Subscribe Today

Subscribe Today

Subscribe to Woodsmith magazine

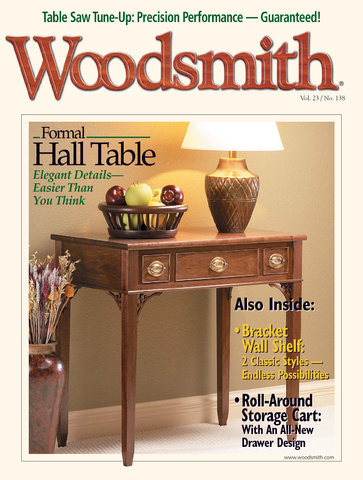

This elegant project offers plenty of woodworking challenges -- long tapered legs, optional scroll sawn corner brackets, beading around the drawers, and solid walnut construction.

The hall table on page 6 doesn’t require much hardware. Besides a few screws, the only hardware you’ll need is three bail pulls with mounting bolts. The ones I used are a 2" Hepplewhite style (see photo at right). Mine were ordered from VanDyke’s Restorers (#CH-02299842). Similar pulls can be found from several other of the mail order sources listed.

JIG. The jig needed to cut the tapers on the legs is pretty basic (page 17). The only hardware that may not be readily available is the star knobs used on the hold-downs. These knobs can be purchased from several of the sources listed in the margin.

FINISH. When it came time to apply a finish to the table, I wanted to let the natural beauty of the walnut shine through. Walnut is already very dark, so stain isn’t needed. The dark color needs only a clear finish to enhance it. Two coats of a tung oil varnish provided a nice sheen and some protection for the table top.

A unique open design makes this more than just a utility cart. The contrast between the cherry and maple pieces makes it a handsome addition to any room. And look closely -- those cherry pieces on the side are actually the drawer runners.

For the roll-around cart on page 18, the only hardware you’ll need is some screws and a set of casters. The ones I used were a twin wheel caster made of nylon. I chose them because they have a hood over the exposed portion of the wheels which gives them a more finished look.

If you plan on using the top of the cart for a work surface (or just don’t want the kids pushing the cart around), you may want to consider a locking caster. While I used just a regular caster, the same type of caster can be purchased with a built-in brake. This allows you to lock the wheels to keep the cart in place.

You can probably find 2" casters at most home centers, but they are also available from several of the sources listed in the margin.

FINISH. I usually don’t stain cherry. I’ll just wipe on a top coat and then let nature take its course. The color of the wood will deepen naturally as it’s exposed to light. But if you use a different type of wood, you may want to stain it. If so, it’s much easier to stain the drawer runners before you attach them to the case. And remember to mask off surfaces that will be receiving glue.

Think you should be getting better results from your table saw? Follow these simple tips, and you should notice real improvement in your saw's performance. Best of all, you can do a tune-up in less than an afternoon -- and you don't need any special tools.

Taking the time to maintain your table saw as described on page 26 can make time spent in the shop much more enjoyable. You may already have some of the products needed for a “tune-up” in your shop. If not, they can be found at local hardware stores or home centers. But if there’s an item you can’t find locally, check with the mail order sources listed.

Two shelves. Two different styles. But both versions are built with the same basic procedures. And it's easy to make either shelf whatever length you need to fit the space on your wall.

Finish information: The shelf was stained with a blend of 1 pint General Finishes Special Walnut and 2 pints General Finishes Golden Oak.

A simple groove makes it easy to position this jig perfectly every time you rout a dado. An adjustable stop sets the length for stopped dadoes. Or remove the stop and use the jig as a straightedge for routing dadoes all the way across a panel.