In this episode of CNC Basecamp I demonstrate an easy method to create intricate and interesting panels for cabinet doors, folding screens, box lids and more beginning with a simple shape and expanding it through repetition into a complex pattern.

To demonstrate this design method, I'm building a decorative garden trellis using a unique pattern created for the panels. Most houses have some blank spots on the back or sides that cry for some decoration, so a wall mounted garden trellis can be a perfect addition for those spots bringing interest and beauty.

The first step in creating the trellis is to lay out the overall form. I prefer to create a series of panels. Multiple panels allow us to fill a large space without having to make one enormous trellis, simplifying construction, installation and adding visual interest. The overall form can be a series of panels arranged side by side, a series of panels arranged vertically and combinations of different shapes and architectural elements.

The demonstration trellis is a combination of a small solid panel below with a v-carved garden saying, a large panel above that will feature our design work, and all topped with an arched panel also featuring our panel design.

The panel design process begins with a simple flower. You can use any shape, but it needs to be easily identifiable and not overly complex. Visually busy shapes are hard to discern in large panels. The flower shape I chose was sketched on paper, scanned and traced using the drawing tools in my design program and saved as a DXF file. If you are not artistically inclined do a search on the internet for “drawings of……” to find images of your theme as a starting point.

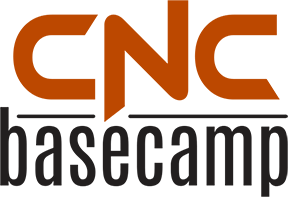

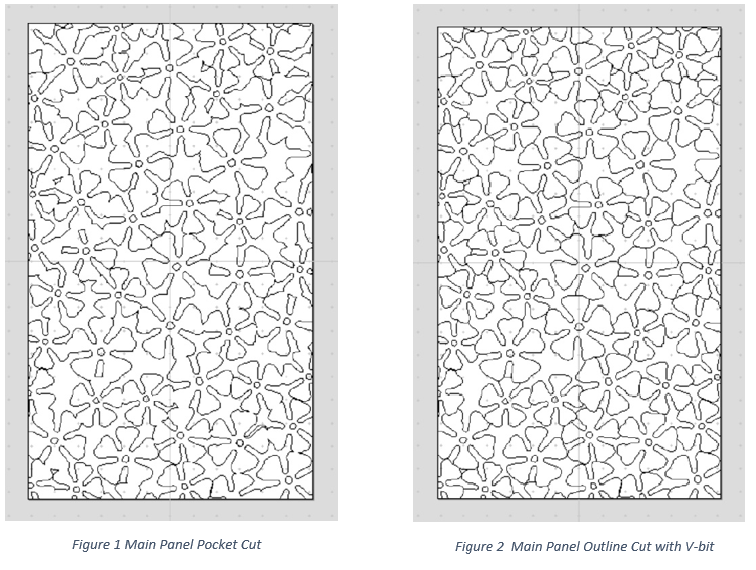

With the base image established it is time to start laying out the pattern. I use Vectric VCarve and began by entering the material size of the panel needed for the trellis. Next, I imported the flower shape and using the size and rotate tools created a group of flowers of different sizes and orientations. One flower at a time, the design was built by dragging and positioning each flower to overlap the edges of the material and each other. When using this method, it should look random, without “sub-patterns” forming.

Once the flowers covered the panel/material interior and boundary, I saved the file and copied it. One of the files was set up to trace the flower outlines with a v-bit. Tracing the shapes is important so that they are easily seen as flowers. This file was prepared by deleting the overlapping lines of the flowers. In the other file I deleted lines to leave only the areas that would be pierced by the router in a series of pocket cuts.

Variations that can make a difference are to cut some areas below the surface of the panel or to add a layer on top that reinforce the primary shape. This will allow the observer to immediately identify the primary element in the design and they can be quite fun. For this trellis project, I opted to cut a number of flowers from aluminum for contrast, as well.

Simple and direct, designing with repeating shapes, each slightly modified, and creating beautiful patterns is easy. Give it a try with your next project - your CNC machine is waiting!