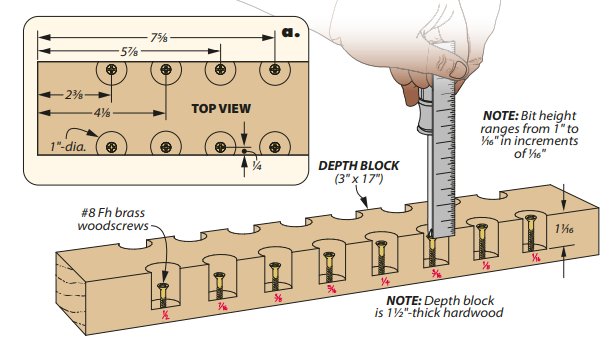

Setting an accurate depth of cut on a router bit is a fussy task. Precise routing usually takes some test cuts, unless you have a depth gauge. Rather than buy a commercial option though, I figured I could make a better one myself — which is exactly what I did.

As you can see, it’s just one block with a series of cutouts. I drilled the holes, then trimmed each edge to form the openings. Now it was just a matter setting the heights for the screws. The screws act as the depth stops. I searched through my collection of miscellaneous screws for ones that would sit about where I want them and have a little extra thread to hold in the wood. After collecting screws and drilling pilot holes, I used a screwdriver and small ruler to fine-tune their heights by hand.