Best Bar Clamps Will Increase Precision & Accuracy

Woodworking clamps assure your projects' precision, efficiency, and accuracy. So, choosing the right one for your needs and preferences is critical. Unfortunately, there are a lot of woodworking clamps in the market, which may make finding a suitable model for you quite tricky. One of the widely used woodworking clamps suitable for multipurpose gigs is the bar clamp. These tools are also known as F-clamps and speed clamps. Investing in the top bar clamps in 2024 will allow you to employ uniform pressure on your woodworking and metal projects.

Plus, bar clamps add stability and firmness to your projects when you are gluing, cutting, drilling, or filing away at the wood or any other material. Hence, we have handpicked the top 5 bar clamps for your ease, along with a comprehensive guide.

Our Top Picks

- Best Overall: KOTTO Bar Clamp Shop Now ➔

- Runner Up: Bessey Economy Clutch Style Bar Clamp Shop Now ➔

- Honorable Mention: Jorgensen One Hand Bar Clamp Shop Now ➔

- Contender: WEN Steel Bar Clamp Shop Now ➔

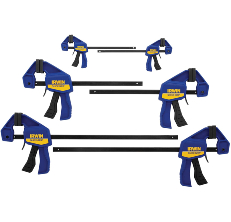

- Also Consider: IRWIN QUICK-GRIP Bar Clamp Shop Now ➔

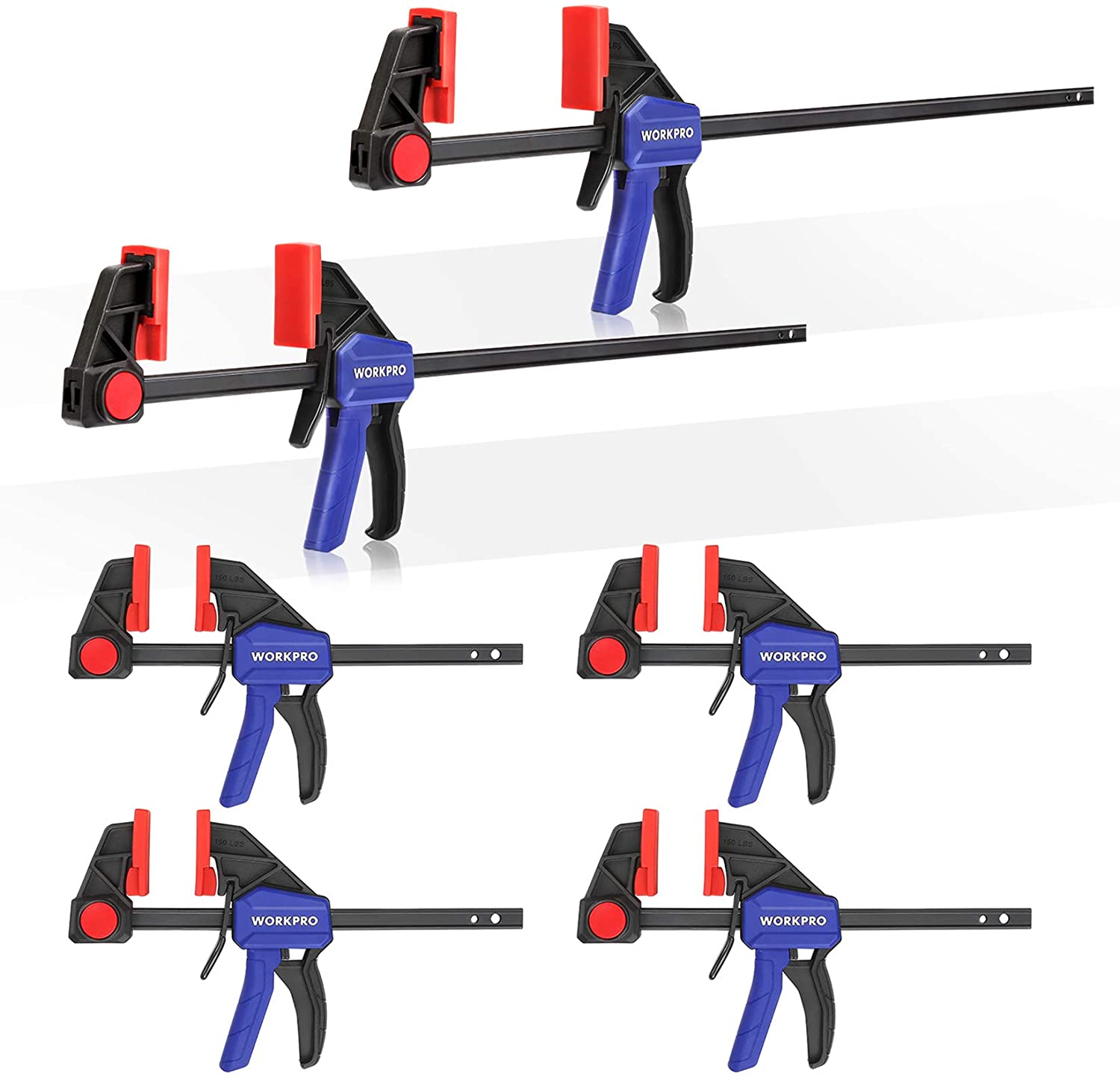

- WORKPRO Bar Clamp for Woodworking Shop Now ➔

What is the Best Bar Clamp in 2024?

Best Overall

The KOTTO Bar Clamp is an ideal solution for a wide range of light-duty woodworking, cabinetry, metalworking, and other DIY needs. This heavy duty clamps set includes two pieces of 6-inch bar clamps and two-pieces of 8-inch bar clamps, as well as a handy carrying case for convenient storage. The 6-inch clamps can be set to spreaders up to 13 inches while the 8-inch clamp is capable of being used as a spreader for sizes up to 20 inches. High-quality aluminum construction along with a durable plastic handle make this tool set incredibly sturdy and reliable.

Pros

- Incredibly sturdy and reliable

- Versatile sizing

- Great for woodworkers

Cons

- Release button can be difficult

Key Features

