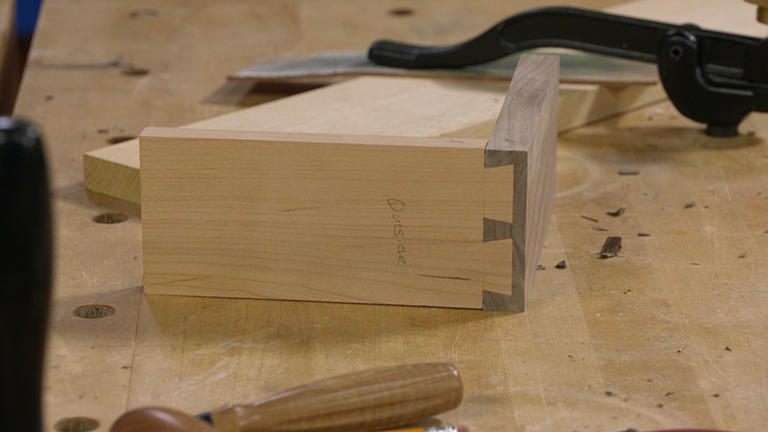

After building my first crosscut sled, I realized how versatile it could be and was excited to expand its capabilities. When I had a project that required box joints, I realized a finger joint jig was the perfect add-on to my crosscut sled. This box joint jig is easy to make and takes most of the trial and error out of cutting box joints. And best of all, it’s much smaller and easier to store than a standard box joint jig.

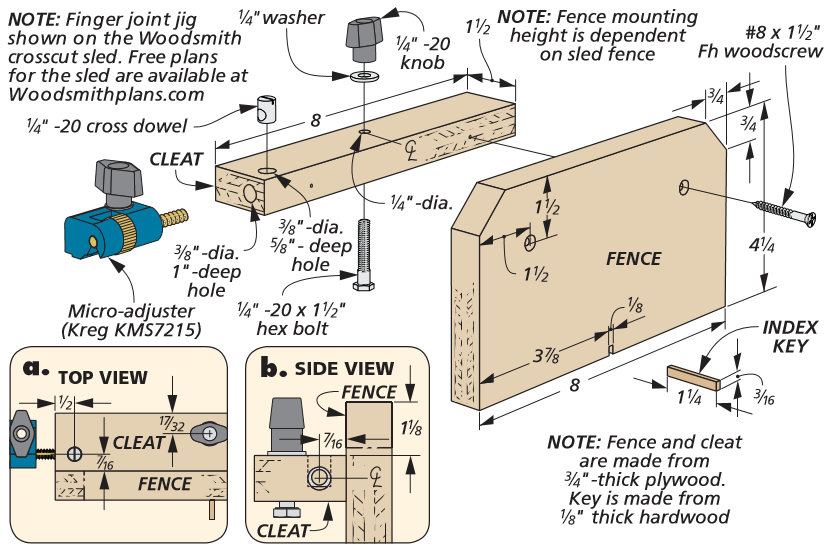

The jig consists of a fence and cleat that slides along the top track on my sled. The micro-adjustment mechanism allows you to fine-tune the jig and takes the guesswork out of cutting box joints. The fence is a piece of plywood with an index key glued into a slot. The width of the index key should match the desired size of the box joints. Because I make different size box joints, I made a few different fences that can be swapped out quickly.

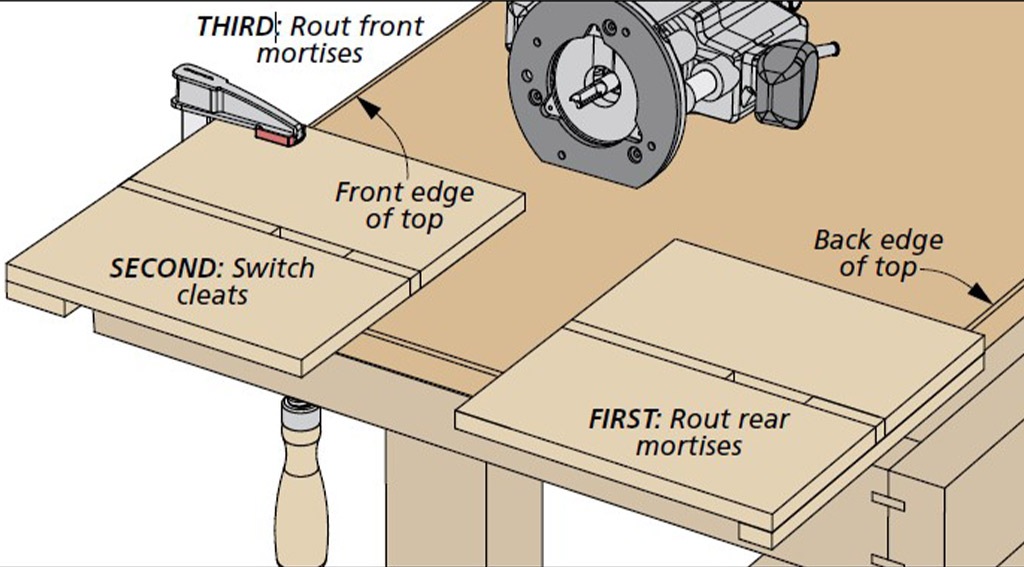

Using the jig is a simple process and similar to other box joint jigs you may have used. It slides onto the track and its position can be fine-tuned with the micro-adjuster. If I’m cutting larger box joints, I use a dado blade. But for most joints, I leave my rip blade in the saw. After a test cut to confirm the setup is correct, I know that I’m going to have perfect box joints every time.