A planer’s strong suit is smoothly surfacing stock down to a desired thickness. And that’s an extremely valuable, time-saving service. And although it’s not necessarily designed to joint an edge or flatten a board, it can do both of these jobs with help from a couple of simple jigs.

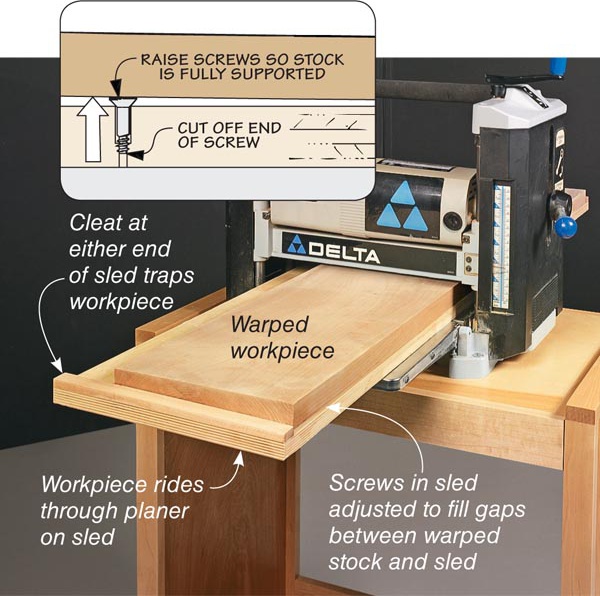

A planer won’t take the end-to-end bow, warp, or twist out of a board. The feed rollers simply force the workpiece flat to the bed as it passes under the cutterhead and you end up with a thinner piece that’s still not straight. The secret to getting perfectly straight boards from your planer is to use the simple sled shown here. The principle is pretty simple. The sled keeps the irregular workpiece from being pushed flat to the bed and allows the planer to create a smooth, flat, and straight face. A series of screws along both sides of the bed of the sled are adjusted to provide support at the “gaps” as the board is planed. And once the upper face is planed straight, the sled is removed to plane the opposite face.

Your planer can also substitute as an effective edge jointer. This jig essentially serves the same purpose as the fence on a jointer — keeping the edge of the workpiece square to the knives as it passes through the planer. It can accommodate a wide range of stock thicknesses and works great for jointing multiple pieces to a consistent width. The jig consists of a plywood bed, a fixed fence attached to the bed, and an adjustable fence that’s clamped in place. To use the jig, you place the workpiece against the fixed fence and then sandwich it snugly with the adjustable fence. The adjustable fence is clamped at both the infeed and outfeed sides of the planer. Then you simply adjust the cutting depth and run the workpiece through the planer.

*You can get the step-by-step plans to build the Folding Worktable (seen in the main photo) from WoodsmithPlans.com.