I make it a point to periodically give my router a quick “once over.” It only takes a few minutes and easily pays for itself in less wasted time and aggravation. First, I turn my attention to the inside of the router base and the motor housing that slides into it. The problem is that after countless bit changes, height adjustments, and the cuts that follow, these two parts get roughed up and covered with grime. Once this happens, you can forget about making the quick, accurate height adjustments that you rely on. But solving this problem is pretty simple. First, take some fine sandpaper or an abrasive pad and use it to remove the accumulated grime, scratches, and burrs from the motor housing. Next, do the same to the inside of the base. A small wire brush will get into the grooves in the base that can get caked with dust. And after wiping down the motor and base, a light coat of spray lubricant completes the job.

Although a router motor is designed to stand up to hard use and dirty conditions, there are a couple of routine things you can do to keep it and all the other electrical parts in top shape. Dust is the number one enemy here. It’s constantly being sucked through the motor and settling in every nook and cranny. So the goal is to prevent excessive wear by keeping the inside of the motor as clean as possible. The photo shows how easy this is. After removing the motor cover, a sharp blast of compressed air will dislodge most of the dust. The switch and other electrical connections need attention as well.

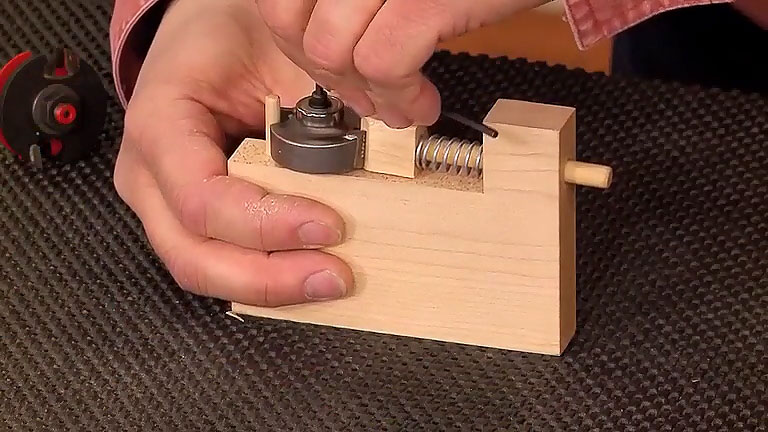

The final stop is the business end of the router — the collet that holds the bit. The goal here is to make certain the collet gets a guaranteed, rock-solid grip on the bit while also allowing hassle-free bit changes. First, I work on the shank hole in the collet. It should be smooth and clean.

Next, you want to make sure the collet seats properly by cleaning the debris out the arbor socket.

Finally, I lubricate the threads so that the collet nut can be tightened and loosened easily.