Selecting the right angle for a dovetail joint is an important concern. But when it comes to choosing router bits, chances are your jig will make that decision for you. The reason for this is the angle of the tails, which are cut by the dovetail bit, must match the template used to cut the pins for a perfect-fitting joint.

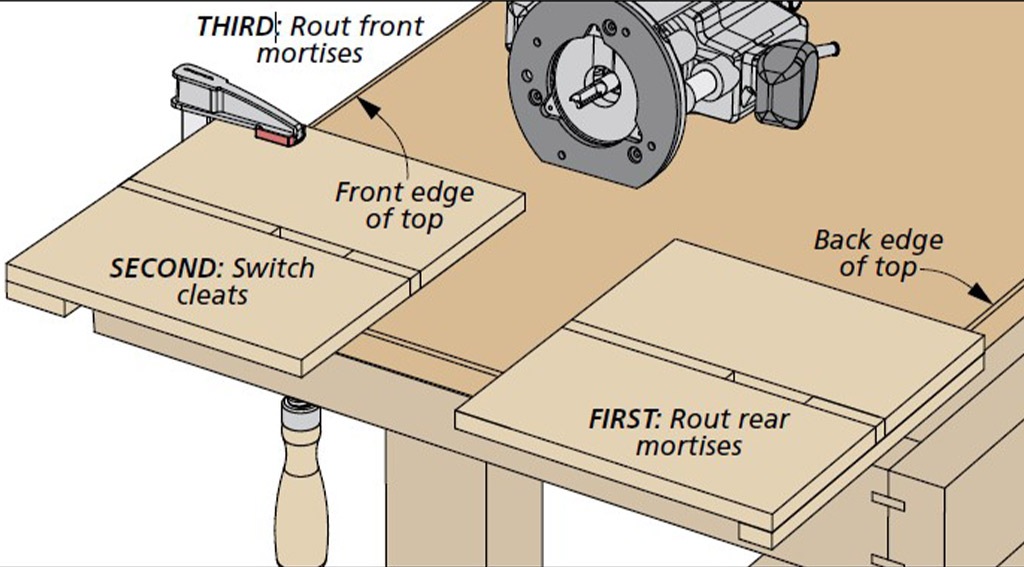

Traditionally, hand-cut dovetails were laid out using a ratio that defined a slope angle. That’s because precision measuring tools weren’t commonly available, but craftsmen could easily measure a slope to define the angles. The drawing shows how it works.

Things changed when dovetail jigs first arrived on the scene. The first dovetail jigs were limited to evenly spaced, half-blind dovetails with equally sized pins and tails. Many of these early jigs were designed to work with a 14° bit. This steeper angle certainly makes for a strong joint. But it also brands the joint as machine cut. As dovetail jigs became more sophisticated, companies like Leigh worked to create a way to vary the spacing of the pins and tails. But even with this innovation in dovetail jigs, the assembled dovetails still displayed the machine-cut look, just spaced differently. To give a more “handcut” look to the finished joint, at least one dovetail jig (WoodRat) uses bits that more closely match the slope of handcut dovetails. Which is why you may find bits designated by slope ratio as well as angles.