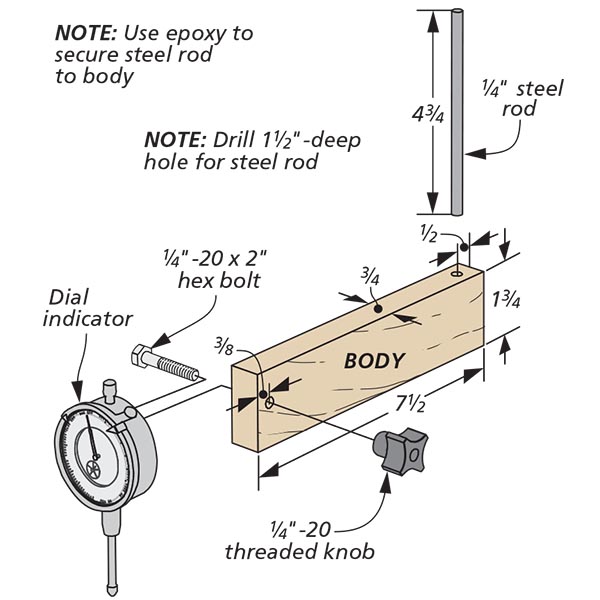

After building a new auxiliary table for my drill press, I wanted to ensure that the table was exactly perpendicular to the drill press spindle. Since I already owned a dial indicator, I came up with this simple jig. This jig allows me to adjust my drill press table to a very precise tolerance. To use the jig, insert the steel rod into the drill chuck and tighten it in place. Adjust the table height so that the indicator needle touches the table surface. Check the reading on the dial at two positions that are 180° from each other. The table can then be adjusted until the readings are the same. Be sure to check several locations front-to-back and side-to-side to ensure accurate adjustments.

After building a new auxiliary table for my drill press, I wanted to ensure that the table was exactly perpendicular to the drill press spindle. Since I already owned a dial indicator, I came up with this simple jig. This jig allows me to adjust my drill press table to a very precise tolerance. To use the jig, insert the steel rod into the drill chuck and tighten it in place. Adjust the table height so that the indicator needle touches the table surface. Check the reading on the dial at two positions that are 180° from each other. The table can then be adjusted until the readings are the same. Be sure to check several locations front-to-back and side-to-side to ensure accurate adjustments.

Special Offer