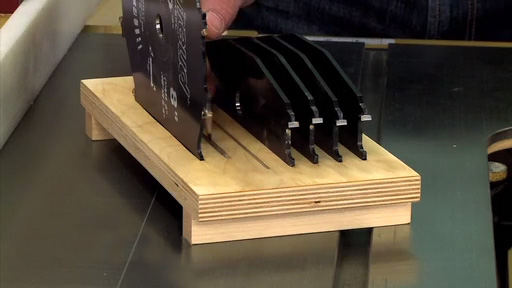

Cutting small, curved parts can be a challenge if you don’t own a band saw. A jig saw will work, but trying to hold a small piece while cutting it can be dangerous and usually produces poor results. To get around this problem, I built this jig saw table. It allows you to use both hands to guide the workpiece. The design makes installing the saw a breeze.

You’ll find it works best to use a fine-tooth blade to keep the workpiece from jumping around. You may want to tape very small pieces to a carrier board for easier control. And cut with the workpiece face up to minimize chipout on the finished side.

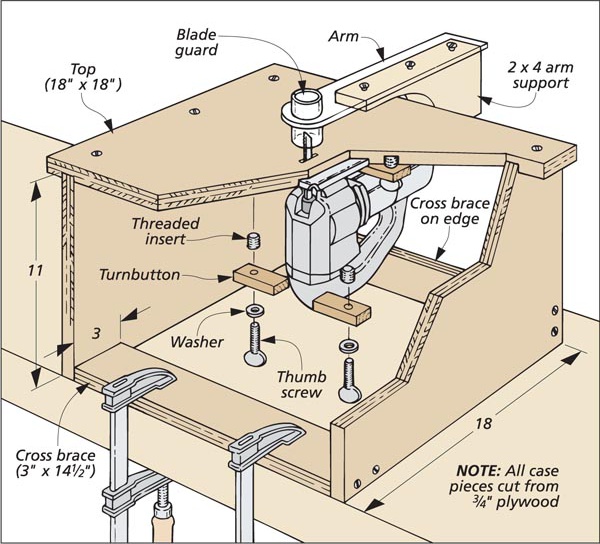

Making the table is pretty straightforward, too. It consists of a plywood top, two sides, and a pair of cross braces.

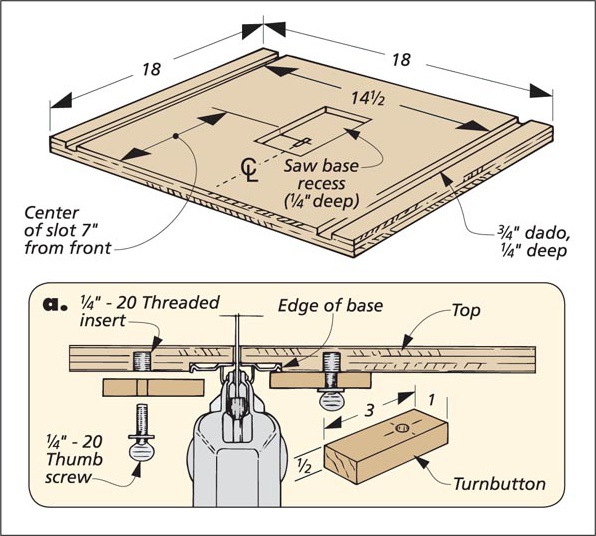

Before assembling the table, you’ll need to rout a shallow recess in the top for the saw’s baseplate. Then just cut a thin slot for the blade. Now you can cut the dadoes for the sides.

The sides are fastened to the top with screws. A pair of cross braces are attached to the sides on the bottom and along the back edge. These prevent the table from racking and allow the table to be clamped to a workbench. The jig saw can be secured with four hardwood turnbuttons. Thumb screws and threaded inserts hold the turnbuttons tight.

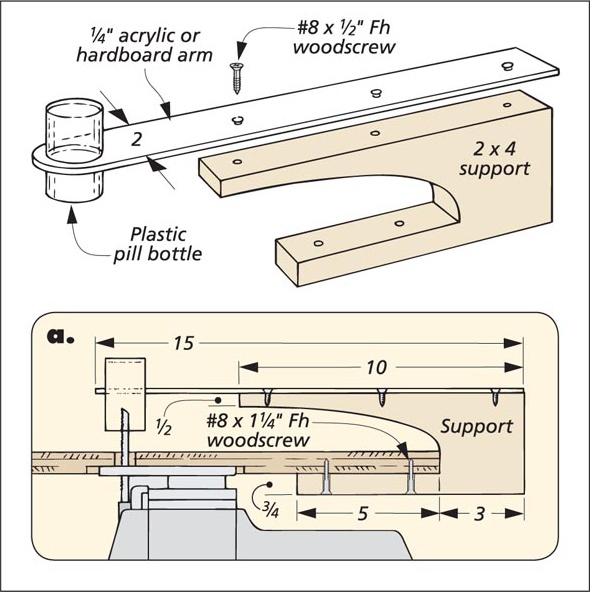

The next step is to cut out the support for the blade guard. For this, I used a short piece of 2 x 4. I used a piece of clear acrylic for the arm, but you could also use 1/4" hardboard. Then you can drill a hole for the guard. An old plastic pill bottle works great here, so just drill the hole to fit the bottle you choose. A couple drops of cyanoacrylate glue hold it in place.