During construction of a project, more often than not, I make at least one trip to the band saw. Usually this involves cutting a part to shape “free-hand.” By this, I mean simply cutting to a layout line without the aid of a fence or other type of guide. This is essentially what the band saw is designed to do. The task can be as simple as making a straight taper cut or something more involved like shaping a complex profile. The catch is that good results are not automatic. Inaccurate cuts with rough, burned edges can force you to perform a lot of tedious cleanup on the workpiece with a file, sandpaper, or sanding drum. But a poor result usually stems from a hasty setup and execution. All it takes is a little planning and the right approach to get clean, precise cuts.

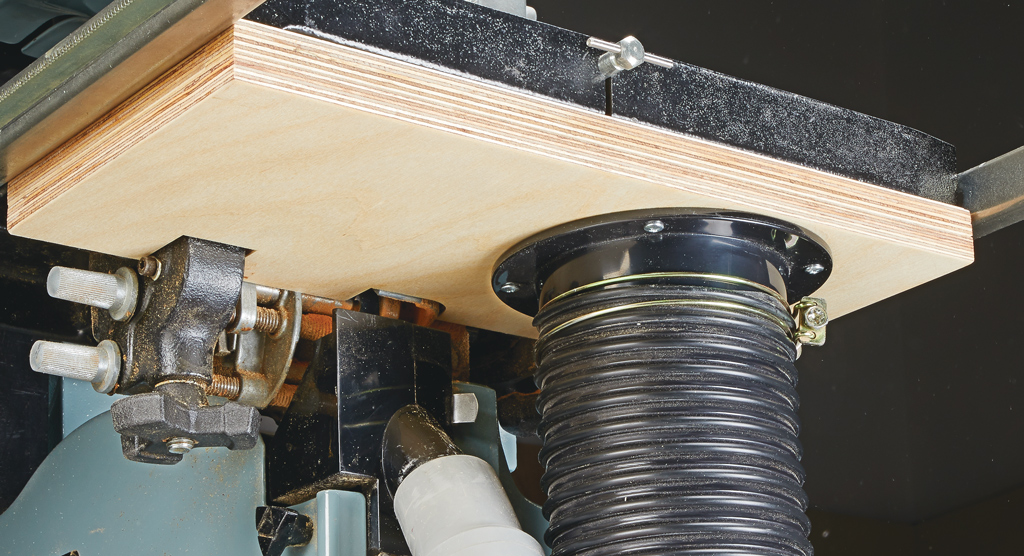

The starting point is proper setup of the saw. And the first step is to choose the right blade for the job. When cutting a profile, you need to match the width of the blade to the contour of the curve. In a nutshell, the narrower the blade, the tighter the radius it will cut. A blade that’s too wide may not allow for the turns necessary to follow a layout line. For general use, a 1⁄4"-wide blade with 6 teeth per inch works well. Setting the height of the blade guides correctly is the second component of the setup. The guides should be as close to the surface of the workpiece as possible without blocking your view of the layout line . This helps minimize blade vibration and deflection.

Once the setup is complete, don’t be in a rush to start the cuts. Sometimes a little planning can actually help get the job done quicker and easier. Let me offer some food for thought. First, when marking a profile on a workpiece, try to keep the layout lines 1⁄8" or more back from any edge. The goal is to prevent the blade from breaking through the edge during the cut. A continuous cut in which the blade is always fully engaged will be much smoother.

Now that you’re ready to start a cut, you have to ask, “how close to the layout line do I want to be?” If the saw is set up properly — the right blade and guide setting — you should be able to cut within about 1⁄32" of the line without fear of crossing over (right drawing below). This will leave you with a minimum of cleanup after the cut is completed. A slow, steady feed rate makes it easier to follow a layout line. To avoid burning and “hiccups” in the cut, always keep the workpiece moving. I like to focus my eyes on the layout line just ahead of the point of the cut. This allows you to anticipate changes in direction and you’ll be able to steer more easily and accurately.