The occasional stool in issue 269 has a number of circular parts in its construction, and the most reliable ways to cut these is to use a router and trammel. A trammel is a long, thin piece that acts as a platform for the router. The end of the trammel pivots at the centerpoint of the workpiece, guiding the router in a perfect circle.

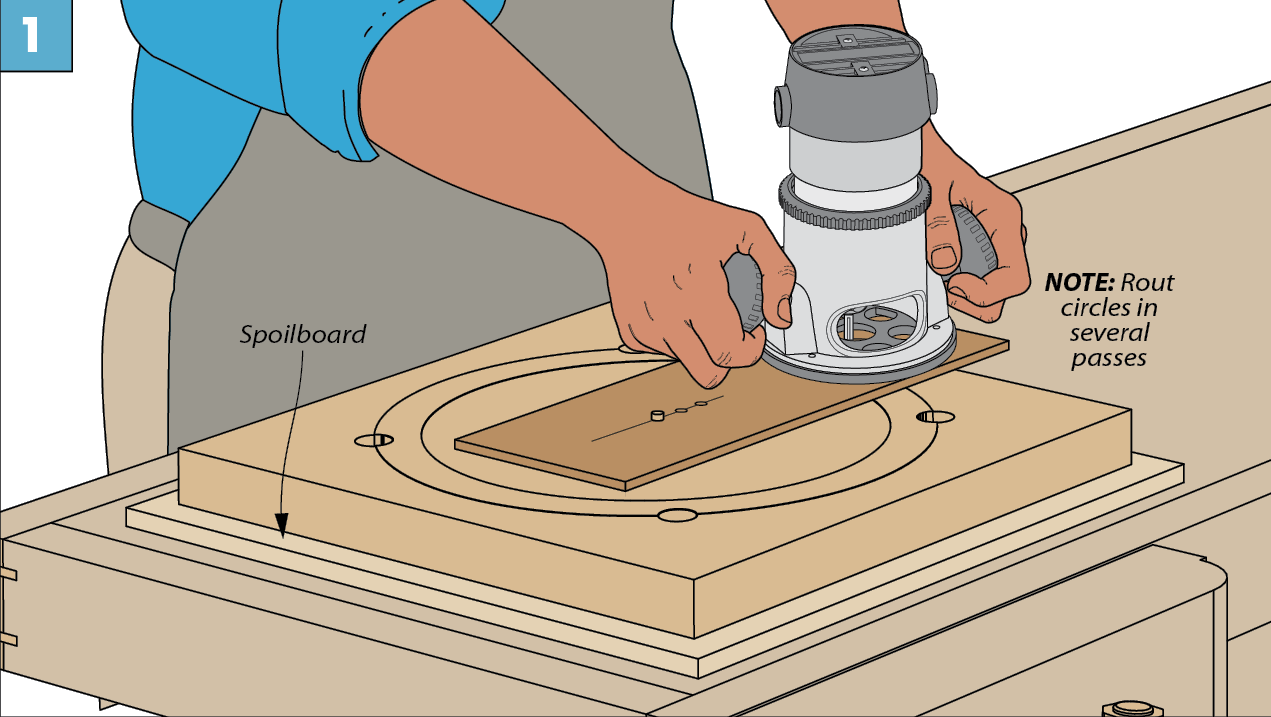

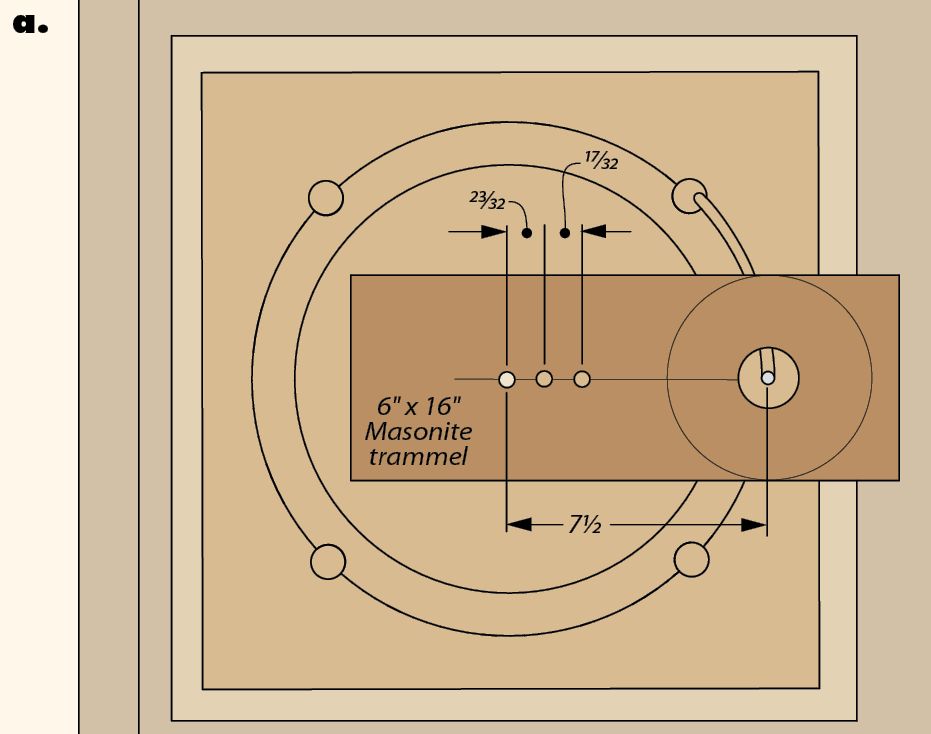

Making the Trammel. A trammel is an easy thing to make. I start by fitting the trammel to the router I’ll be using, then drilling a clearance hole in one end to allow the bit to pass through. From here, I can measure off the bit’s location to make the holes that will guide the actual routing.

These holes will fit a dowel that is used as a pivot pin, keeping the trammel centered on the workpiece. The distance between the pivot point and the router bit determines the size of the circle. I made