Start With a Plumbing Fitting

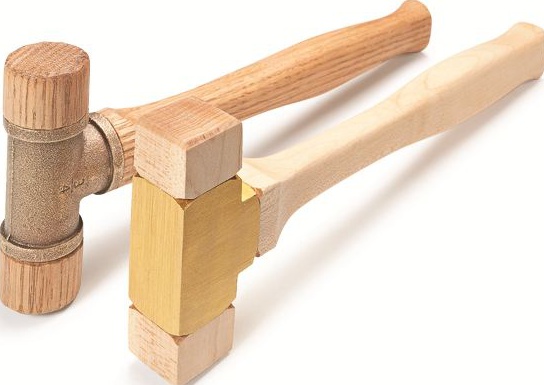

While browsing the plumbing aisle of the hardware store, it occurred to me that a brass pipe tee fitting would make a great mallet for the shop. I found two types, as you can see — a round cast fitting and a square machined fitting.

Make Threads in Wood

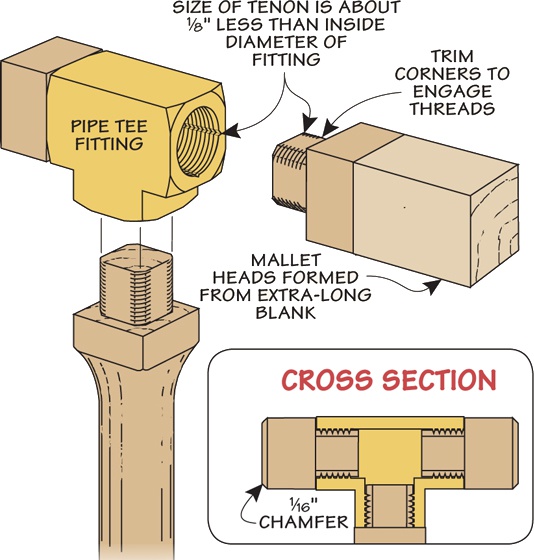

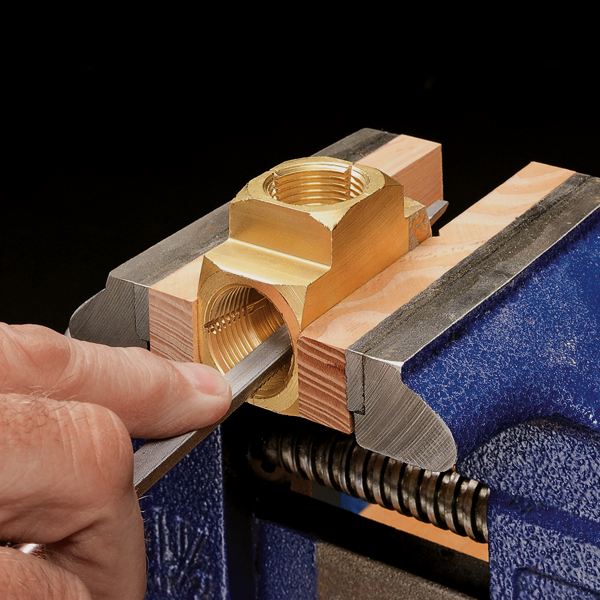

The trick is to figure out a way to fasten the heads and handle to the fitting. I wanted to be able to replace them when necessary, so gluing them in with epoxy was out of the question. Instead, I used the fitting to cut threads on the wood parts for a solid connection. To do this, I filed notches in the threads with a three square file. This forms cutting edges to slice through the wood fibers and create threads.

Add Heads & Handle

Next, I formed a square tenon on an extra-long blank for the heads and handle. The tenon is slightly undersized and the corners are trimmed with a chisel, as shown in the drawing below. This provides enough “meat” to engage the threads of the fitting. After installing the blanks into the fitting, you can cut them to length and shape them to suit your tastes and comfort.