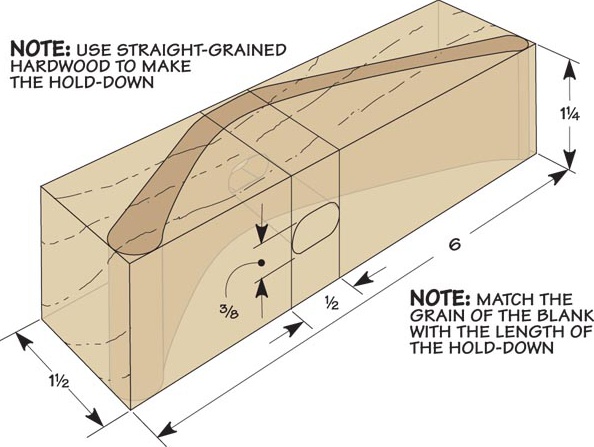

A shop-made hold-down is a great way to keep your work firmly in place. As you can see, one end of the hold-down rests on the tabletop, while the other end presses against the workpiece. The clamping pressure is produced by tightening a knob and washer on the end of a flange bolt, which rides in T-track. To make this clamp, you’ll want to use hardwood stock. (Any type will do.) What’s more important is that you’re careful to align the grain with the length of the clamp. This way, you don’t have to worry about the clamp cracking when you apply pressure from the bolt.

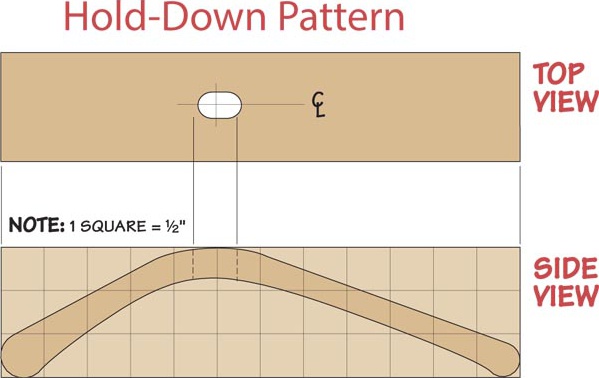

To make the hold-down, transfer the pattern from the drawing below to the side of your blank. You can either enlarge the pattern on a copy machine and attach it to the blank or lay out the pattern by hand using the grid marks.

It’s a good idea to drill the holes for the slot before shaping the hold-down. The slot accepts the flange bolt and is located at the highest point in the curve of the pattern. To make the slot, I drilled a series of holes on the drill press and then cleaned up the slot with a chisel and file. All that’s left to do is cut out the hold-down on the band saw and sand it smooth.