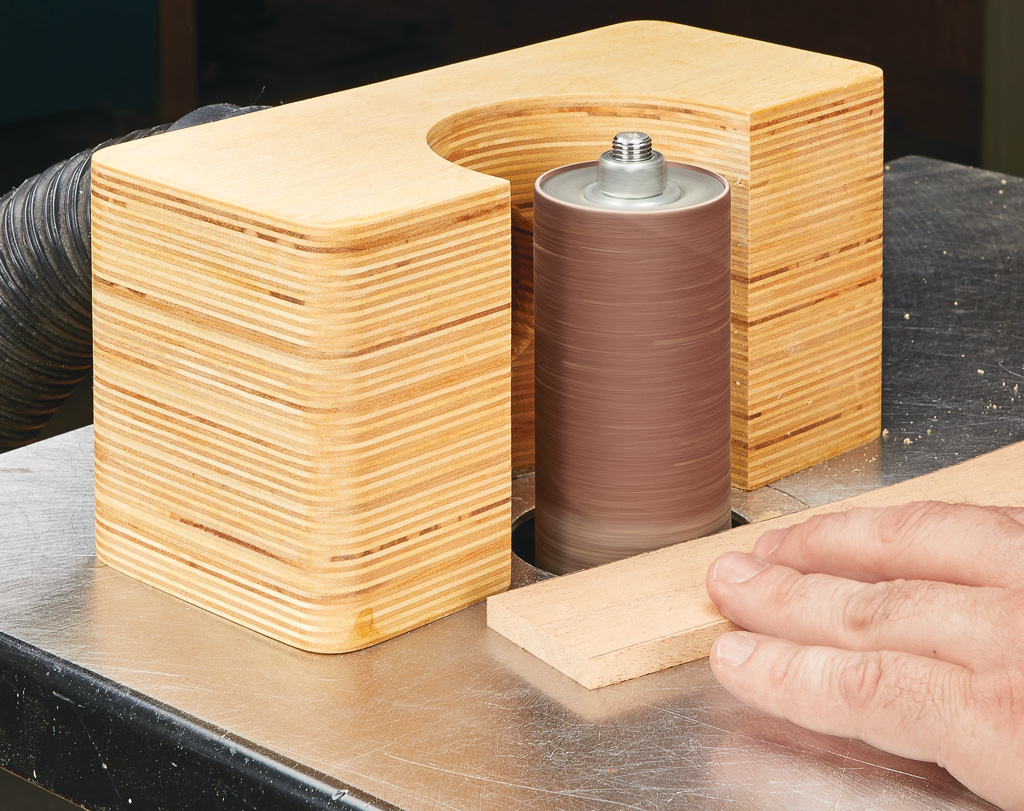

One tool that I had never dreamed I would use as much as I do is my spindle sander. It’s great for getting into tight radii and helping smooth out curves. The dust collection that came with it is lackluster, however. I was always left with a fine layer of dust covering everything within reach of the sander. That’s when I decided to come up with the dust helper you see above.

One tool that I had never dreamed I would use as much as I do is my spindle sander. It’s great for getting into tight radii and helping smooth out curves. The dust collection that came with it is lackluster, however. I was always left with a fine layer of dust covering everything within reach of the sander. That’s when I decided to come up with the dust helper you see above.

Movable. The dust collection shield has one unique feature that makes it work well. That feature is a pair of rare-earth magnets in the base. Depending on what I’m sanding, I can position the shield where I need it.

Movable. The dust collection shield has one unique feature that makes it work well. That feature is a pair of rare-earth magnets in the base. Depending on what I’m sanding, I can position the shield where I need it.

A hole on the back side is sized to fit my shop vacuum hose. The combination of the shop vacuum and the ease of positioning the shield collects almost all of the dust.

A hole on the back side is sized to fit my shop vacuum hose. The combination of the shop vacuum and the ease of positioning the shield collects almost all of the dust.

