Subscribe Today

Subscribe Today

Subscribe to Woodsmith magazine

There's more to choosing the right sandpaper than you might think. Here’s how to get it right.

You can find a wide variety of sandpaper at just about any hardware store or home center, as well as the woodworking suppliers listed in the margin at right. For wet/dry, silicon carbide sandpaper, automotive supply stores are often a good source.

Get the scoop on finding a stack dado blade that will give you the most bang for your buck.

A stack dado blade is certainly one of the best investments you can make for your table saw. Several blade manufacturers (Freud, Forrest, and Infinity Tools) make high-quality stack dado sets for around $200-$250. If you’re looking for a good, "entry-level" dado blade, the Freud Pro Dado (SD208) is an excellent value. It typically sells for about $100.

Here's a handy set-up gauge that puts machine shop accuracy at your fingertips.

The Multi-Gauge is available directly from Oneway Manufacturing, or from several of the sources listed below.

This modern joinery technique can make your projects go together faster and better.

When it comes to pocket hole jigs, the Kreg Tool Company wrote the book. You can purchase Kreg jigs through most woodworking dealers. Or view all the products Kreg has to offer by taking a look at their website, kregtool.com.

There's no stitching required -- just a couple days of straightforward woodworking. The end result is a unique project that's guaranteed to attract attention and compliments.

Aside from the wood, the only thing you'll need to complete the quilt-top boxes on page 18 is some adhesive-backed felt. You can find this at most craft stores.

To finish the boxes, I simply applied a coat of General Finishes' Seal-A-Cell, followed by a couple coats of spray lacquer.

Who says that straightforward construction and style can’t go hand in hand? Here’s proof positive. No-nonsense techniques and simple details add up to a practical, great-looking project.

In addition to pocket screws, there are a few other items to purchase for the knock-down bookcase on page 24. The connector bolts (00N14.30), cap nuts (00N20.17), leveler brackets (01S04.01) and leveler feet (01S06.02) were all ordered through Lee Valley. For the 1/4"-thick fluted glass panels, we went to a local glass shop.

To give the red oak a little warmer color, the bookcase was finished with a coat of General Finishes' Seal-A-Cell and then two coats of lacquer.

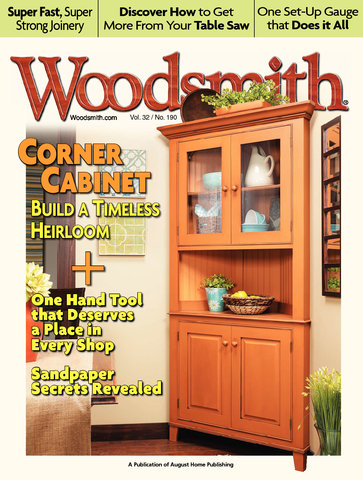

This handsome corner cabinet gets all the traditional details right -- from its crown molding and beaded back to its painted finish. The bonus is making good use of an empty corner.

To build the corner cabinet on page 32, you'll need magnetic catches (26559), a leg leveler (31210), and figure-8 fasteners (21650) from Rockler. For the door hinges (CP-11), shelf pins (SP-10), and Shaker knobs (WK-7), we turned to Horton Brasses.

We also used several router bits to create the various moldings for this project. The ogee bit (54120) and the reed bit (54360) are both made by Amana Tool.

The crown molding (F610) was manufactured by Ferche.

When it came to selecting a paint color, we chose two different shades. The beaded plywood back of the cabinet is painted with Benjamin Moore's Peach Brandy. The color of the rest of the cabinet is cite>Masada. Then to give the cabinet an aged look, we applied a coat of General Finishes' Gel Stain (Java) as a glaze.

Learn a few simple techniques that will allow you to get more from this essential hand tool.

We'll show you how to make your project shine with this tried-and-true finishing technique.

To create a traditional handrubbed finish, you’ll need a number of supplies. These include varnish (or lacquer), paste wood filler, pumice, rottenstone, paraffin oil, felt blocks, and non-woven abrasive pads. You can find most of these finishing supplies from one of the several sources listed below.

Using a combination of power and hand tools, you can make classic-looking door frames.