Subscribe Today

Subscribe Today

Subscribe to Woodsmith magazine

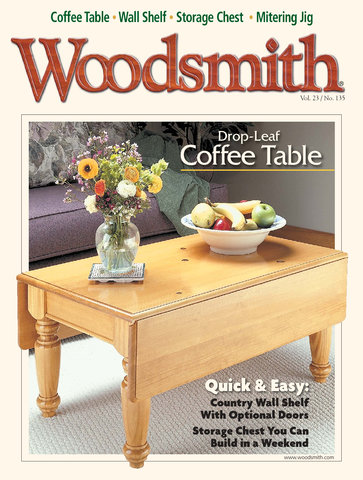

With its turned legs and drop-leaf tabletop, you may be surprised to find that this project can be built in just a few days. The secret? A simple design and some ready-made legs. (Plus, we've included a matching sofa table on page 10.)

READY-MADE LEGS. We purchased our turned legs from Grand River Wood Products. The style we used is “Butcher Block Pine.” Other leg styles in different types of wood are available from some of the sources in the margin.

A drop leaf is a great way to extend a tabletop. And making it isn't as complicated as you might think. All you need are a couple of common router bits and a special hinge.

To give this wall shelf a country look, we used knotty pine, simple construction, and a beaded-board back. And if you want an attractive display cabinet, there are optional doors you can add to the shelf. Either way, it's a quick, easy-to-build project.

Gluing up a project may be the most nerve-racking part of woodworking. Once the glue is on, you only have minutes to get things together -- and get it together right. These tips from our shop will help things go smoothly, no matter what the assembly.

Lift the lid of this chest and you'll find plenty of room for storage. What you won't find is any hint that it's built from plywood and ready-made moldings. Just one trip to the home center will get you everything that's needed to build this handsome chest.

You can probably pick up all the materials needed for the storage chest on page 26 at your local home center. The only hardware needed is a few screws and brads, a pair of no-mortise hinges, and a length of chain to keep the lid from falling back. If you can’t find the hinges, check with the sources at right. The molding used on the faces is door casing. Different lumber yards may carry different profiles, so look around until you find one you like.

BUN FEET. The bun feet can be ordered pre-made, or you can turn them yourself. The feet we used came from Grand River. They’re only available in ash, but ash is a close match to oak, which is what we used to build the chest.

FINISH. Getting just the right color for the chest was a challenge, to say the least. I ended up mixing together four stains from General Finishes for the first coat. This consisted of three parts of Red Mahogany, two parts of Walnut, and one part each of Honey Maple and Antique Cherry. After this had dried, I brushed on a second coat of just the Red Mahogany. For the top coat, I wiped on three coats of Hope’s tung oil varnish.