Tips & Techniques4

Five great tips. 1) Drilling Out Mortises. 2) Carriage for Bevels. 3) Dimpled Splines. 4) Router Table Push Block. 5) Containers for Mixing.

Subscribe Today

Subscribe to Woodsmith magazine

Five great tips. 1) Drilling Out Mortises. 2) Carriage for Bevels. 3) Dimpled Splines. 4) Router Table Push Block. 5) Containers for Mixing.

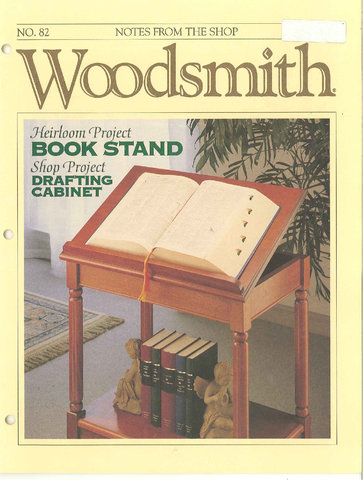

The legs are made on a lathe in short, easy-to-turn sections. And the top lies flat or tilts -- thanks to a shop-made ratchet system.

The Book Stand can also be built with square legs. No lathe needed.

This fence can be made to fit any band saw table. A sliding wedge system allows precise adjustments.

1) A Template for Turning Spindles. 2) Band Saw "Drift." 3) Drilling into the End of Long Stock. 4) Enlarging a Round Tenon. 5) Checking for Square.

The results are in for our Shop Tips Contest. The winners: A Circular Saw Edge Guide, T-Square Router Guide, and an A-Frame Support.

Answers to questions from readers. 1) Avoiding Blotchy Stain. 2) Steamed Cherry. 3) Saw Blade Selection. 4) Tempered Hardboard.

The front of this cabinet pivots down on steel pins to a comfortable height for drawing.

What goes into the design of a Woodsmith project? Here's a look at the evolution of the Drafting Cabinet.