three holes: one for the perimeter of the stretcher ring, another for the groove to hold the reed spline (detail ‘a’ below) and one to clean up the inside. With these done, it’s time to rout.

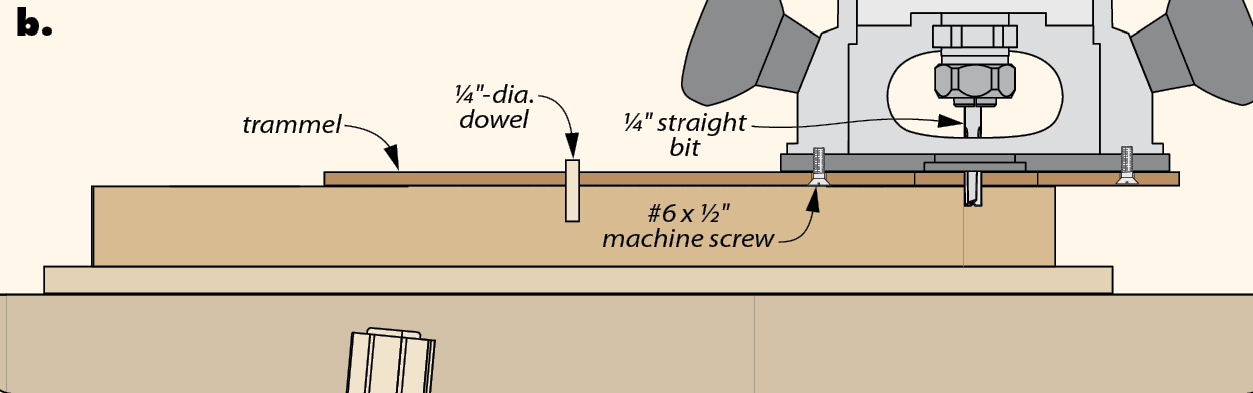

Circle Routing. First, secure your router base to your trammel (detail ‘b’ below). Then, find the center of the workpiece and drill a hole to mount the dowel as the pivot point. Before you start routing, stick the workpiece down to a spoilboard with double-sided tape. This will keep the pieces in place after making the final pass.

Fit the trammel over the appropriate pivot point, then rout between the holes to create the perimeter of the seatpan. Don’t get too hasty here: limit yourself to taking off about 1⁄4" at a time to keep stress off the motor and bit. Once you’ve finished, rout the groove for the reed spline. Finally, the inner diameter can be routed just as the outside was.