The Overlooked Logs

Often times, sawmills and loggers want straight, fresh logs to cut into lumber. And, it makes sense. When you're sawing lumber that's getting sold, you want a consistent run-of-the-mill boards. This means getting the highest quality (highest grade) stock you can from a log. There are times, however, when an ugly duckling log can hold a suprise. Meet exhibit A.

This log is from a locust tree. It was cut about 2 years ago and has been laying in a pile ever since. This was one of two locust logs I got from this group. Personally, I don't use much locust. It's a pretty wood, but the salmon-brown-cream doesn't jive with most of the stuff in my house.

However, our former shop craftsman, Dana Myers, had a table he was building out of locust and I knew he needed a little more to finish the base. So, I gave him a call and told him I had some logs to saw if he wanted the lumber. Of course, in all of his ample post-retirement time (I say that sarcastically - If you've met Dana, you know his wife is keeping him busy with projects), Dana said absoltuley and he came out to give me a hand while we cut it up.

The first log was a nice, straight piece of locust about 17" in diameter. We removed a small crotch section (to be cut into charcutrie boards at a later date) and loaded it onto the mill. A handfull of cuts revealed a half a dozen 6/4" boards and one monster 3.5"-thick board for legs. All of them left live edge.

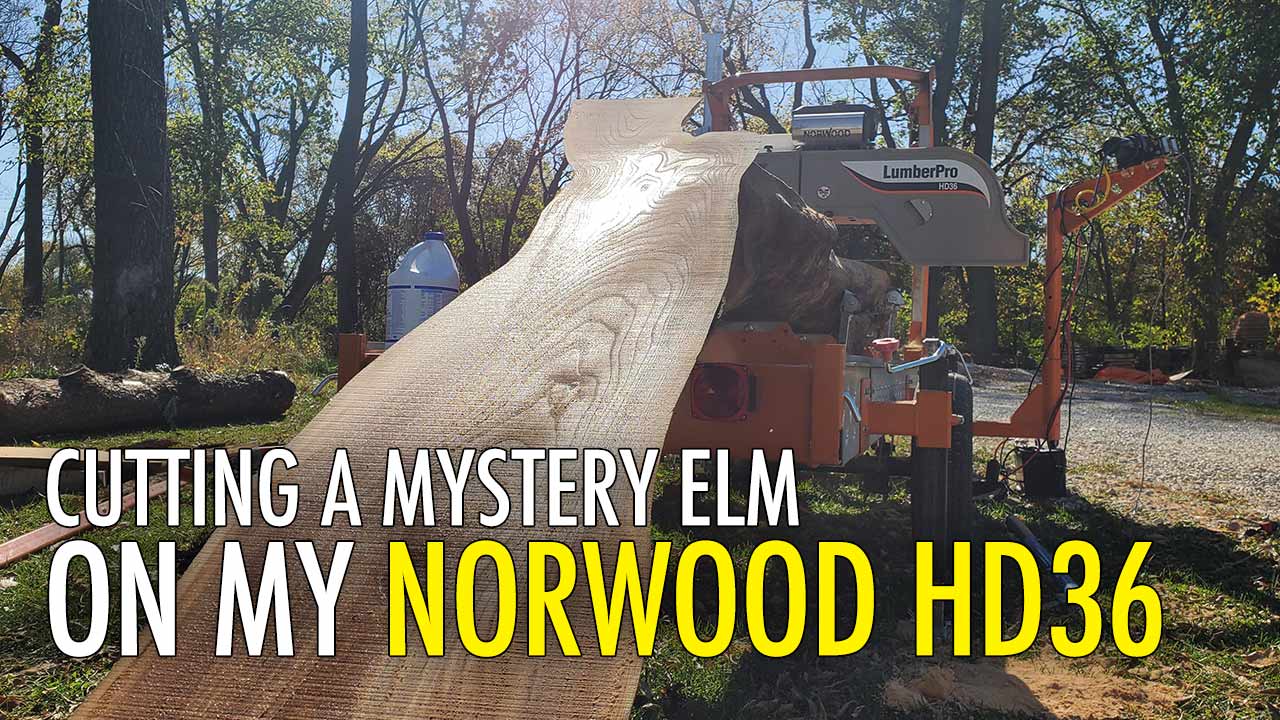

The final log was the one pictured above. It was a twisty, knotty, half rotten looking log. You can even see the hundreds of bug holes in it from when it was standing and woodpeckers attacked it. Most people wouldn't give it the time of day, but Dana and I wanted to see what this this knotty, lumpy, ugly log had hidden inside. Locking it onto the mill, we made a handful of cuts leaving us with 7 or 8 beautiful 2"-thick pieces of locust. Yes, there were a few soft spots, but talk about beautiful grain! I may even have to keep one or two of these for myself! - Logan