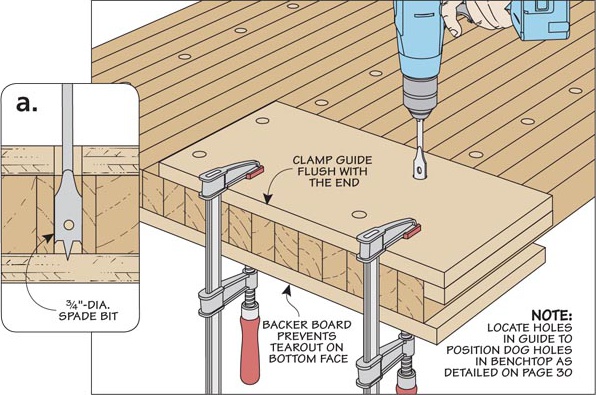

A row or two of 3/4"-dia. bench dog holes allows you to add all kinds of stops, clamps, and vises to your worksurface. While you can simply drill a hole anywhere, I like to space them consistently across the length of the bench.

Using a jig you see here does the trick. Another advantage is that the thick plywood guides help you keep the bit perpendicular to the surface.

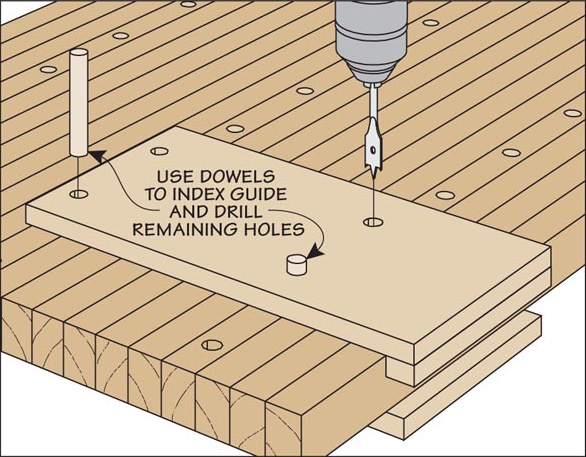

The guide is just a piece of plywood with two sets of guide holes. I drilled these at the drill press to make sure they’d be square. A cleat on one edge of the guide registers it against the side of the benchtop. I used a couple of clamps to prevent the guide from shifting during use. And I placed another piece of plywood on the bottom face of the benchtop to prevent tearout as the bit exits. To accurately position the guide after drilling the first set of holes, slip a couple of dowels through the guide.