When it comes to drilling holes for a project, a drill press is usually my first choice. But sometimes, a hand-held drill is more convenient and practical — particularly if you’re dealing with large workpieces that exceed the capacity of your drill press.

The challenge with using a hand drill, however, is drilling straight, square holes (especially deep ones). Fortunately, there’s a simple, low-cost solution. A drill guide, like the one shown above, makes drilling straight holes by hand just about foolproof.

A drill guide is nothing more than a jig that mounts to the end of your drill and guides it in a straight path. Think of it as a set of training wheels for your drill.

There are several makes of drill guides on the market, but they all work on the same principle. The one shown here is my favorite and is made by Wolfcraft

As you can see in the second photo from the top, the design of the Wolfcraft guide is really pretty simple. The jig consists of a pair of guide rods mounted to a round base. A drill chuck mounted in a cross guide slides on these two rods.

To use the jig, you simply attach your drill to the shaft of the chuck. Then insert a drill bit in the chuck jaws. (You can use any type of bit with the guide, up to 2 7 ⁄ 8 " in diameter.) A pair of coil springs helps to support the drill over your workpiece until you apply downward pressure, much in the same way that the springs on a [plunge router](https://www.woodsmith.com/review/best-plunge-router/) work.

A detachable handle allows you to hold the guide in place during use. And a removeable depth stop is included for drilling holes to a precise depth. (You’ll need to remove the springs to use the depth stop.)

APPLICATIONS

There are a number of situations where I find a drill guide invaluable. For starters, it’s really handy if you have to drill holes in a workpiece that’s too large to take to a drill press. A good example is drilling dog holes in the top of a workbench. The drill guide makes it easy to start the hole without worrying about the drill bit slip ping and marring your project. and it also guarantees that your holes will be straight.

EDGE DRILLING. A drill guide can also be used to center holes on the edge of a workpiece. As you can see in the photo below, a wide, shallow notch is cast into the base of the guide. Rotating the base until the corners of the notch contact the sides of the workpiece automatically centers the drill bit on the edge. This is useful for drilling out mortises or drilling holes for dowel joints.

ROUND STOCK. Another feature common to most drill guides is a V-notch, also cast in the base. This allows you to drill centered crossholes in dowels or pipe, as shown in the photo below.

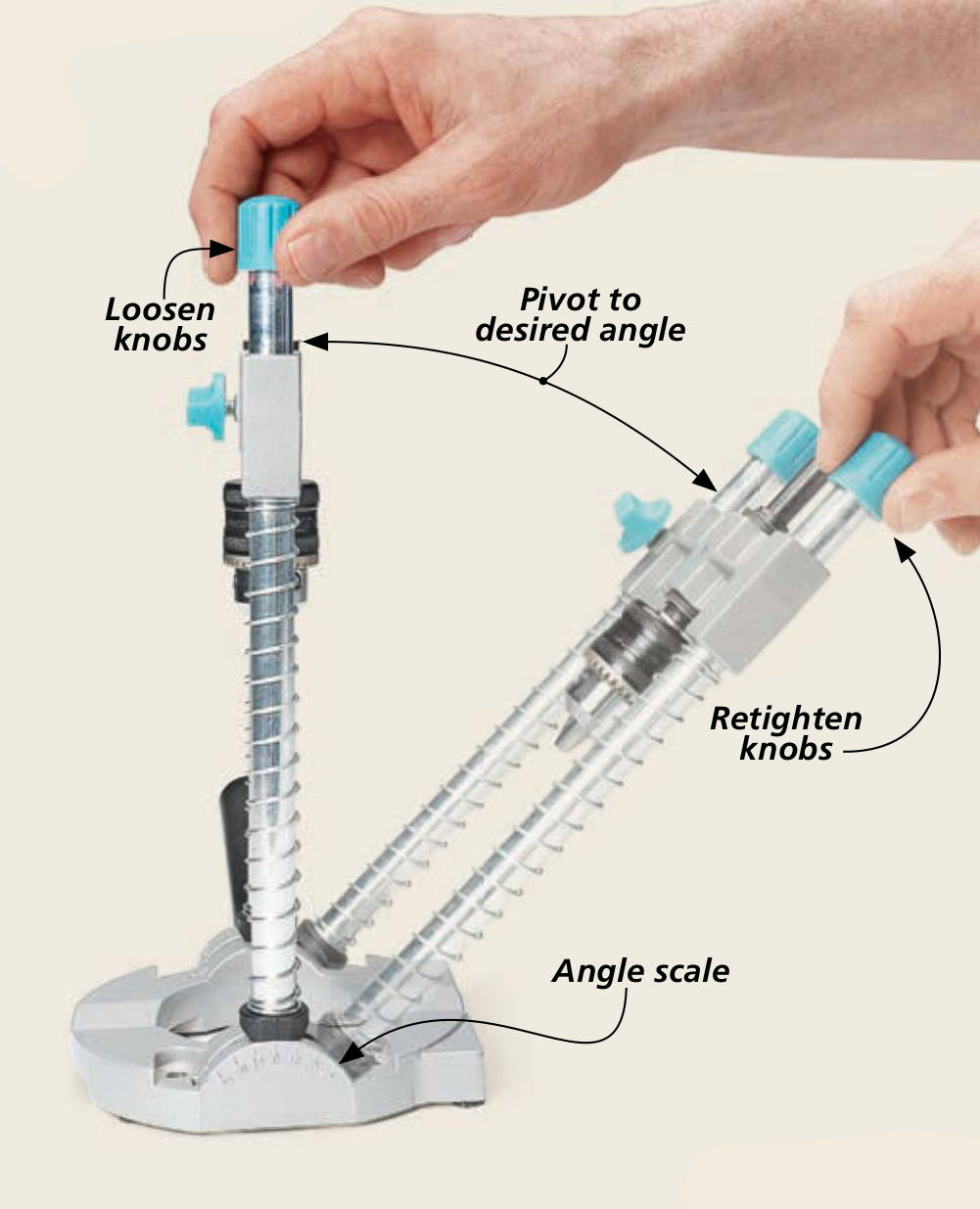

ANGLED HOLES. Drilling angled holes is always a bit of a challenge, even on a drill press. Trying to hold the workpiece steady on the tilted table of the drill press is difficult at best. But the Wolfcraft guide makes drilling angled holes quite simple.

As you can see in the second photo below, the base pivots on the end of the guide rods. All you have to do is loosen the knobs at the top end of the rods and pivot the base to the proper angle. A scale cast into the base helps you with setting the angle. Since the guide holds the drill at the desired angle, your workpiece remains flat on the workbench.

If you don’t own a drill press, the Wolfcraft drill guide is the next best thing. But even if you have a drill press, I’m willing to bet that you’ll find plenty of uses for this jig. It’s the kind of tool that doesn’t take up much space or cost a lot of money, but can be a real lifesaver when the occasion calls for it. It's definitely a tool worth having in your shop.