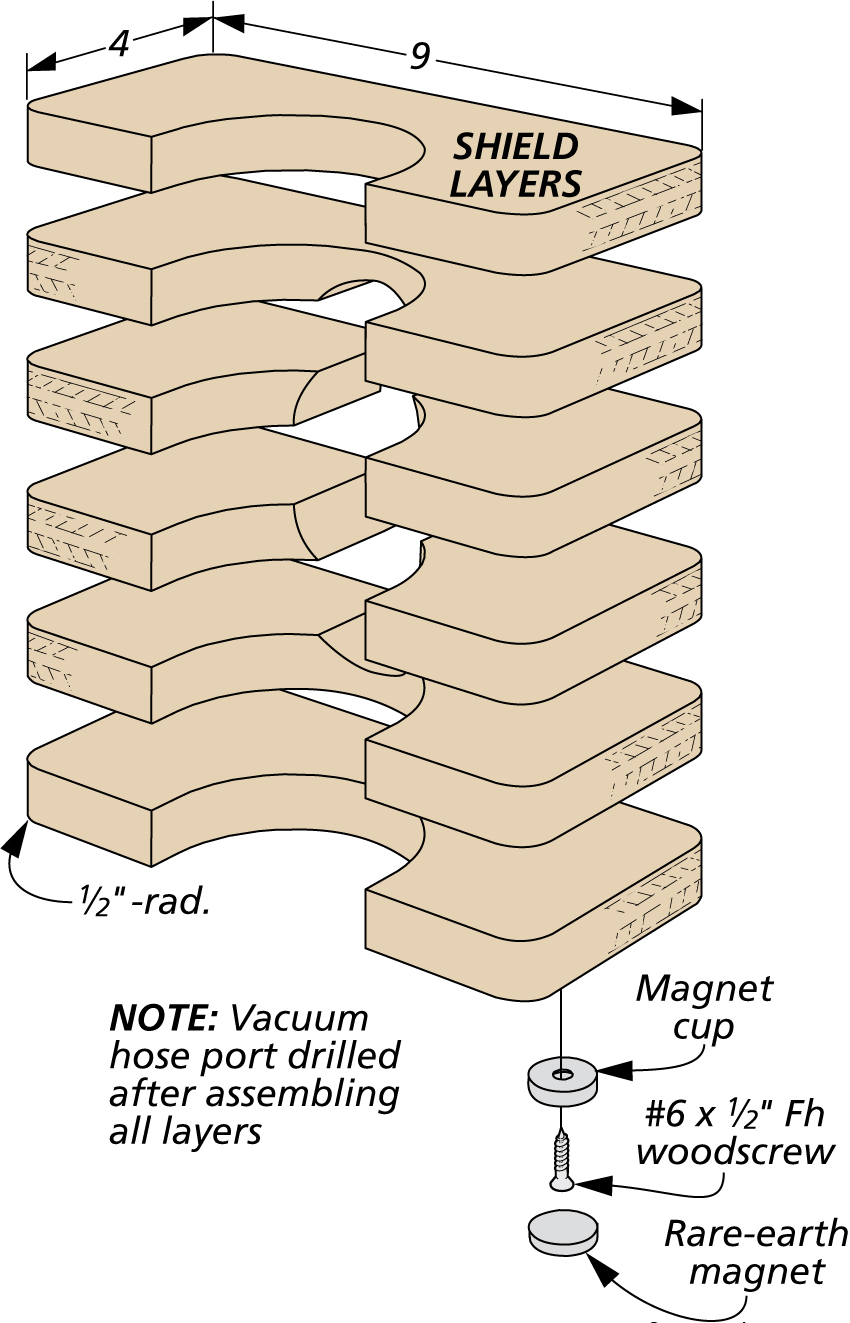

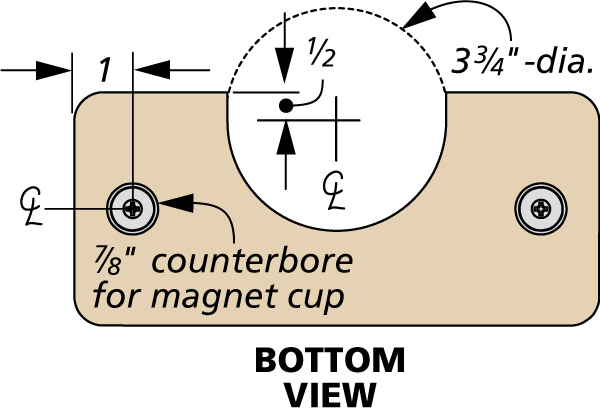

Layers of plywood. The shield is built by gluing up multiple layers of plywood, making sure it’s taller than the spindle. The first layer is shaped at the drill press, and each layer is trimmed using a flush-trim bit (How-To steps below). Finally, a hole for the shop vacuum hose is drilled and magnets installed in the base.

Layers of plywood. The shield is built by gluing up multiple layers of plywood, making sure it’s taller than the spindle. The first layer is shaped at the drill press, and each layer is trimmed using a flush-trim bit (How-To steps below). Finally, a hole for the shop vacuum hose is drilled and magnets installed in the base.

