My shop is small, so mobile bases for my tools are a must. The problem with most commercial bases is that the casters are outside of the tool stand and it’s easy to trip over them. The compact, shop-made version you see here places the casters on the inside of the stand. And what’s more, the design is easy to operate with light foot pressure. Plus, it uses common, inexpensive hardware.

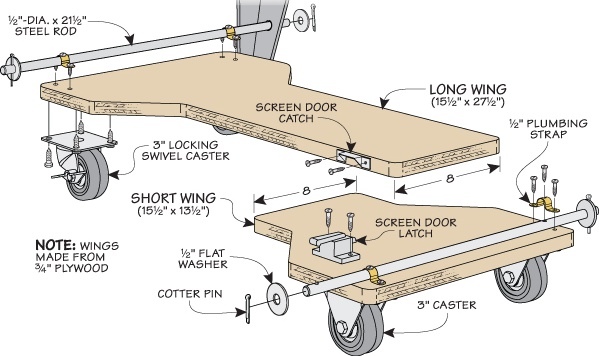

The two overlapping, T-shaped “wings” hinge on 1/2”-dia. steel rods. The wings are sized to fit inside the legs of the stand. When the wings are in the flat, or “down” position, the legs of the tool stand should be lifted off the floor about 1/8".

To locate and drill the holes in the legs of the stand, you’ll need to install the casters on the wings and temporarily clamp the wings together. To take into account the 1/4” radius of the steel rod plus the 1/8” the stand will be lifted off of the floor, I placed 3/8”-thick spacers under the legs of the stand.

All you do is slide the wing assembly under the stand and mark the legs using the top of the wings as a reference for the hole centers. Then, cut and drill the steel rods and install them, securing them with washers and cotter pins.

With the rods in place, you can attach each wing to the rod with a pair of straps. I drilled and installed a screw through the rod to keep the wings from slipping side-to-side. Finally, I installed a screen door latch to secure the wings in the “mobile” position when moving the tool. Simply tapping the latch with your toe releases the wings to lower the stand to the floor.