Rip and crosscut — that’s what most people use the table saw for. And a good portion of every project involves cutting boards or sheets of plywood into smaller pieces. But table saws make great joinery tools as well. Grooves, dadoes, rabbets, tenons … you know the drill.

More complex joinery — dovetails and drawer joints — are often the domain of the router. However, we look at two jigs in this episode that you can make for your table saw that put these joints within easy reach.

For the dovetail jig we also talk about another upgrade: a dovetail table saw blade. Several blade makers will custom grind a blade to cut a flat-bottomed kerf when tilted at a specific angle. This blade is used when cutting the tails of the joint. When it’s time to cut the pins, you can switch out the blade for a single standard blade (or a dado). A moveable fence on the jig is set to angle the workpiece to match the slope of the tails.

My first impression was that this process would entail a significant amount of fussing to get pins and tails aligned. As you’ll see, the spacers on the jig let you get a solid fit right from the start.

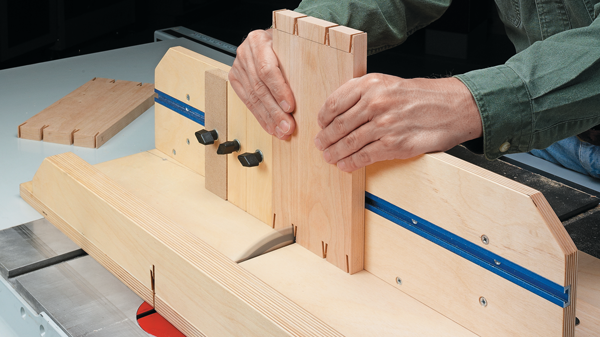

Woodsmith often turns to a locking rabbet joint to make drawers. I’ll grant it’s not as flashy as dovetails. But this joint has a lot of interlocking surfaces that make it a practical hard worker. Chris Fitch, our Creative Director when he’s not moonlighting on the show, designed this jig to make the joint with a single blade setup in your saw.

Woodsmith often turns to a locking rabbet joint to make drawers. I’ll grant it’s not as flashy as dovetails. But this joint has a lot of interlocking surfaces that make it a practical hard worker. Chris Fitch, our Creative Director when he’s not moonlighting on the show, designed this jig to make the joint with a single blade setup in your saw.

A series of stops and a vertical fence combine all the operations into a sled-based design. Logan steps through how to use the jig to make a locking rabbet. But you’ll want to make sure to download the plan to see how to cut other joints just as easily.

BONUS TIPS: Over time, a table saw’s surface can start to look a little road weary. It’s just about cosmetics. A smooth, clean saw table helps you make better cuts, too. Here’s how to bring back the shine.

Watch the Episode: If the Woodsmith Shop isn’t on in your area, contact your local public television station. Or stream it here.

Download the Step-by-Step Plans for this episode: Table Saw Dovetail Jig Locking Rabbet Jig

A crosscut sled supports a workpiece throughout a cut. The result is a smooth, square cut. This project improves your table saw’s performance for critical cuts.

A crosscut sled supports a workpiece throughout a cut. The result is a smooth, square cut. This project improves your table saw’s performance for critical cuts.

Tear out occurs when unsupported wood fibers on a workpiece are torn away from the surface. The ugly blemish mars the look of your project. One way to stifle tear out is to use a zero-clearance insert. You can make your own in less than an hour.