I find myself using corner chamfers on many projects. To help speed up this sometimes lengthy process and get consistent results, I built the jig that’s shown above.

I find myself using corner chamfers on many projects. To help speed up this sometimes lengthy process and get consistent results, I built the jig that’s shown above.

Adjustable.

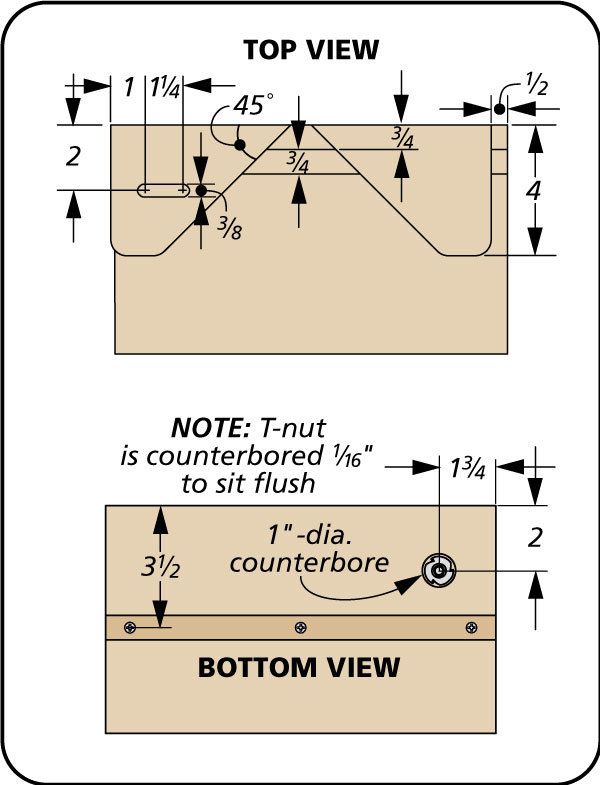

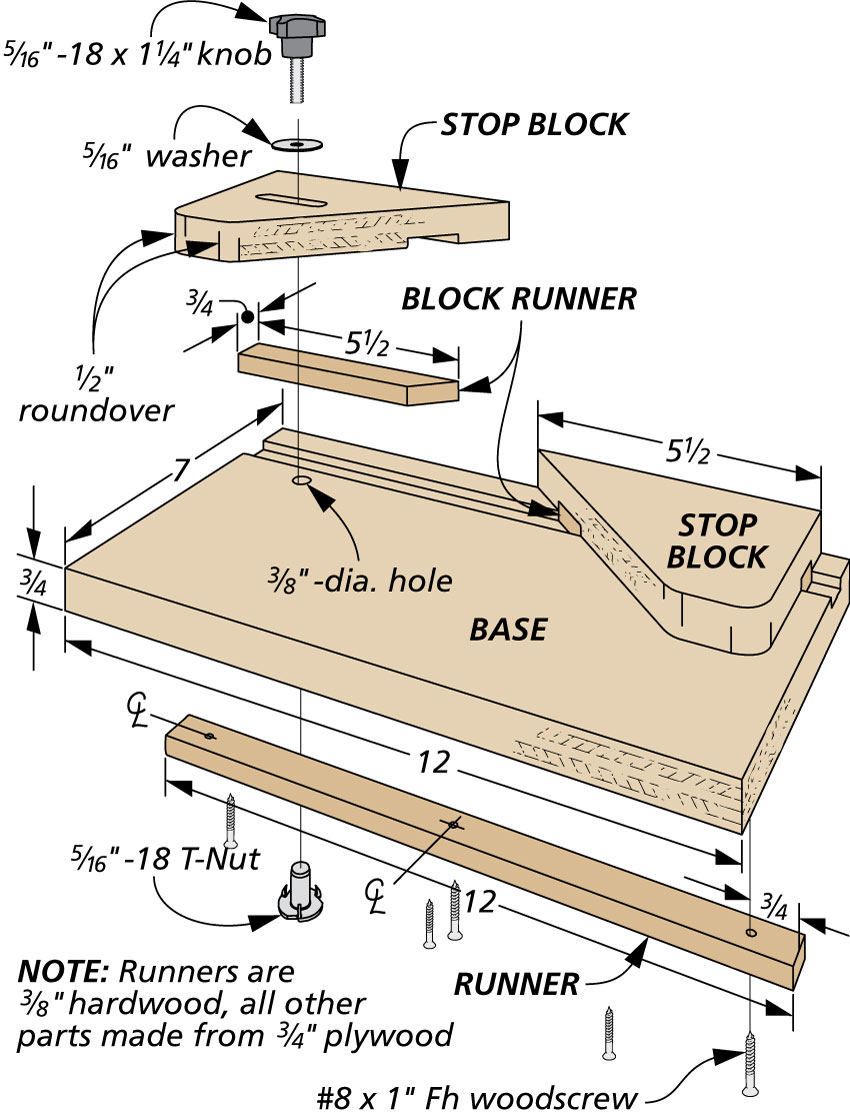

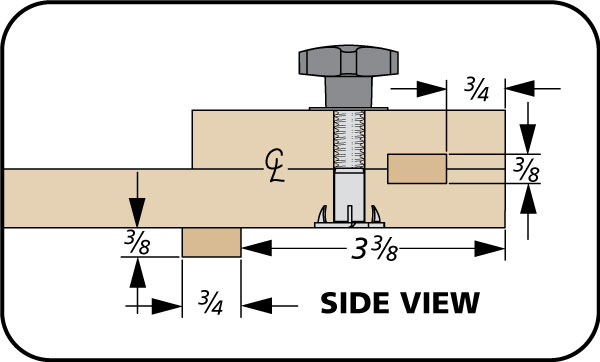

The jig is attached to my disc sander and is adjustable through a pair of stop blocks. The stop blocks hold a workpiece at a consistent 45°. One stop block is fixed in place, while a narrow slot in the other allows for adjustability. Loosening a knob lets you to move the stop block to produce different sized chamfers.

Construction.

To build the jig, start by cutting the base out of plywood. A groove houses a set of hardwood runners that are attached to the bottom of the stop blocks. The right stop block and runner are glued in place. A slot is cut in the left stop block.

A T-nut is installed into the bottom side of the base, and a knob holds the left stop block in place. To complete the jig, a hardwood runner is attached to the underside of the base. This runner rides in the miter gauge slot that is on the disc sander table.

A T-nut is installed into the bottom side of the base, and a knob holds the left stop block in place. To complete the jig, a hardwood runner is attached to the underside of the base. This runner rides in the miter gauge slot that is on the disc sander table.