This bar clamp features a pistol grip with squeeze trigger, which allows for fast and accurate holds on your workpiece. There is also a quick-release button, which makes adjustment of the jaw simple and easy. Removable soft PVC pads provide superior grip while also protecting surfaces from any potential damage that may be caused by the clamping tool. Overall, this is an excellent choice for hobbyists, carpenters, cabinet makers, woodworkers, metalworkers and professional tradespeople of all types who are looking for reliable and efficient tool kit that will last them for many years to come.

Runner Up

The Bessey GSCC2.524 is the best woodworking bar clamp given its clutch-style holding mechanism. This clamp is robust, agile, and adaptable, making it ideal for a wide range of tasks and applications. The model, in particular, is constructed of highly durable materials. The metal has a protective finish and a zinc finish rail, which can bear great force. Protective cushions are also included on both the top and bottom jaws, which will ensure minimal to no indentations.

Pros

- Manufactured with solid and long-lasting material

- Contains protective coating for maximized safety

- Lightweight

Cons

- Not suitable for industrial application

Key Features

This Bessey bar clamp is considered one of the best for its lightweight and protective coatings. Another noteworthy aspect of the CC2.524 is its maneuverability. Weighing only 2.1 pounds, this device is effortless to travel, clamp, and store,

Honorable Mention

The Jorgensen 24′′ one-hand bar clamp is a more heavy-duty and premium alternative if you’re seeking something a little more special. We have dubbed this device our premium choice because it is effortless to use, extra-long, and produces a lot of force. However, it also comes with a hefty price to match these premium features. The Jorgensen 24′′ bar clamp is a one-handed clamp with a load limit of 300 pounds that can open up to 2-feet long. Plus, it’s composed of high-carbon steel, assuring that it will last a long time.

Pros

- MMade up of durable and sturdy material

- Easy to use

Cons

- It is a bit costly compared to other options

Key Features

The Jorgensen clamp is also quite pleasant to use. The quick-release lever and contoured grip add to the product’s reliability. This makes it more comfortable to use and allows you to swiftly and efficiently relieve the pressure.

