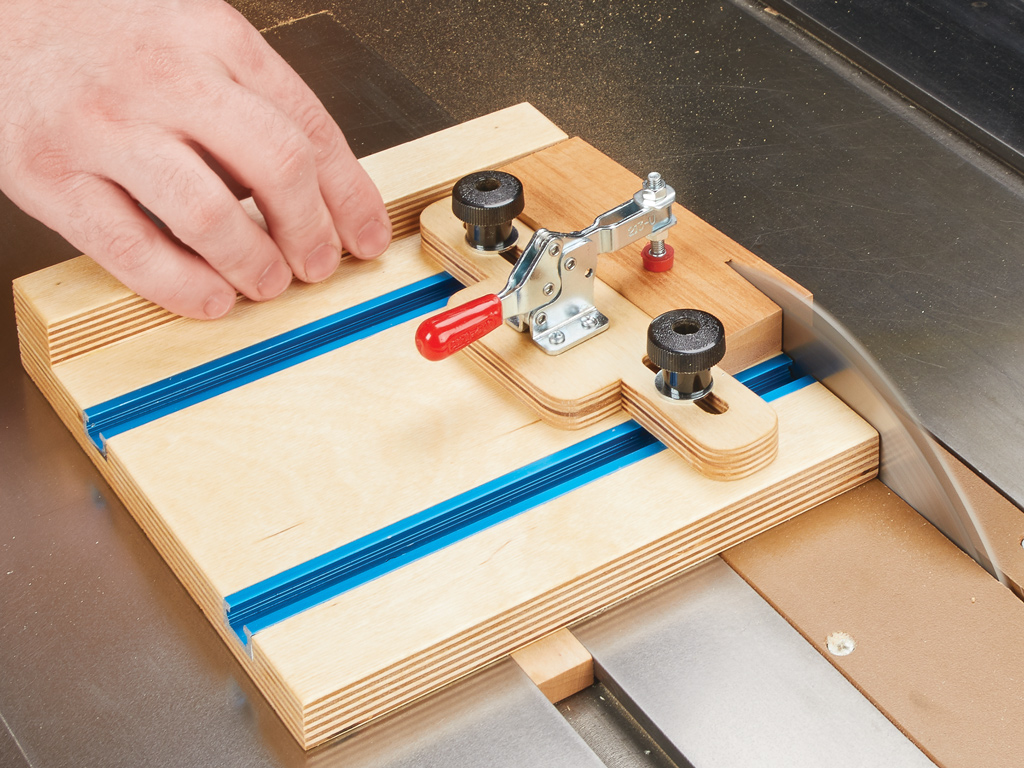

The table saw is my preferred method to size parts. For the small toys I make, it’s perfect to cut a lot of the same part, and quickly too. However, cutting odd angles or tapers safely at the table saw, especially on small parts, can be tricky. At least, until I built the jig that’s shown above.

The table saw is my preferred method to size parts. For the small toys I make, it’s perfect to cut a lot of the same part, and quickly too. However, cutting odd angles or tapers safely at the table saw, especially on small parts, can be tricky. At least, until I built the jig that’s shown above.

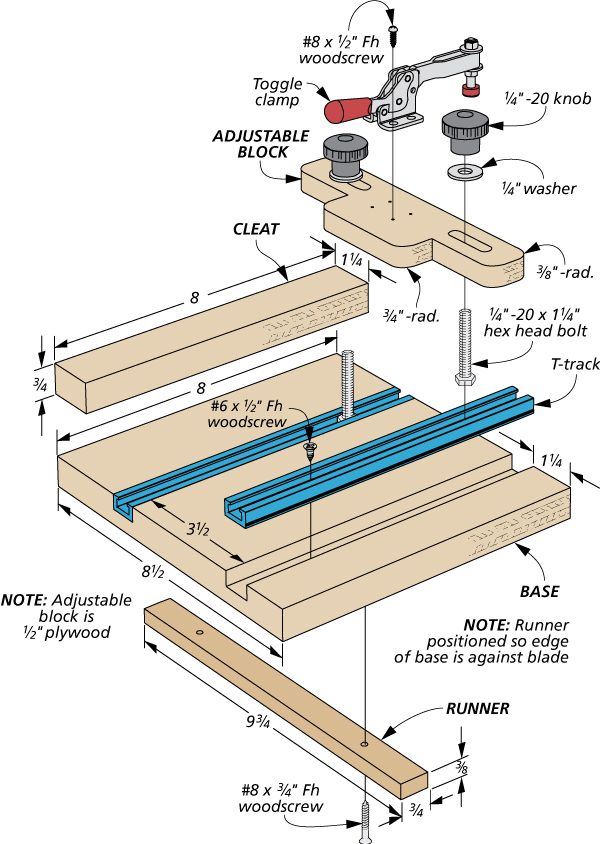

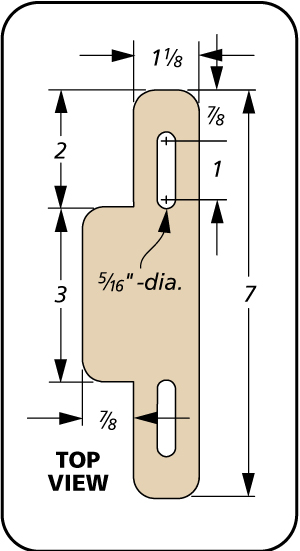

Adjustable Clamping. The taper jig starts off like a small crosscut sled. A runner is connected to a plywood base. A cleat is attached along the back edge to hold workpieces, as well as give you a grip on the sled. The real heart of the jig is an adjustable block that pivots in T-tracks recessed in the base. The block has a toggle clamp to hold down parts and a couple of knobs lock the block in place once it’s adjusted.

Adjustable Clamping. The taper jig starts off like a small crosscut sled. A runner is connected to a plywood base. A cleat is attached along the back edge to hold workpieces, as well as give you a grip on the sled. The real heart of the jig is an adjustable block that pivots in T-tracks recessed in the base. The block has a toggle clamp to hold down parts and a couple of knobs lock the block in place once it’s adjusted.

Quick & Easy Adjustment. Using the jig is just like using a full-sized taper sled. I start by laying out the taper or angle on the workpiece and aligning it with the edge of the sled. With the workpiece butted against the cleat, it’s a simple matter of bringing the adjustable block tight against the workpiece and locking it in place with the knobs. After the toggle clamp is locked down on the workpiece, I can make my cut. The best thing of all is that the jig stays set at that angle, and I can make a repeatable cut.

Quick & Easy Adjustment. Using the jig is just like using a full-sized taper sled. I start by laying out the taper or angle on the workpiece and aligning it with the edge of the sled. With the workpiece butted against the cleat, it’s a simple matter of bringing the adjustable block tight against the workpiece and locking it in place with the knobs. After the toggle clamp is locked down on the workpiece, I can make my cut. The best thing of all is that the jig stays set at that angle, and I can make a repeatable cut.

Subscribe Today