I’m one of those woodworkers cursed with having to wear bifocals. So it’s really tough for me to get the holes in the sanding disks lined up with the dust collection ports on a random-orbit sander and to get them back in the container they came in. The simple jig shown here solved both problems.

I’m one of those woodworkers cursed with having to wear bifocals. So it’s really tough for me to get the holes in the sanding disks lined up with the dust collection ports on a random-orbit sander and to get them back in the container they came in. The simple jig shown here solved both problems.

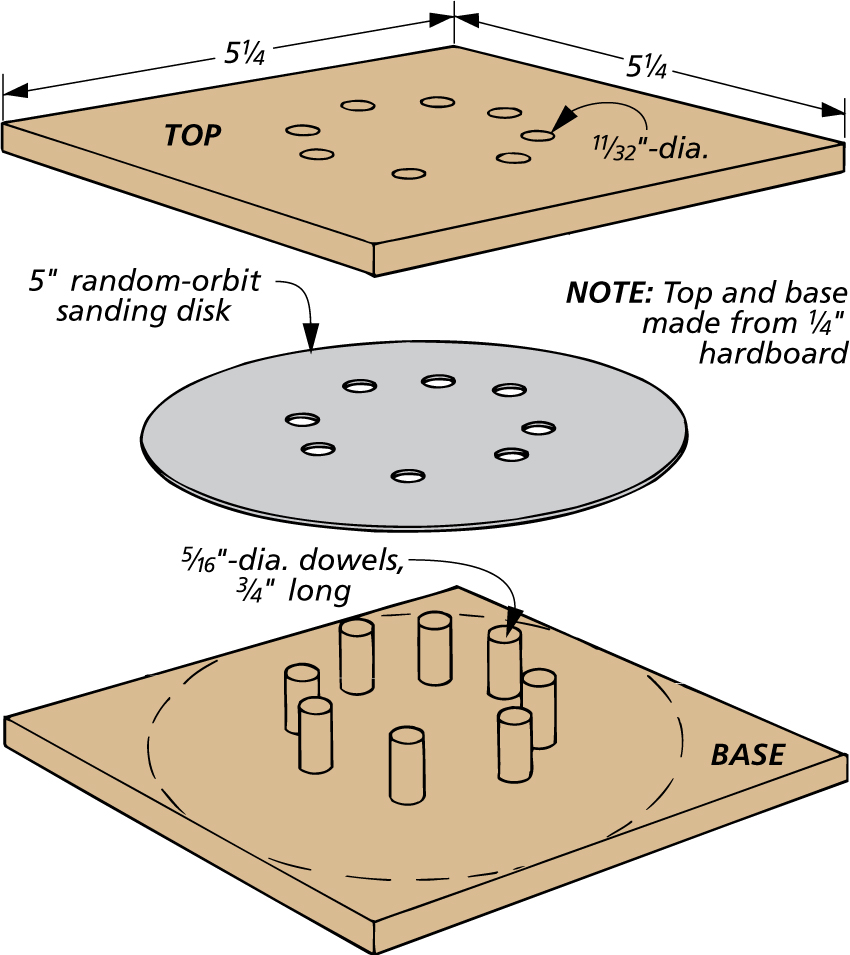

A jig for loading & storage. The jig is built using a couple of small parts of hardboard, along with some dowels. Using a sanding disk, I marked the location of the dust collection holes on both the pieces of hardboard. One will become the top and the other will be the base. After drilling holes in each, I installed dowels into the base holes. To aid sliding disks on, I rounded over the top of the dowels with some sandpaper.

A jig for loading & storage. The jig is built using a couple of small parts of hardboard, along with some dowels. Using a sanding disk, I marked the location of the dust collection holes on both the pieces of hardboard. One will become the top and the other will be the base. After drilling holes in each, I installed dowels into the base holes. To aid sliding disks on, I rounded over the top of the dowels with some sandpaper.

Storage and loading. To store the disks, I simply fit them over the dowels (sandpaper side down) and slide the top down over them. They stay clean and organized, and the cover keeps them flat.

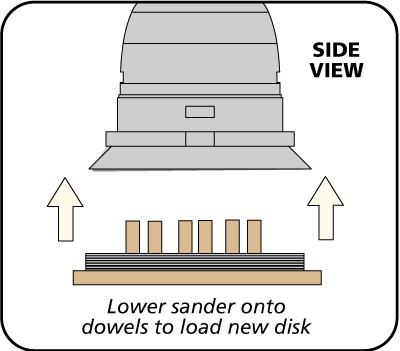

When I need to install a new sanding disk, I remove the top, position the sander’s dust ports over the dowels, then slide the sander down until the pad’s “hooks” engage the disk’s loops. The holes align perfectly, the disk stays in place (because it’s clean), and I’m quickly back in action.

Storage and loading. To store the disks, I simply fit them over the dowels (sandpaper side down) and slide the top down over them. They stay clean and organized, and the cover keeps them flat.

When I need to install a new sanding disk, I remove the top, position the sander’s dust ports over the dowels, then slide the sander down until the pad’s “hooks” engage the disk’s loops. The holes align perfectly, the disk stays in place (because it’s clean), and I’m quickly back in action.

Subscribe Today