Chances are, one day you’ll take on a project that requires thin stock. It could be a box with 1 ⁄ 2 "-thick sides or a chest with small drawers made from 1 ⁄ 4 " stock. A quick price check at the lumberyard (where thin stock is usually sold by the square foot) will show you how expensive it can be to buy thicknesses less than 3 ⁄ 4 ".

Of course, you could always plane down thicker stock. But this method is pretty wasteful and leaves you watching a big chunk of your woodworking budget go swirling into your dust collector. That’s why learning how to resaw on your band saw is a good investment of time and money.

START WITH THE RIGHT BLADE. Before you get started, there are a few things to do. The first step is to install the correct type of blade for cutting through the width of a board.

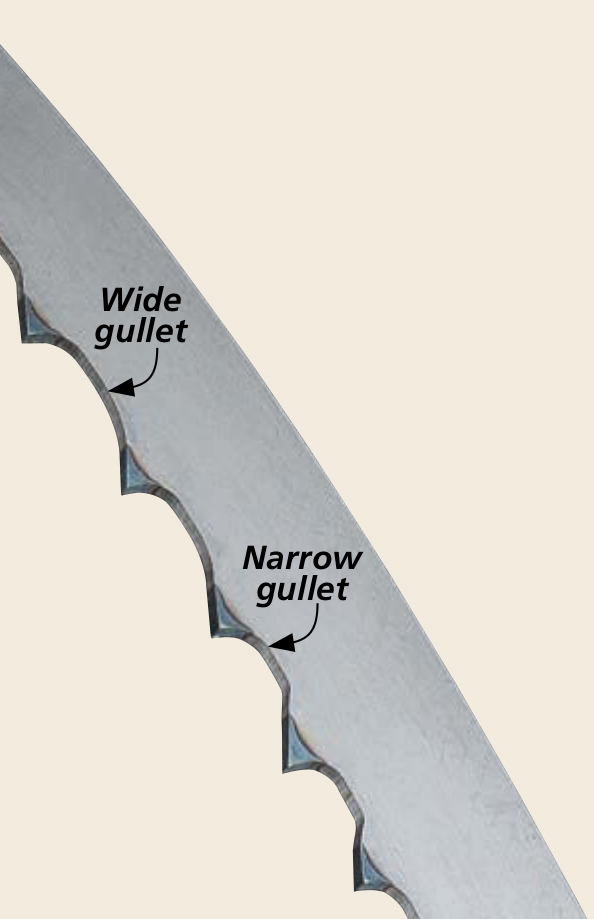

Resawing involves making rip cuts in the face of a wide board. So just like you would on the table saw, you’ll want to select a blade with fewer teeth per inch (TPI) than the blades you use for crosscutting or cutting curves. For most 14" band saws, a 1 ⁄ 2 "-wide blade with 2-3 TPI is a good choice.

One option is the Wood Slicer from Highland Woodworking (photo below). It has the right tooth count and also features a variable tooth pitch.

This means that the spacing of the teeth is irregular. It helps reduce vibration, resulting in a much smoother cut. Priced at around $25, it’s a great blade for occasional resawing.

Once you’ve mounted the blade in your saw, you need to adjust the tension. Unfortunately, the scale on your saw isn’t a very reliable indicator of how much tension the blade requires. The illustration below shows an easy way to determine the right amount of tension. When set properly, the tension keeps the blade rigid enough to cut through a wide workpiece without it deflecting or making a barrel cut.

Finally, make sure the table is square to the blade and set the thrust bearings and guides according to the saw’s instruction manual.

