Subscribe Today

Subscribe Today

Subscribe to Woodsmith magazine

There's a type of glue for every woodworking task. Here's what you need to know.

You shouldn't have much trouble finding any of the glues discussed in the article on page 8. Just pay a visit to your local hardware store or home center. If you do have a problem locating a particular type, try the Woodsmith Store.

We'll take a look at a new, innovative option in router bits offered by Amana.

Replaceable insert router bits, like Amana’s new In-Tech line, might be the wave of the future. To be on the cutting edge, so to speak, go to Amana’s web site to locate a dealer near you.

Learn a great table saw technique that results in strong, easy-to-assemble mitered frames.

Turn your bench grinder into a precision sharpening station by upgrading the tool rest.

If you’re sold on the benefits of upgrading the tool rest on your bench grinder, you can’t go wrong with either option shown in the article on page 14. The Wolverine Grinding Jig is available from either Woodcraft (125676) or Rockler (24707). The Veritas Grinding Jig (05D13.02) comes from Lee Valley.

Another way to get better results from your bench grinder is to install a fast-cutting aluminum-oxide grinding wheel. You can purchase 6″- or 8″-dia. wheels in several grits from Rockler.

This project proves that a small clock can still have "grandfather" details. You'll be in and out of the shop in a weekend, but your clock will be treasured for a lifetime.

Before starting on the mantel clock on page 16, I ordered the movement and a few other necessary items from Klockit. Here’s what you’ll need: a six-melody quartz chime movement (12161), a white Roman numeral clock face (26618), a set of hands (66992), a package of turnbuttons (39957), a 3/8″-dia. brass knob (39051), a pair of brass hinges (39212), and a magnetic catch (39011).

To finish the clock I used our favorite custom stain mix — 3 parts Zar Cherry Stain to 1 part Jel’d Cherry Stain. This gives the desk clock its warm, aged look.

This project certainly doesn't have the look of your run-of-the-mill bookrack. The light, open design makes for great "anywhere" storage and some challenging woodworking.

You only need a couple of special hardware items to build the bookrack. The bottom shelf is attached with tabletop fasteners from Rockler (34215). I bought a section of steel rod at the hardware store to make the trough supports.

The bookcase was finished “naturally” with several coats of wiping varnish. This simple finish gives the wood a pleasing amber glow.

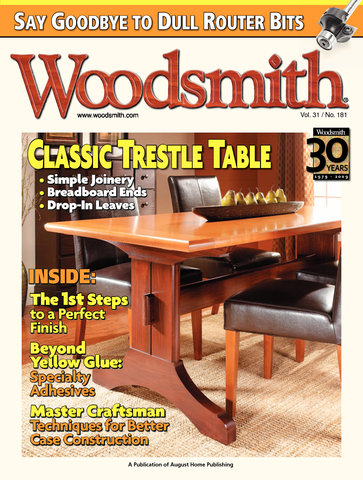

The trestle-style dining table brings together the old and the new in a great project. The design is classic, while the construction and the expandable feature are more up to date.

Much of the hardware you’ll need to build the trestle table can be found at a hardware store. But you’ll have to order a couple of items. The table leaf fasteners (00S10.21) and the table alignment pins (00S10.04) can be purchased from Lee Valley.

The finish on the trestle table requires two stains. The dark poplar base is stained with General Finishes Java Gel Stain. The cherry top was stained with our favorite custom mix — 3 parts Zar Cherry Stain to 1 part Jel’d Cherry Stain.

A shop project should be practical. But that doesn't mean you can't show off your woodworking skills. Building this traditional handsaw till will give you the best of both.

With a handful of basic tools and a time-tested technique, you can cut first-class dadoes.

There are a couple of nice hand tools shown in the article on page 44 that may have piqued your interest. The back saw shown in the main photo is the small tenon saw offered by Adria. The Veritas router plane pictured on page 45 is available from Lee Valley. Lie-Nielsen makes a similar saw and router plane.

When it's time for a finish, this four-step process guarantees you start off on the right foot.

Dovetails aren't just for drawers. Find out how to put case dovetails to work in your projects.