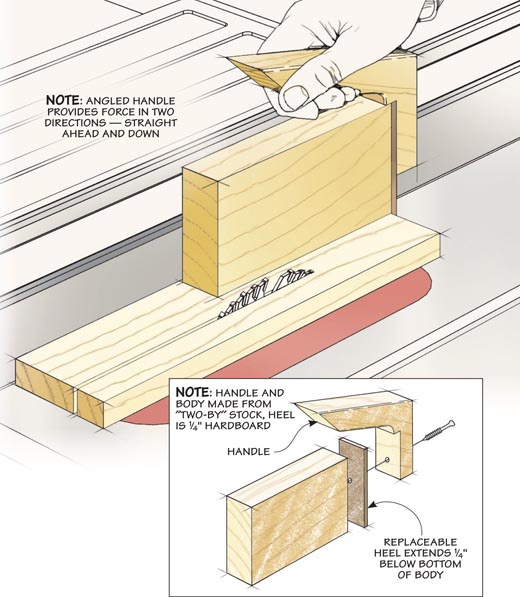

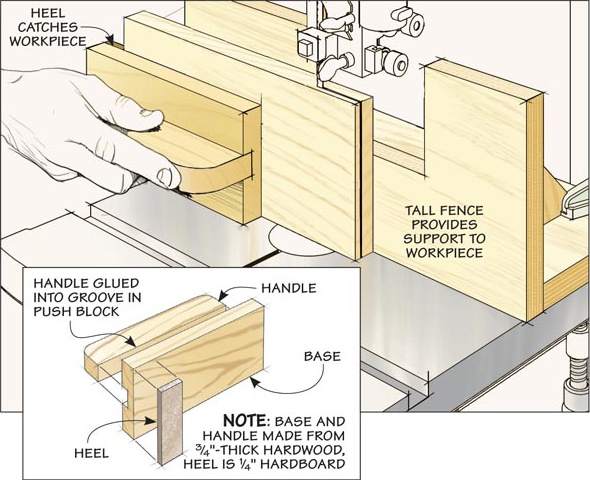

It’s probably the most important safety rule: Keep your fingers away from blades and bits. And push blocks can help out with all tools, starting with the table saw. The best thing about the table saw push block shown here, is the handle. It’s designed to exert forward and downward pressure to push the workpiece through the blade and prevent chattering. The replaceable body (made from “two-by” stock) rides on edge to put extra inches of solid wood between your fingers and the blade. And the hardboard heel, also replaceable, pushes the workpiece past the blade without any danger of kickback. Take the time to make several extra bodies and heels - This way, you’ll always have replacements on hand whenever you need them. You can download the free, step-by-step plans to make this push block at WoodsmithPlans.com.

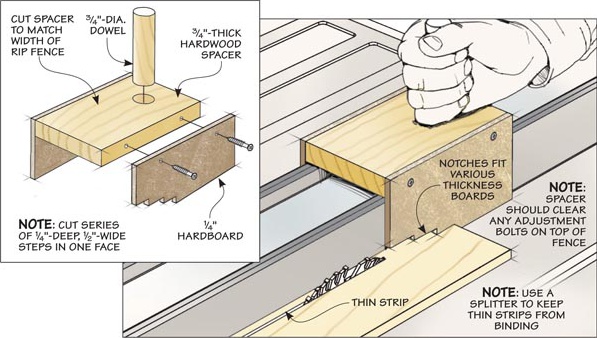

A saddle-style push block will allow you to rip thin pieces safely and consistently at the table saw. This design straddles the rip fence and is made from a couple of pieces of hardboard and a hardwood spacer. (Note: Size the spacer to match the width of the rip fence.) One side of the block has a series of notches that “catch” the end of the workpiece. To use it, simply set the rip fence to the width of the piece you want to cut and rip as many strips as you need from a wide board.

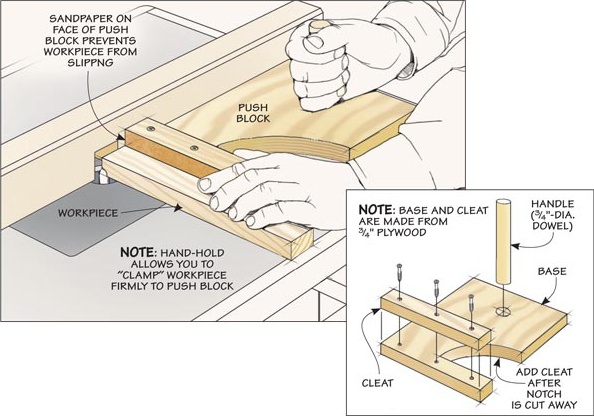

Routing the end grain of a workpiece is always a challenge. To do it easily and safely, you need something to back up the workpiece and keep it square to the bit. You also want to keep your hands safely away from the router bit. This push block does both jobs. It features a base with a cleat at the front. A dowel serves as a simple handle. And, as you can see a cut-out section of the base allows you to securely “clamp” the workpiece to the cleat with your hand.

If you do a lot of resawing, you know there can be problems when you try to push a tall, narrow workpiece through a band saw blade. It helps to have a tall fence for the workpiece to rest against. But more importantly, you need a push block. The thin heel on the back of this push block helps you drive the board through the blade as you come to the end of a cut.

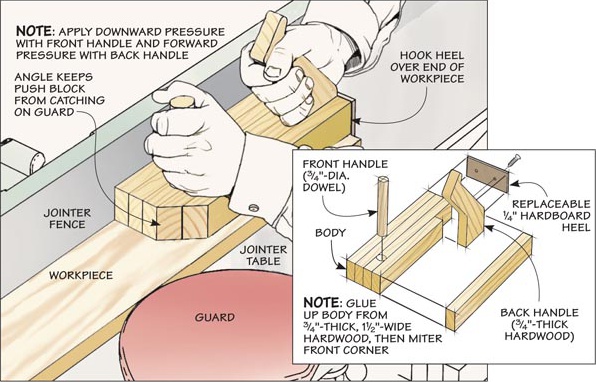

One other tool where I definitely use a push block is a jointer. And this push block offers a two-handed solution to controlling a board as you work. This push block lets you apply forward and downward pressure on a board as you run it through a jointer. The secret is in the handles. The shape and placement of the front and rear handles make it easy to use on both short and long boards. And best of all, the thickness of the body offers ample protection, keeping your hands safely away from the jointer cutterhead.