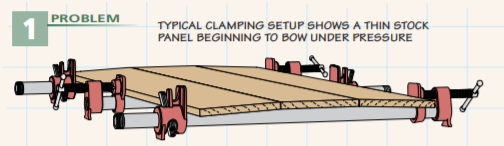

Figure 1 shows some problems you might deal with when clamping thin stock using bar or pipe clamps. The narrow edges of thin thin boards are prone to buckling when clamping pressure is applied. This can leave you with a cupped panel that's nearly impossible to flatten.

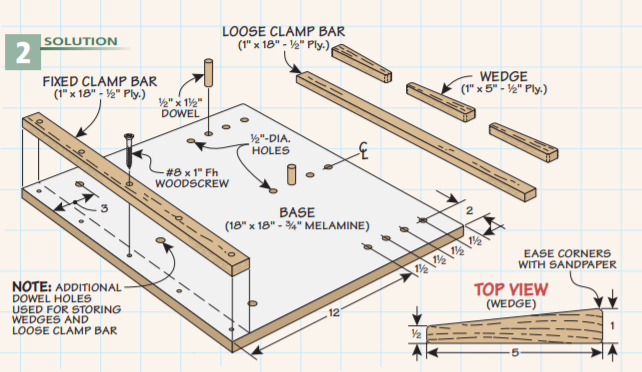

Plus, the clamps can easily dent and mar the thin edges. So instead, I skip the clamps and turn to an assembly jig like you see in Figure 2.

Clamping pressure is supplied by a set of wedges that bear against dowels and a pair of clamping bars. One bar is screwed to a melamine base. The melamine keeps the panel from being glued to the jig. The other clamping bar, along with the dowels and wedges, are adjustable using a set of evenly spaced holes in the base.