Contender

The WEN 10236F2 quick-adjust steel bar clamps are well-known clamps that offer micro-precision and comfort. A 36-inch rail and a 2-inch throat are included. Additionally, the device has a micro-adjustment knob for added grip.

Pros

- Micro-adjustment knob is included

- Non-scratching pads are included

Cons

- Rubber is prone to loosening

- Not built with long-lasting materials

Key Features

At the same time, these steel bar clamps have their own set of characteristics as they include a quick-adjust function that allows you to close the clamp without pushing any buttons. Furthermore, the jaws include non-marring pads, so you can work without worrying about scratching your products.

Also Consider

The pack bar clamps of the Irwin quick-grip provide an excellent grip and non-marring pads to protect your project from abrasions and scrapes. The quick-release trigger in this one-hand operation may release the clamps immediately. It uses 140 pounds of clamping force to keep the workpiece together. The clamps are constructed of resin and have hardened steel bars providing maximized durability.

Pros

- One-hand triggers for user’s ease

- Sturdy, robust, and long-lasting

- Guaranteed for a lifetime

Cons

- This clamp is not ideal for large projects

Key Features

These clamps are simple to use and are perfect for little jobs or working in tight areas. The system of measuring is in inches. A lifetime warranty backs it. These bar clamps have good ratings and are solid and durable, ideal for small jobs and limited areas.

The clamping force of the Workpro bar clamps can provide 150 pounds of load. The hardened steel rods and nylon reinforced body provides excellent resistance and endures extensive force. These bar clamps function as spreaders with a unique quick-change button design. The non-marring, interchangeable pads are constructed of a flexible substance with a non-slip texture, which improves the total gripping force.

Pros

- Unique quick-change button design

- Fast-release latch

- Removable, non-scratching pads

- Ergonomic grip for comfort

Cons

- Only suitable for small workpieces

Key Features

The fast-release latch enables quick and easy adjustment and locking of the wood clamps. When used, the ergonomic grip and dipping plastic on the fast-release latch provide comfort. In addition, this particular bar clamp offers a robust, durable, and flexible performance.

Best Bar Clamps Buying Guide

When choosing the top bar clamps for your DIY and construction projects, the expanse of available choice, features, and technical specifications can make or break your decision. This buying guide will demystify the whole process for you because a bar clamp is one handy and efficient tool that will make the wood and metalworking projects insanely easier.

What Is a Bar Clamp?

The bar clamp is a wooden clamp used in different woodwork. Supported via a metal tube, the bar clamp provides a sturdy hold due to its parallel jaws situated on either side. Suitable for versatile uses, the bar clamps can secure heavy-duty projects from tightening to spreading purposes with an easy button switch or quick-release lever mechanism.

Essential Considerations To Look For in a Bar Clamp

Size

When purchasing bar clamps, get one or two sizes larger than you will require since smaller projects may be held in large clamps but not vice versa. However, excessively hefty clamps might be harmful to the work on a small job, causing distortion and even fracture. The neck depth must also be sufficient to cover the work. This is typically not an issue for little work, but larger pieces need the clamp to acquire a fair distance across the work for uniform pressure distribution.

Material

Bar clamps are often constructed of steel or metal with a powder coating for strength and durability; however, others are plastic. The hard plastic is preferable to soft plastic since it cracks more easily. The most excellent handles are made of hardwood. They’re delicate, won’t scrape your skin, and will last a year. Similarly, compared to lightweight aluminum material, carbon steel and cast iron clamps provide more strength and durability.

Durability

Bar clamps must be solid and durable. Because most clamps are purchased for heavy-duty clamping, the steel bar must be strong enough to support the weight of the project. Another factor to consider is the jaws. The jaws of a clamp make contact with the wood’s surface. As a result, all of the pressure applied to the jaws is transmitted to the clamping faces.

If the work is clamped directly, the pressure is confined to a small region, causing the work to be destroyed. On the other hand, more prominent faces will not leave indentations since the pressure is distributed across a larger area.

Pricing

Last but again not least, for some of you, the price may be an essential consideration. Any clamp’s price is determined by its quality, adaptability, material, durability, and various other factors. However, contrary to popular belief, clamps are quite cost-effective and economical to invest in. You can pick bar clamps for as low as $30.

