Starting a new woodworking project is always exciting. And one of the best parts is going to the lumberyard to choose the wood to become parts of that project. While there’s no question that selecting boards is fun, it’s also a process that many woodworkers don’t devote enough time to. After all, the lumber you choose will not only determine the appearance of the project, but also play a role in how easily it goes together.

BETTER BOARD CHECKLIST. With this in mind, I’ve created a checklist of things to consider as you look over boards. Whether you’re a beginning woodworker or just need a refresher course in what to look for, these lumber-buying tips will help ensure great woodworking results every time.

TIP #1: WATCH YOUR FIGURE. As you pick through boards in a lumber rack, it’s easy to get caught up in the beautiful figure pattern of an individual board. But it’s important to remember that most of these boards will get cut up, moved around, and reassembled into something functional.

As a result, the figure that looks so attractive on a board by itself might get a little busy on a piece of furniture. Considering that, I usually opt for boards with straight, consistent grain when I’m building furniture projects (photo above).

There’s no right or wrong when it comes to the figure you choose. Just remember that with subtle figure, you are more likely to notice the design of the project. With highly figured wood, you’ll probably notice the wood first.

TIP #2: KEEP AN EYE ON COLOR. Just as with figure, color is an important consideration when it comes to choosing boards. You might think that buying boards of the same wood species would take care of this, but as you can see below, there can be some wide variations in color even among boards of the same species.

To help in selecting lumber with the right figure and color, a good trick is to pull boards down from the rack and line them up side by side. This way, you can really see how consistent the look will be from board to board.

TIP #3: ENVISION PROJECT PARTS. Try to have a clear idea of what parts you’ll need for the project. Then, as you select boards, you can keep this in mind. For example, you may want to cut all the rails and stiles of a face frame out of the same board.

Once you’re home, lay out the individual parts in chalk, so you’ll be sure they end up where you want in the finished project (see the photo below). Also mark knots, splits, and other defects, so you’ll know to avoid these areas. If necessary, you can use a jig saw to cut out these individual parts before trimming them to final size with your table saw.

TIP #4: DON’T GET DONE IN BY DEFECTS. Finally, check each board for defects before you buy it. Some shortcomings may render the board unusable for your project. You can see common defects in the illustrations below.

In many cases, a defect doesn’t mean that you can’t use the board. It just means that you’ll have to make considerations to work around it. When it comes to checks and knots, for example, you might be able to cut them off or plan around them. If a board is cupped, you can sometimes rip it into narrower, flatter pieces. Boards with a bow, crook, or mild twist might need to be crosscut into shorter boards to be usable.

Of course, it’s best to choose boards without defects if possible. To check a board for bow or twist, sight down its edge (the first photo in this post). To check for crook or cup, look down the face. These simple steps will ensure that you end up with the best lumber for every project, every time.

Understand Thickness

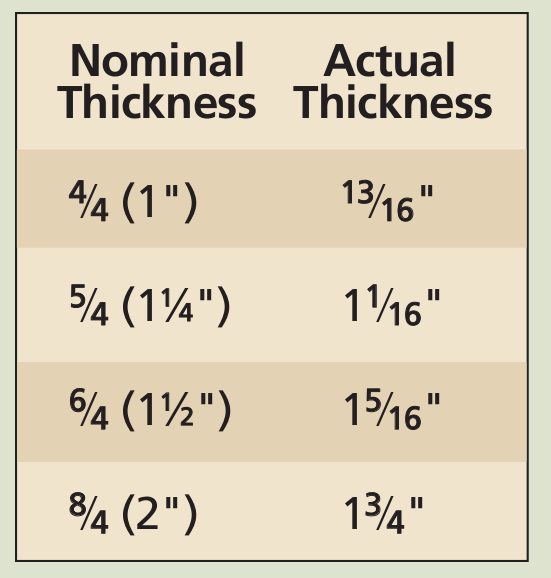

Ever wonder why a “4/4” board, is actually closer to 3⁄4" instead of 1"? The reason is that rough boards are a true 1" thick when cut at a mill, but most lumberyards surface both faces to end up with a board that’s smoother and looks nicer. The result is that the actual thickness of the board is less than its “nominal” thickness.

To help end confusion about thickness, most lumberyards follow a standard when it comes to the nominal and actual thickness of lumber. So when you pick out a board labeled in “quarters,” it should closely match the actual thickness shown in the chart below.