Tips & Techniques4

Six tips from fellow woodworkers: 1) Jig for Cutting Thin Strips. 2) Right Hand Router Rules. 3) Pipe Clamp Extender. 4) Table Top for Roller Stand. 5) See-Thru Clamping Block. 6) Starting Screws in Tight Places.

Subscribe Today

Subscribe to Woodsmith magazine

Six tips from fellow woodworkers: 1) Jig for Cutting Thin Strips. 2) Right Hand Router Rules. 3) Pipe Clamp Extender. 4) Table Top for Roller Stand. 5) See-Thru Clamping Block. 6) Starting Screws in Tight Places.

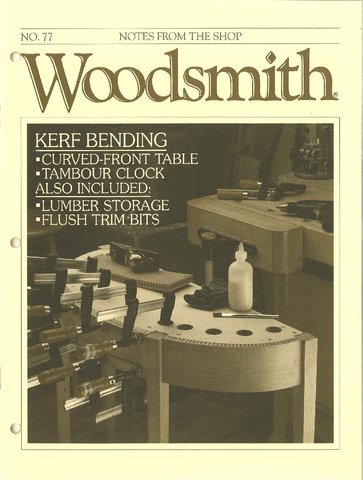

The curved top of this traditional Tambour Clock was made by gluing veneer over kerf-bent Masonite. A timely technique for a timeless design.

The key to successful kerf bending is the spacing between the kerfs and cutting the kerfs to the right depth. Use this technique to create classic designs.

1) Drawing a Partial Ellipse. 2) Resawing Face Veneer from Plywood. 3) Routing with a Pilot Strip. 4) Rabbeting without Chipout

We made the "inlaid" legs on this table without doing any inlay. And the curved aprons are kerf-bent plywood. A classic project, but modern techniques.

1) Positioning a Guide Block to Resaw on the Band Saw. 2) Storing Small Amounts of Lumber. 3) Using Slow-Setting Glue. 4) Table Saw -- Working on the Left Side or Right Side of the Blade?

Winners of the wood storage contest. A two-part system for storing lumber and plywood. A fold-down plywood wall rack. Using bungee cords -- and also spring poles -- to keep your lumber neatly and securely in place.

Two flush trim router bits. With the pilot bearing on the top or the bottom, routing a pattern is fast and accurate.