However, depending on your needs, clamp variants are as expensive as $100 for more sophisticated features and exceptional performance.

However, a bit of friendly advice is not to shell out extra dollars for excessively premium features if you aren’t a professional woodworker. So, think about your project’s requirements first and then set your budget accordingly.

Technical Factors You Should Consider When Choosing the Right Bar Clamps

Consider the manoeuvrability of clamp

One of the most essential components when selecting a bar clamp is its ability to maneuver at different angles. Not all clamps will offer that kind of freedom of movement, especially the ones that are too heavy or difficult to hold. However, extreme maneuverability can negatively impact the clamp’s holding power; therefore, try to strike a balance between two factors to fulfill your requirements.

Consider the clamping power

The primary function of a clamp is to apply steady pressure on the objects. Similarly, under clamping and overt clamping force can mess up your projects resulting in uneven pressure or imprints. Therefore, look for a clamp that has enough holding strength or power with adequate clamping power. However, the most crucial aspect of determining the clamping power of your tool, you must also consider the material and its force threshold. For instance, loose-grained wood may require less clamping force than dense wood.

Consider the handle that feels right

The clamps basically act as your third hand, allowing you precision and efficiency when you are working with tough materials such as wood or metal. If you are a passionate woodworker with constant use of clamps, then you should definitely think about getting a handle that feels comfortable in your hands. The material of a handle is secondary for comfort; however, it can impact the durability of the clamp. Therefore, bar clamps that essentially have a contoured handle with ergonomic designs should definitely be your first choice.

Types of Clamps To Choose From

One hand clamp

One-handed clamps may be fitted using just one hand, as the name implies. Then, to tighten the clamp, you just simply have to squeeze the handles. They do, however, have a limited clamping force (about 100 kg).

Spring clamp

Spring clamps resemble pliers more than anything! The jaws employ a spring to create force, which, although convenient, limits the clamp’s ability to exert a lot of force.

Pipe bar clamps

When you are on the hunt for heavy-duty clamps that provide high-strength sturdiness, pipe bar clamps are your best bet. Whether you are cutting up planks or gluing the boards, pipe bar clamps maintain the required pressure.

F-clamp

This particular bar clamp is a lightweight option with a smaller scale resembling the alphabet ‘F’ when seen from the sides. F-clamps are available in diverse width sizes, from 6-inches to as long as 48-inches. The knob mechanism of these bar clamps allows jaw movement for pressure initiation.

To understand more about clamps and the utility of bar clamps, check the useful video from ‘Stumpy Nubs’.

PEOPLE ALSO ASKED

What is the purpose of a bar clamp?

The bar clamps feature adjustable arms that may be readily expanded or narrowed to fit the requirements of the workpiece. This clamp is particularly useful since it requires fewer screw turns to hold the item firmly. The proper usage of a bar clamp is essential for woodworking, especially when gluing edges.

Why should you buy a clamp which doesn't flex?

A key component is strength. Of course, it’s vital to have enough clamping force, but it's also critical to have bar clamps that do not bend when loaded. Flexing decreases the amount of stress applied to your project item while also shortening the life of the clamp.

What is the appropriate force to operate the clamp?

You don't want to use too much power to avoid damaging the workpiece. It's possible to leave scars if you tighten it too tightly, which is why doctors recommend wearing protecting pads. On the other hand, you want enough pressure to prevent the material from moving throughout the operation without overtightening it.

Which type of clamp is used for general purposes?

When it comes to fundamental duties, C or G-clamps are the most frequent choice. This is because they are inexpensive and ideal for a broad range of activities, particularly those involving DIY chores in your garage. As a result, they are the most commonly purchased by consumers.

Article Contributors

The Woodsmith Review Team’s product reviews and in-depth guides are here to help you choose the best tools and gear to build great-looking projects confidently. Woodsmith is reader-supported: When you buy through links on our site, we may earn an affiliate commission. Large language models (like Artificial Intelligence) may have been used in the research and creation of the content.

Inquiries regarding specific articles or product testing should be sent to aimperiapt@gmail.com