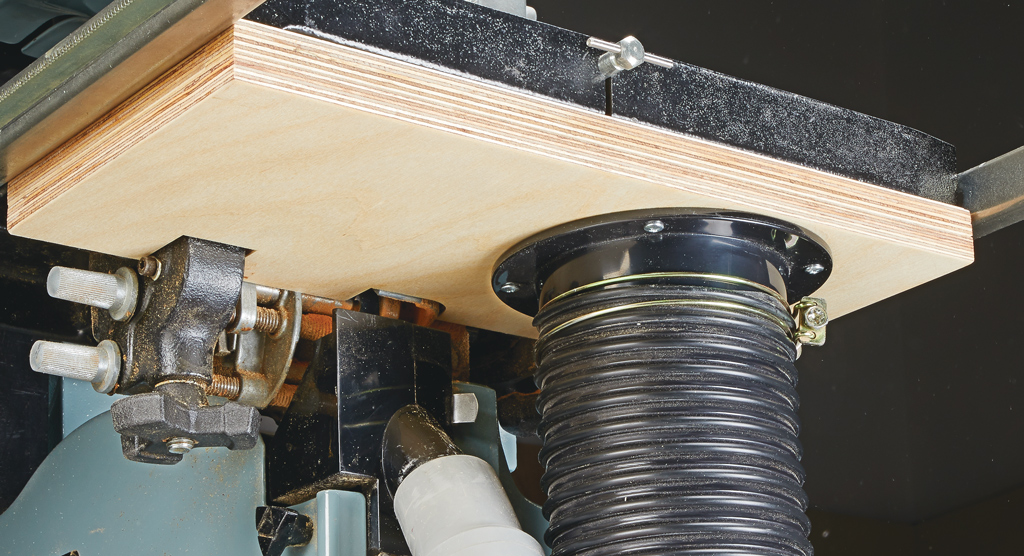

FENCE. One piece of equipment that’s essential for getting good results when resawing is a fence. If your saw didn’t come with a fence, it’s easy enough to make one. Most of the time, I prefer to use a tall, flat fence like the one shown at the far right in the photo above, and in the main photo.

A tall, shop-made fence simply clamps to the saw table and provides support for the workpiece. This is especially important when resawing thin stock or veneer.

BLADE DRIFT.

A fence alone won’t necessarily guarantee a straight cut, however. Most band saw blades tend to veer slightly to the left or right when cutting. This is known as blade drift. The amount of drift varies with every blade, but you can compensate for it by clamping your fence to match the drift angle. The drawings below show you how to do this.

SINGLE-POINT FENCE. Another way to overcome blade drift is to use a single-point fence like the one shown in the left photo above and in the margin. To use a single-point fence, you simply scribe a line on the edge of the workpiece and cut on the line by pivoting the workpiece to match the angle.

SETTING THE FENCE TO COMPENSATE FOR BLADE DRIFT

FEED RATE & TECHNIQUES. With either style of fence, your saw will help you determine the feed rate for resawing. As a rule, you should push the stock through the blade almost as fast as your saw allows without bogging down or making unusual noise. This gives you the best result and helps prevent wearing out the blade prematurely.

After making a few cuts, you’ll develop a feel for the right speed. When you can no longer cut at this rate, it’s a good bet the blade is getting dull. The biggest frustration with resawing is how quickly a blade becomes too dull to cut effectively. One way to get longer life is to buy a carbide-tipped blade. The box below has the details.

CUT & PLANE. To save yourself some work, it’s a good idea to joint or plane the face of the workpiece between each cut. This way, you’ll have a flat reference face when it’s time to clean up the pieces.

Once you get the hang of resawing, it will become an indispensable skill allowing you to make the most of your lumber.

Upgrade: Lenox Carbide-Tipped Blades

Regular band saw blades are made from high-carbon or highspeed steel. These are good choices because they’re flexible enough to provide a long life while bending around the wheels of the saw. And for cutting curves in thinner stock, they hold up pretty well. But when it comes to resawing, these teeth dull very quickly, often in as little as a couple hours of cutting time.

Fortunately, there’s a solution — carbide teeth. By brazing small carbide teeth to the high-speed steel band, you get the best of both worlds. Of course, these blades come at a pretty steep price. The Lenox Woodmaster CT, shown above costs about four times the price of the Wood Slicer blade but lasts about six times longer. If you do much resawing, it quickly pays for itself.