Subscribe Today

Subscribe Today

Subscribe to Woodsmith magazine

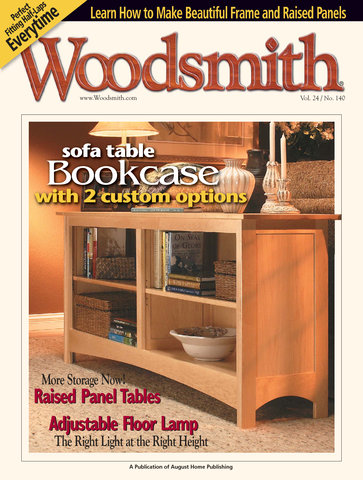

Featuring solid-wood construction and a distinctive design, this long, low bookcase will fit great behind a sofa. Of course, once you see it with some optional doors, you'll realize this project could go just about anywhere.

There's not a lot of hardware needed for the sofa table bookcase on page 6. In fact, if you’re building the open version (without doors) then all you need are a few woodscrews, washers, and some 1/4"-dia. shelf pins.

HINGES & PULLS. But if you're building the doors, then there are some additional items you'll have to get ahold of. First I chose some small satin-nickel pulls (BWP7523) from Woodworkers Hardware (see list below).

Next, you’ll need 3/8" inset, freeswinging hinges (AO7697 3 from Woodworker's Hardware). This type of hinge will be readily available from a hardware store or home center (or the sources below), but don’t be surprised if you can’t find any with a nickel finish. I ended up buying brass hinges, and then after a light sanding with 400-grit sandpaper, I simply spray painted them silver.

The only other hardware item you'll need for the doors are magnetic catches. I used common surface-mounted catches (and strike plates).

However, you might also want to take a look at the cherry version that's shown on our web site (see the Online Extras for this project.) It features Craftsman-style pulls that are available from the sources listed below. (The hinges would also need to be painted black.)

REEDED GLASS. For the doors with glass panels, I went to a local glass shop and purchased 3/16" reeded-glass panels. (You'll want to do this after the doors have been assembled so you can give them the exact size of the rabbeted frame openings.) And whether you decide to use reeded glass or standard 1/8" glass, I'd recommend that you order safety glass.

FINISH. Since very little plywood was used on this project, the color of the wood was pretty consistent, so I didn't feel that the wood needed to be stained. Instead, I simply wiped on several coats of a tung-oil varnish.

Frame and raised panel construction is one of the hallmarks of fine cabinet-making. And with two shop-tested methods for making the raised panels, you'll be turning out perfect frame and panel assemblies in no time.

The raised-panel storage tables don’t require any special hardware. And if you like the look of a flat-beveled raised panel, you can cut them on the table saw. But curved-profile raised panels can also be built in your shop. All you need is a router table and a vertical raised-panel bit. The one shown on page 19 is made by Amana (54520) and can be ordered from the mail-order sources below.

This one-of-a-kind floor lamp can be adjusted by loosening a small wood knob and raising or lowering its center column. It's a unique feature that doesn't require any tricky joinery or special hardware.

When building the lamp on page 22, you won't need much hardware at all. Besides a handful of woodworking screws, all you need is a 1/4"-20 brass insert, a 1"-dia. cherry wood knob (61665 from Rockler), and a short length of threaded rod. All of these items should be available at a home center or a woodworking store, or the insert and wood knob can be ordered through the sources listed below.

The electrical supplies are also available locally at hardware stores and lamp shops. In fact it's often packaged as a complete kit. However, there are additional sources listed at right that offer lamp supplies.

Wiring a lamp is pretty basic, and the instructions should be included in your hardware kit. Still, if you have any reservations or questions, don't hesitate to find someone who can guide you through the process.

Half laps are strong, quick, and versatile. In short, they're a great way to join two pieces or build a frame. Here, we'll walk you through the process from setup to assembly.

With solid-wood frame and panel assemblies on all four sides, this accent table looks good from any angle. And under the lift-off lid, you'll find lots of practical storage space.