Before modern technology took much of the manual labor out of woodworking, hand planes were manufactured in an amazing array of sizes, shapes, and styles. There was a plane for every task - from smoothing boards to shaping moldings to forming joints. Many of the more specialized planes that were once "standard issue" are now obsolete. However, there are a few of these lesser-known planes that still deserve a place in the shop. One of these is the shoulder plane.

WHY A SHOULDER PLANE? Most planes derive their name from their function. A jointer is used for edge jointing, a smoother for smoothing surfaces. So what does a shoulder plane do? Specifically, the name refers to the use of this plane to square up or trim the shoulders of tenons and other joints. But as you'll see, the uses for a shoulder plane go way beyond this single task.

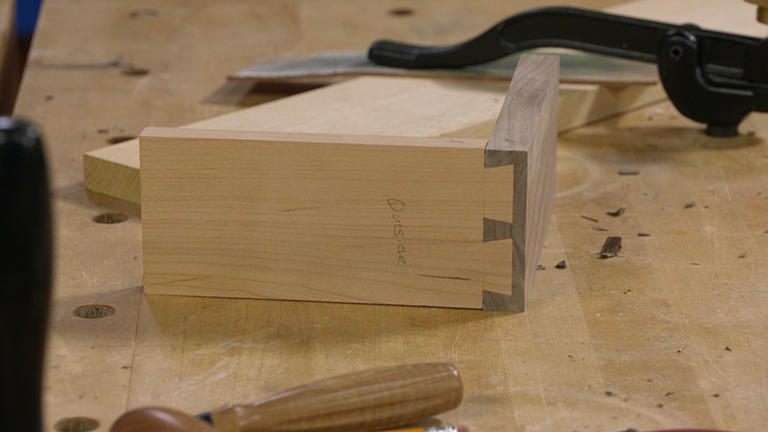

HOW IT WORKS. Although the design of shoulder planes can vary quite a bit, as you can see in the photo above, they all share one notable feature. The cutting edge on the iron of a shoulder plane extends across the entire width of the plane's sole. This allows you to cut right up to a square edge or into a corner as is necessary when trimming a tenon shoulder. But it also opens up many other possibilities as well. I think of my shoulder plane as an all-purpose, joinery-tuning tool.

SHOULDER OR RABBET? The distinction between a shoulder and a rabbet plane is a bit blurry. Like a shoulder plane, a rabbet plane is set up to cut edge-to-edge. The difference is that a rabbet plane is designed specifically to cut rabbets - often having a fence, depth stop, and scoring nickers for making cuts across the grain.

Another difference is that a shoulder plane has a lower cutting angle. This feature allows it to cut end grain or across the grain smoothly and with less effort.

In practical terms, a rabbet plane and a shoulder plane can handle a lot of the same tasks. But all-in-all, a shoulder plane is the more versatile of the two.

WHICH SIZE? Shoulder planes can vary in width from 1/2 " to 1 1/2 ". You'll find that a size in the midrange - 3/4 " to 1" will be the most useful and handle the widest range of tasks. The larger sizes of shoulder planes can be pretty bulky for fine work.

PLANE SETUP. Today's adjustable shoulder planes are much more user-friendly than past types. However, to get the best results, you need a basic grasp of the proper setup. The drawings below illustrate these points.

Since a shoulder plane cuts over the full width of the sole, the cutting edge should be honed perfectly straight across and square to its sides. Most shoulder planes allow only limited lateral adjustment of the iron. If the cutting edge isn't square, you won't be able to set it parallel to the throat.

You'll find that the iron of a shoulder plane is actually slightly wider than the sole. When the iron is installed it should extend a hair beyond both sides of the plane. This allows the plane to cut more effectively into a square corner.

As I mentioned, the cutting edge also needs to be parallel to the throat. If it's not, you won't get a consistent, full-width cut. You can simply eyeball this setting or make test cuts to check it.

Finally, many shoulder planes have an adjustable throat. Since the plane is generally employed for light-duty trimming, you'll be taking fine cuts. Here, a narrow throat is desirable. You'll get a cleaner cut with less tearout.

TECHNIQUE. Using a shoulder plane will come pretty naturally. You'll develop your own feel and form with your particular plane. As with any hand plane, one of the keys is firm control. Since the plane is generally used for light trim work, this isn't difficult.

The smallest shoulder planes often work best as "one-handed" tools - like a block plane. With the larger sizes, a two-handed grip will give you better control. In most instances, I push the plane through the cut. But a shoulder plane also lends itself to a pull cut when this is more practical.

MANY TASKS. All this is just a sampling of the tasks a shoulder plane can handle - from trimming shoulders to smoothing rabbets to shaping contours. Once a shoulder plane finds a home in your shop, it's guaranteed to become a trusted and well-used problem solver.