Ted Raife, a former editor here at Woodsmith, used to say that woodworking is nothing more than "Cutting big pieces of wood into small pieces, then joining them back into larger pieces."

It's a clever turn of phrase. But we can also use it as a starting point for exploring how to do woodworking tasks. Over a series of posts, I'll share what this looks like in my home shop (as opposed to what you see on the TV show).

The first part of the definition "Cutting big pieces of wood into smaller pieces ..." is where I'll start.

These photos show the three saws that touch wood first when it comes into my shop.

After unloading long boards from my car, I grab my vintage Disston crosscut saw to break them up into rough-length parts. At the lumberyard, I typically mark the boards with chalk to know what pieces parts they'll get turned into.

After unloading long boards from my car, I grab my vintage Disston crosscut saw to break them up into rough-length parts. At the lumberyard, I typically mark the boards with chalk to know what pieces parts they'll get turned into.

Cutting perfectly square isn't necessary here, but I try to mark clear lines and follow them as closely as possible. This hand-eye training develops my sawing skills that get put to use later on the in the project.

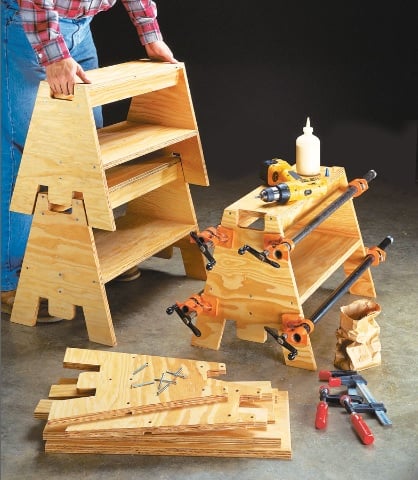

The boards are placed on a pair of low sawhorses The design comes from ShopNotes and came out years before the recent revival of saw benches. Even though they're made from plywood, they work great as saw benches in my shop.

I used the plastic handled saw in the background before getting the Disston. I still use it on green wood ... and even for general yard work. The impulse-hardened teeth cut through all kinds of materials: tree limbs, PVC pipe and exterior trim, plywood, drywall ...

For plywood and MDF, I use the Porter Cable Sawboss circular saw I picked up pre-owned. I always loved Norm's little PC-314 saw he used for cutting sheet stock on the New Yankee Workshop. Sadly, I was never able to find one.

For plywood and MDF, I use the Porter Cable Sawboss circular saw I picked up pre-owned. I always loved Norm's little PC-314 saw he used for cutting sheet stock on the New Yankee Workshop. Sadly, I was never able to find one.

This one isn't as small, but the 6" blade makes for a nimble tool. I have a 40-tooth blade that leaves finish-quality cuts so I can cut plywood pieces to size right from the sheet.

A hand saw and a small circ saw transform large boards and sheets into pieces I can more easily manage in my shop.

Next time, we'll look at the saws that do more precision work. — Phil Huber