Table of Contents

Tips & Techniques4

Bench Dogs & Hold-Downs8

Securing your work is essential. We'll take a look at the old standbys and the latest innovations.

Sources

To get the most out of your workbench, you’ll want to add a few handy

devices to help hold your work securely in place. The bench dogs and

hold-downs in the article on page 8 are just a sampling of the variety

available. The Veritas line of bench accessories is sold by

Lee Valley. You can find the other items shown at

Rockler. Contact information for both is listed below.

One-Hand Clamps10

You'll see why these versatile clamps deserve a spot in every woodworking shop.

Sources

One-hand clamps, like the ones shown on page 10, can make glueups and lots

of other workshop tasks simpler. To find the clamp that fits your needs,

check out the websites for Amazon.com, Woodcraft,

and Rockler.

JIG-IT Hinge Mortiser12

With this versatile, inexpensive jig, routing perfectly sized hinge mortises is a sure thing.

Sources

The JIG-IT Mortising System shown on page 12 makes short work

out of adding hinges to a project. The JIG-IT system (32457)

is available from Rockler and the Woodsmith

Store.

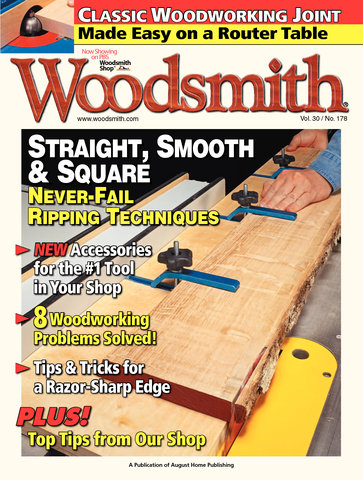

Straight Lumber14

We'll show you some tips and tricks to get your project started on the right foot.

Sources

You can save a lot of money by passing up the S4S section of the lumber

yard and building your projects with rough lumber. And the techniques in

the article on page 14 will get you pointed in the right direction. To

build the jig for cutting a straight edge, you’ll need a few

supplies. The mini T-track (36033)

and star knob hold-down clamps (21912)

both came from Rockler. The E-Z Jointer Clamp Kit

shown in the article is from General Tools (846).

Magazine Rack16

It isn't every weekend that you can lay claim to a project that's this practical and looks this good. Straightforward joinery and some hardware helpers make it all go together in a snap.

Updates

- Page 19: Template for Upper Rail & Handle

Two measurements on the template require correction: 1. The measurements out from the centerline should be 1 3/4", not 2" as originally printed. 2. The holes to be drilled for the handle should be 7/8" diameter, not 1" as originally printed. The template should still be enlarged to 200%.

- Page 17: Materials, Supplies & Cutting Diagram

Two corrections: (1) The bottom blank, from which 18 slats for parts F and K are cut should be 4 1/2" wide, not 3 1/2" as originally printed. This would change the parenthetical comment as well. It should read 2.3 sq. ft., not 1.8 bd. ft. (2) Part J (Lower Side Rails) should be 15 1/2" long, not 15" as originally printed. The measurement is shown correctly in the drawings.

- Page 17: Exploded view illustration

The roundover on the side stops should be 1/8". It's described correctly on page 20.

- Page 20: Detail b, top view

The measurement from the edge of the bottom rail to the edge of the side stop should be 7/8", not 3/4" as originally printed.

Sources

The magazine rack on page 16 is a great way to keep track of your reading

material. And it doesn’t require a lot of time to build. The antique

copper continuous hinge (35256)

and the heavy-duty, twinwheel casters (90365)

came from Rockler. The connector screws (1420-CWB)

are from McFeely’s.

Lighted Display Cabinet22

Building an attractive display cabinet doesn't have to be a lot of work. This project proves the point. Clean lines and simple construction create the perfect place to show off your treasures.