How To: Make The Shield

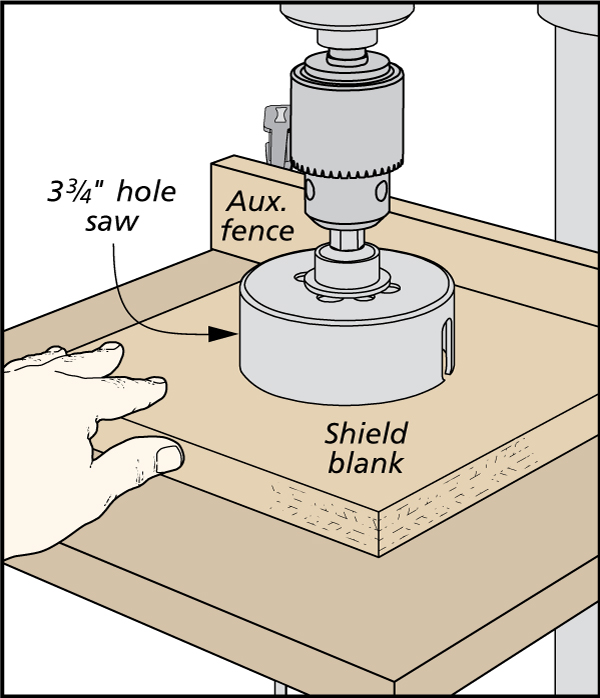

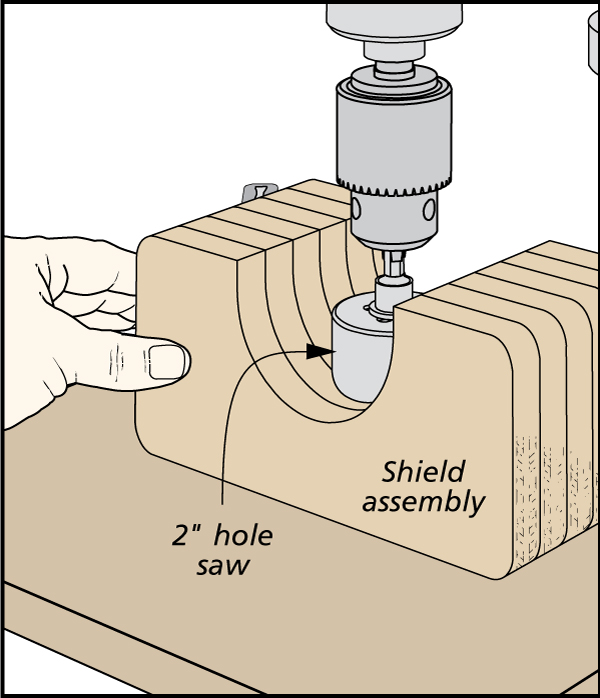

One Blank. Using a hole saw, cut out the hole in an oversized plywood blank. Then, trim the blank to shape.

One Blank. Using a hole saw, cut out the hole in an oversized plywood blank. Then, trim the blank to shape.

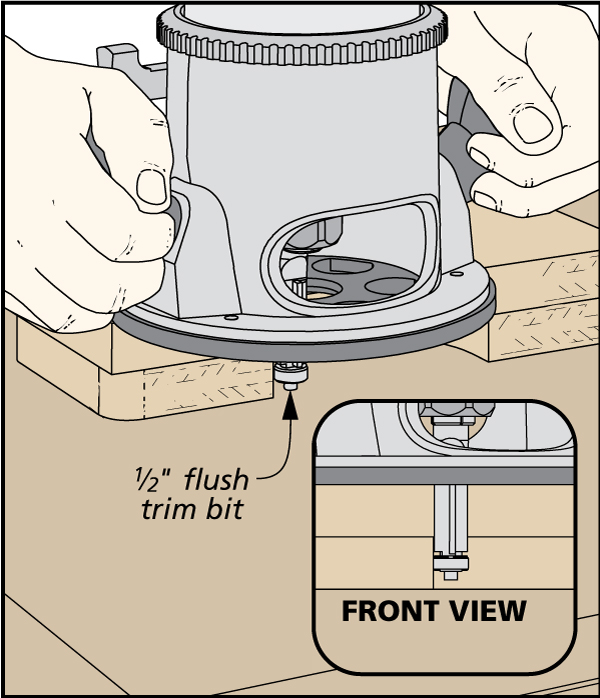

Rout Layers. Add additional layers to the first blank. Using a flush-trim bit, trim each layer to match the previous.

Rout Layers. Add additional layers to the first blank. Using a flush-trim bit, trim each layer to match the previous.

Dust Port. After all the layers are trimmed and the glue is dry, drill a dust collection port using a hole saw.

Dust Port. After all the layers are trimmed and the glue is dry, drill a dust collection port using a hole saw.