build, this blade will do the job without complaint. The exceptional design and the ability to cut such a wide range of materials make this blade a must-have for any tool collection.

Additionally, it produces virtually no heat, burrs, or sparks while making a clean cut. It makes it great for cutting thin and thick materials without any expected hassles, such as burning the material or clogging up the saw blade. It also doesn’t require coolant, facilitating you to make your cuts with precision and confidence.

Pros

- Blade geometry protects carbide teeth from chipping

- Works great on low RPM chop saws

- Cuts through steel effortlessly

Cons

- Some find it difficult to install

Most Reliable

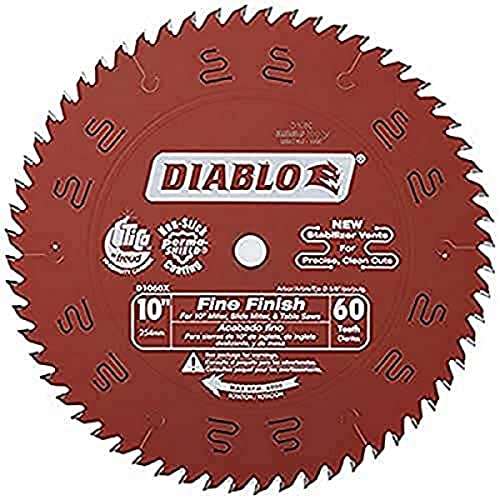

The Freud Chop Saw Blade is a must-have tool for any looking for a reliable saw blade that will help you make accurate, efficient cuts every time. With its top-of-the-line features, this saw blade will help you make fast, durable, and clean cuts on all types of wood. Incorporating Tico Hi-Density carbide in this blade, specifically tailored to each application, improves performance and helps prevent overheating.

The perma-shield non-stick coating protects the blade from heat, gumming, and corrosion for a long-lasting product. This saw blade allows for greater cut accuracy and efficiency with the super-thin laser cut kerf. And, with high-quality materials used in its construction, you can rest assured that this saw blade is reliable and long-lasting.

Pros

- Produces clean, crisp cuts

- Perfectly cut through hardwoods

- High-quality construction makes it long-lasting

Cons

- The blade wobbles

Most Durable

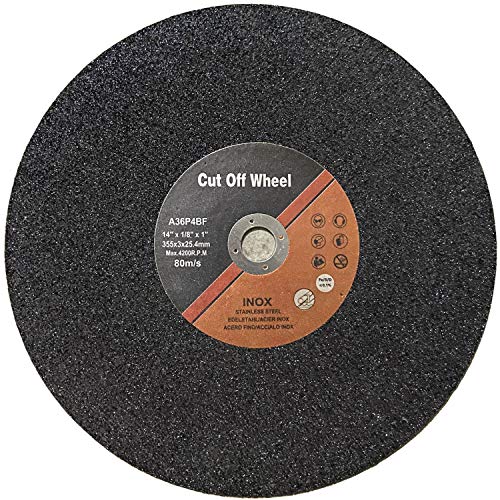

The MinCHI257 Chop Saw Blade is an excellent choice for cutting various metals with precision. This cut-off wheel has a diameter of 14 inches and a thickness of 1/8 inch with a 1-inch arbor. Its aluminum oxide grain provides excellent performance and long-lasting life. It makes it perfect for stationary chop saws and can easily cut through ferrous metals, brass, bronze, carbon steel, and other metals.

Additionally, it’s designed with high precision and accuracy, ensuring you get the most precise cuts possible. It also features a highly durable construction that can withstand heavy use without any issues. In addition, you can use it with both wet and dry applications. It offers high performance, long life, fast cutting, and precision and accuracy for the most precise cuts possible. Additionally, the durable construction ensures you can rely on it for countless projects.

Pros

- Long-lasting and durable construction

- Works well on chop saws

- It cuts thick pipe nicely

Cons

- It wobbles a little

Most Accurate

The TWIN-TOWN Chop Saw Blade is an impressive blend of quality and style. Its elegant design is perfect for industry-level performance, allowing you to easily change abrasive wheels with smoother finishing and a safer touch.

Its newest generation of cermet is a composite material composed of ceramic and metal materials, making it perfect for cutting ensure metals. It provides both a cool cut and an extended lifetime. It can be used on low-rpm metal cutting saws between 1300 to 1500 RPM. This metal cutting saw blade features an anti-kickback design that prevents it from feeding too quickly and ensures safety and accuracy. It helps stabilize the cutting condition and produces a fine finish. It is undoubtedly the tool if you are looking for a metal cutting saw blade with an authentic industry quality-level design.

