After years of making throw away push blocks for my table saw, I decided I wanted to make a forever push block. It needed to be more stable while in use, and have a replacable base once it gets chewed up. The design I came up with has components that do that and is adjustable for different thicknesses of stock.

After years of making throw away push blocks for my table saw, I decided I wanted to make a forever push block. It needed to be more stable while in use, and have a replacable base once it gets chewed up. The design I came up with has components that do that and is adjustable for different thicknesses of stock.

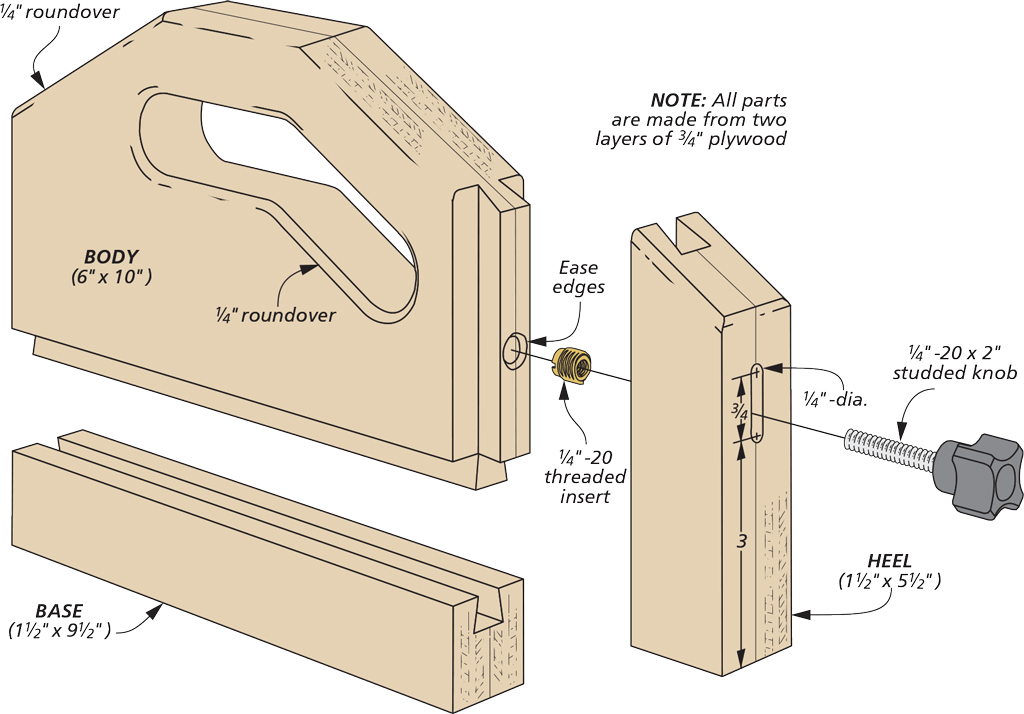

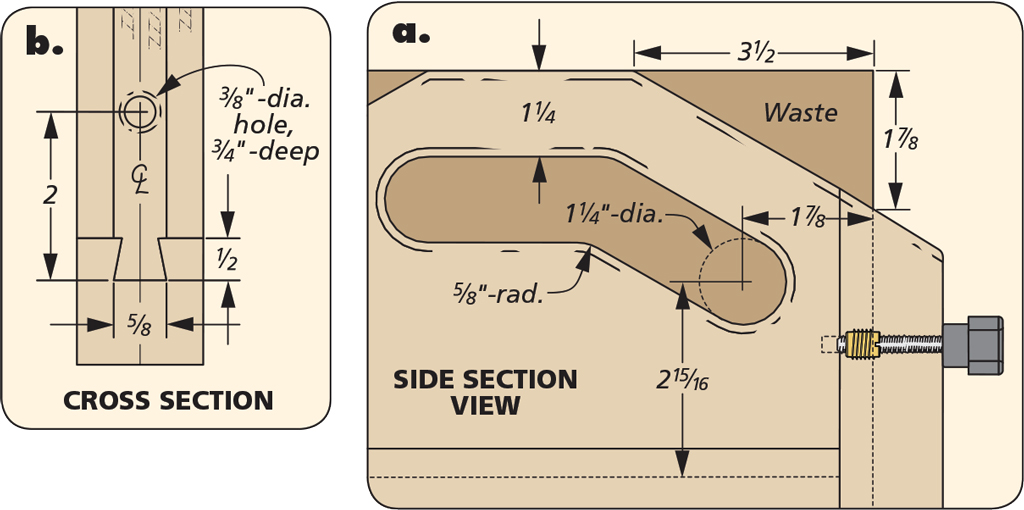

Dovetailed Inserts. The push block has two sacrificial parts, one on the bottom and one on the back. The heel pushes the stock and has a slot cut in it for a studded knob. The knob can be used to adjust the heel for different thicknesses of stock.

Dovetailed Inserts. The push block has two sacrificial parts, one on the bottom and one on the back. The heel pushes the stock and has a slot cut in it for a studded knob. The knob can be used to adjust the heel for different thicknesses of stock.

The base and heel are dovetailed onto the handle and slide off for easy replacement. When I make these parts, I always make a couple of feet worth so I can quickly replace them when they get chewed up.

The base and heel are dovetailed onto the handle and slide off for easy replacement. When I make these parts, I always make a couple of feet worth so I can quickly replace them when they get chewed up.

Special Offer