Correctly installed, butt hinges like these from Horton Brasses are one of those last-minute details that often make a completed project shine. But if the hinges aren’t installed with care, the lid or door won’t fit right or operate properly. It all starts with how you prepare the hinge mortises. A properly fitting hinge mortise is a sign of good craftsmanship.

The good news is, there are several ways to get the job done. It’s all a matter of which technique you’re most comfortable with. Plus, this gives you the opportunity to learn some new techniques and put them to use.

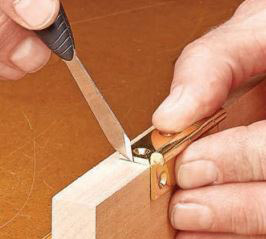

NO MEASURING. The first thing to do is set aside your ruler. For all of the techniques discussed here, the best layout tools are the hinges, a knife, and a marking gauge. I like to wrap the hinge around the edge of the workpiece and score the outline of the leaf with a knife.

It’s best to make several passes, especially across the grain. This helps prevent tearout when removing the waste. It also creates crisp edges for the mortise. It’s also helpful to mark a guideline for the depth of the mortise. My favorite tool for this task is a marking gauge. Use the leaf of the hinge as a guide to set the fence of the marking gauge, then score the workpiece.

With those two tasks done, you can use one of the techniques shown here to create the mortise.

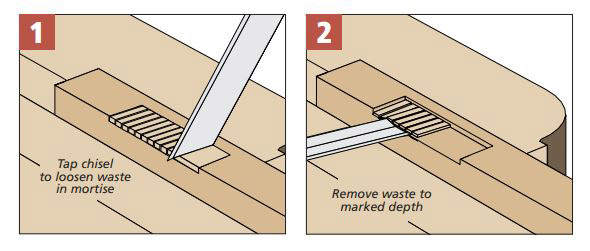

CHISEL

A chisel is one of the simplest tools for creating hinge mortises. The drawings show the quick and easy process I use.

SCORE & PARE. The first step is to make a series of light, cross-grain cuts by using a mallet to tap the chisel. This severs the long grain into shorter segments, making it easier to pare away the waste to the proper depth. Then it’s time to switch to more of a slicing action to remove the chips. Here, it pays to go slow and make several passes, going deeper with each pass. Use the leaf of the hinge to gauge your progess on the depth of cut. The goal is for the leaf to sit flush with the surface. And it’s important to maintain control of the chisel during this step to avoid cutting beyond the mortise.

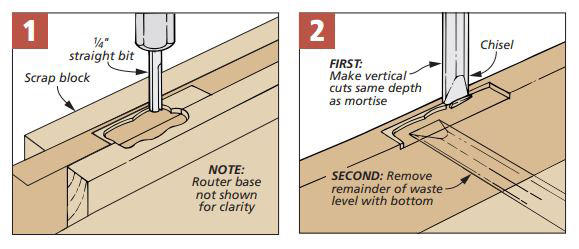

HAND-HELD ROUTER. Another tool that’s great for removing the bulk of the waste is a compact router. After marking the outline of the mortise as before, install a 1 ⁄4" straight bit in the router. Use the hinge leaf as a guide to set the bit depth.

To help support the router on the edge of a workpiece, it’s a good idea to clamp scrap pieces to the sides of the workpiece. You’ll want to keep them flush with the workpiece for routing to a consistent depth.

Then it’s a matter of plunging the router into the waste area of the mortise and carefully working close to your scored lines. A chisel makes easy work of cleaning up the rest of the waste. No matter which technique you decide to use, the results will speak for themselves.