Updates

- Page 26: Illustration

The glass door panels should be 18-7/16" long; not 18-7/8" as shown in the drawing at the top of the page. The dimension of the glass door panels in the materials list is accurate. Corrections to the glass panel size are based on the assumption that the rabbet for the panels is 3/8" wide. This measurement is not found on the drawing or detail that shows this but based on the size of the glass stop, 3/8" is appropriate.

- Page 25: Case and Base Assembly

Clarifications (1) Neither the art nor the copy mention the offset of the legs and rails when the pieces are assembled. That offset is 1/4". (2) The location of the case on the base assembly needs further explanation. The case of the project is centered on the Base Top (G) and screwed in place. This places the case in the same plane as the outer faces of the legs.

Sources

You’ll need a few pieces of hardware to complete the display cabinet

on page 22. The low-profile pocket lights (39705)

are from Rockler, and the door knobs and escutcheons (01A23.76)

are from Lee Valley. The ¼″-thick beveled glass

(with a 1″ bevel) used for the doors was obtained from a local glass

supplier. The mixture of equal parts Java and Georgian

Cherry gel stain from General Finishes makes the poplar

look like walnut. Sprayed lacquer completes the finish.

Shop Notebook28

Traditional Swing-Leg Table30

I think you'll agree, this is no run-of-the-mill table project. Its unique function and woodworking challenges are guaranteed to give you a double dose of woodworking satisfaction.

Updates

- Page 51: Swing Leg Table Finish Source

The finish used was cherry Jel'd Stain from WoodKote. The sources page reads "Gel'd stain from Wood Cote." It is available from www.woodkote.com, 800-843-7666.

- Page 51: Table Legs

As of 2013, the Sheraton-style table leg part number 303KD-CH and the Shaker-style leg part number is 202KL-CH. Note, both are now 2 1/4" square; the old parts were 2 1/8" square. This affects another part: Support Blocks (F). See the other correction note for details.

- Page 33: Measurements affected by leg size

The dimensions of the new table legs differs from those used in the original article (from 2 1/8" to 2 1/4" square), several other measurements may be are affected. Support Block (F) should be 1 1/4" thick. If you follow the procedure as written and use the dimensions list for the leg mortises, the outer side rail sizes will automatically adjust to accommodate the new leg size. The following changes may also be made: On page 33, in the How-To Box, the three 2 1/8" dimensions should be 2 1/4". On page 34, the measurement in the lower part of detail d and in the seventh paragraph of text should be 18 1/4". One page 38, Material, Supplies & Cutting Diagram, change the Legs (A) from 2 1/8" x 2 1/8" to 2 1/4" x 2 1/4". Change Support Blocks (F) thickness from 1 1/8" to 1 1/4".

Sources

The swing-leg table featured on page 30 offers a versatile design. You don't need to worry about not having a lathe or a lack of turning skills either. We ordered the Sheraton-style legs (303KD-CH)

and the Shaker legs used in the Designer's Notebook variation (202KL-CH)

from Classic Designs by Matthew Burak. They also sell turning

blanks so you can make your own legs. The drop-leaf hinges (29256)

are from Rockler. The finish we used is cherry

Jel'd Stain from WoodKote.

Routing a Rule Joint40

A few minutes at the router table is all it takes to create this traditional drop-leaf joint.

Razor-Sharp Edge42

Don't rely on myth. Here’s what you really need to know about sharpening edge tools.

Custom-Mixed Stains44

When you want the perfect stain color, your best bet might be the one you mix yourself.

Updates

- Page 45: Color Mix Ratios Chart

The measurement for the stain that appears third from the bottom should be in the brown column, not the yellow column.

Sources

You can give your projects a unique look with colored stains. The article

on page 44 will help you get started. The Winsor & Newton Winton

Oil Colour paints are sold at most art supply stores. For butcher

block oil and boiled linseed oil, check your local hardware store or home

center.

Managing Wood Movement46

Wood movement is a fact of life. But there are many tried-and-true ways to deal with it.

Q & A50

Final Details52