Pros

- Cuts steel and metal with ease

- Leaves no rough edges or burrs

- Cuts up to 3-inch round and square tube

Cons

- Blades can be dull after a few cuts

Buying Guide: Chop Saw Blades

A chop saw blade may seem like a small and insignificant tool, but it’s a game-changer for any woodworking enthusiast, carpenter, or construction worker. It streamlines your cutting process and elevates your woodworking projects to new levels of precision and accuracy. So, investing in the right chop saw blade can save you time, money, and headaches in the long run while significantly improving your cuts’ efficiency and quality. But with numerous options flooding the market, deciding which one to choose can take time. That’s where our buying guide comes in — we’ll help you navigate the sea of chop saw blades to find the one that fits your needs and budget so you can purchase confidently.

How To Pick the Right Chop Saw Blade

Blade material

The blade material is the most important factor in determining its strength and durability and the level of precision it can achieve. The two main types of blade materials are steel and carbide. Steel blades are generally less expensive but have less edge retention than carbon blades. They are also for softer materials such as wood, fiberglass, and plastic. Carbide blades are more expensive but have greater edge retention, making them better for harder materials such as ceramic tile and masonry.

Arbor size

The arbor size is the diameter of the center hole in the blade and should match your saw’s arbor size for proper fit and performance. If the blade’s arbor size differs from your saw’s, it could damage the blade or motor and create an unsafe operation.

Tooth count

The tooth count of a blade determines how smooth the cut will be but also affects the cutting speeds. Blades with lower tooth counts provide faster cuts, while higher tooth counts create smoother edges but require more power from the saw motor to cut through thicker material.

Blade thickness

The blade’s thickness affects the cut’s depth and how much material it can remove in a single pass. Thicker blades require more power from the saw motor but have superior strength and durability compared to thinner blades. It’s important to consider what type of material you’ll be cutting when selecting a blade thickness; thicker blades handle harder materials but may struggle more with softer materials such as wood or plastic.

Kerf width

The kerf width is how wide a groove the blade creates when cutting with the blade; wider widths make rougher edges but require more power from the saw motor to cut through thicker material. When selecting a blade that fits your needs, balance kerf width and power consumption. Wider kerfs can handle tougher materials but require more power, while narrower kerfs reduce power consumption but may not provide a quality cut on heavier materials.

Hardness

Blade hardness is another factor that affects the longevity of use; harder materials retain their edge longer, while you can sharpen softer materials more easily but wear out more quickly. Before purchasing the chop saw blade, always consider what you’ll be cutting most frequently; softer materials such as wood require harder blades for longer-lasting performance, but harder materials like masonry need softer blades for easier sharpening when needed.

Application type

The application type is what you intend to use the blade for; different materials require different types and performance parameters from a chop saw blade, so make sure you get one that suits your needs specifically. Woodworking blades are designed for cutting through wood material and will have fewer teeth and a thinner profile than industrial blades used on tougher materials like metal or masonry.

Original equipment manufacturer (OEM) compatibility

If you’re replacing an existing blade with a new one, ensure it’s compatible with your saw model and manufacturer’s specifications. It ensures it fits and operates correctly without any safety risks from incorrect setup or using an incompatible part or blade combination.

People Also Asked

Can I use a wood blade on a chop saw to cut metal?

No, using a wood blade on a chop saw to cut metal can be dangerous and may damage the blade. Metal cutting blades withstand the high temperatures and pressures of cutting metal, while wood blades do not. Using the wrong blade can also result in poor-quality cuts or blade breakage.

How often should I change my chop saw blade?

The frequency of blade changes depends on the type of material you're cutting and how often you use the saw. Generally, you should replace the blade when it becomes dull, damaged, or worn. Signs of a dull blade include burning, smoking, and jagged cuts. It's also important to follow the manufacturer's recommendations for blade replacement.

Can I sharpen my chop saw blade?

Don’t sharpen chop saw blades because they are disposable. Attempting to sharpen a blade can be dangerous and may result in poor-quality cuts or breakage. Instead, replace the blade when it becomes dull or damaged.

How long does a chop saw blade last?

The lifespan of a chop saw blade depends on several factors, including the type of material you are cutting, the frequency of use, and the quality of the blade. Generally, a high-quality blade can last several months or even years.

Can I change the chop saw blade on my own?

Yes, you can change the chop saw blade on your own; first, unplug the saw and remove the blade guard. Then, use the arbor lock to hold the blade in place while you loosen the nut or bolt that secures the blade. Remove the old blade and replace it with the new one, making sure to align the blade with the arbor and tighten the nut or bolt securely. Finally, replace the blade guard and test the saw before use.

Article Contributors

The Woodsmith Review Team’s product reviews and in-depth guides are here to help you choose the best tools and gear to build great-looking projects confidently. Woodsmith is reader-supported: When you buy through links on our site, we may earn an affiliate commission. Large language models (like Artificial Intelligence) may have been used in the research and creation of the content.

Inquiries regarding specific articles or product testing should be sent to aimperiapt@gmail.com