The Best Scroll Saw Blades

Our Top Picks

- Best Overall: FOXBC Scroll Saw Blade Shop Now ➔

- Most Durable: OLSON Scroll Saw Blade Shop Now ➔

- Best Precision: Flying Dutchman Scroll Saw Blade Shop Now ➔

- Best Small Projects: Skil Scroll Saw Blade Shop Now ➔

- Easiest Installation: BOSCH Scroll Saw Blade Shop Now ➔

- Buying Guide: Scroll Saw Blades

- People Also Asked

- What type of scroll saw blades should I use for woodworking projects?

- How can I tell which size scroll saw blades will work best for my project?

- What material should I usually use for blades?

- How can I ensure that my scroll saw blades are properly sharpened?

- Are there any special considerations I should keep in mind when choosing the right scroll saw blades?

- How often should I replace scroll saw blades?

- Does the type of scroll saw determine the type of blade to use?

- Should the speed of the scroll saw affect my blade choice?

- What features should I look for when purchasing blade sets or individual blades?

- Are special accessories like tensioning systems necessary for safe and effective use of scroll saw blades?

- Related Reviews

Comparing the Top Scroll Saw Blades of 2024

Best Overall

Ideal for precisely sawing hardwood, soft wood, plastic, copper, and other soft metals, this scroll saw blade is made from corrosion-resistant SK5 Japanese carbon steel, yielding better strength and increased longevity. With a simple installation process and ease of handling, this blade is sure to provide efficient and smooth performance.

The blades in this set are designed to fit 15-inch and 16-inch machines that require five-inch pin end blades. The package contains 48 individual packets of blades in a variety of TPI levels. There are 12 sets of 10-teeth-per-inch blades, 15 teeth-per-inch blades, 18 teeth-per-inch blades, and 24-teeth-per-inch blades. This range guarantees that no matter what kind of materials you’re working with, there’s a perfect blade for the job. Due to its versatility and a wide array of features, the FOXBC Scroll Saw Blade wins the top choice on our list.

Pros

- High-quality, durable product

- Easy to cut and shape

- Wide range of sizes available

- Affordable price for the quantity of material

Cons

- May not be suitable for large projects

Most Durable

Manufactured in the USA, the OLSON SAW FR49501 Scroll Saw Blade is made out of highly durable stainless steel. These blades are designed to work well with hard and soft wood as well as other materials like plastic. The set includes 18 five-inch pinned blades and six blades each of FR42401, SC41101, and SC41201 blades. All of these scroll saw blades are easy to install and handle.

More specifically, the FR42401 blade is especially helpful for intricate designs and small pieces. The SC41101 blade offers a smooth cut while the SC41201 blade can be used for fast cuts. All of the blades provide amazing cutting performances due to their precision-focused teeth. These blades can be used on almost any machine that requires five-inch pinned blades, offering optimal performance on all types of materials.

Pros

- Highly durable blades

- Great value for your money

- Easy to install

- Wide selection of tooth count

- Excellent cutting performance

Cons

- Not suitable for cutting very thick materials

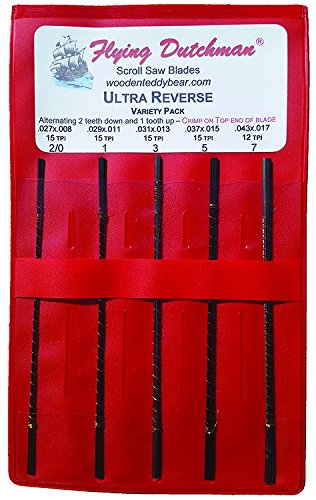

Best Precision

The Flying Dutchman Ultra Reverse Scroll Saw Blade pack brings an all-in-one solution for the woodworking enthusiast. Top-grade German manufacturing paired with precision engineering ensures that these high-quality, hardened-steel blades are strong and durable.

Each blade is five inches long while also being pinless, which allows for a sharper cutting edge with minimal splintering on the underside of the project. Their ultra reverse design means every third tooth is reversed, which ensures a clean cut and smooth surfaces. This scroll blade pack includes a dozen blades of multiple sizes for versatile uses.

Pros

- Allows for precision work

- Blade fits in much smaller pilot holes

- Conveniently packaged together

- Increased cutting ability for various projects

Cons

- Can be difficult to change blades

Best Small Projects

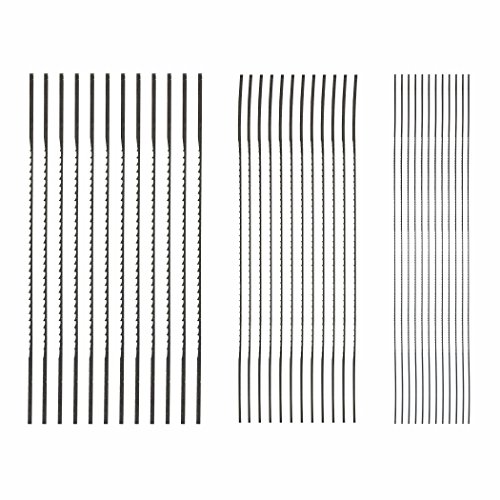

The SKIL 80182 Plain End Scroll Saw Blade is an essential tool for anyone looking to make intricate cuts. The set includes 36 blades: 12 with 28 teeth per inch, 12 with 11.5 teeth per inch, and 12 with 9.5 teeth per inch. The variety of these blades allows you to choose the right blade for the material you are working with. Plus, the blades are crafted from premium-grade steel.

These blades are also sharpened for precision to create cleaner cuts with even the most delicate shapes. The set is great for sawing all kinds of wood, plastics, and non-ferrous metals. Whether you’re a professional contractor or you just need to do some work around the house, this set has you covered. These blades fit most scroll saws, so it can be very easy to get started with these scroll saw blades.

Pros

- Excellent value for the price

- Suitable for a few pieces of cutting

- Prompt refund when returned

- Sharp and durable blades

Cons

- May not be compatible with all saws

Easiest Installation

The Bosch Pin End Scroll Saw Blade is an excellent choice for a variety of cutting needs. Its premium-grade steel construction ensures long-lasting and reliable performance. The blades have been precision-sharpened to make cutting intricate shapes easier, making them great for all types of wood, plastics, and non-ferrous metals.

They have a pin-end design to help with faster installation when paired with a scroll saw while also making them suitable for a wide range of saw models. These blades come in two styles, including pinned and plain, so you can choose the one that best meets your project needs.

Pros

- Good value for your money

- Cuts thin wood and soft metal easily

- Fits well into existing spaces

- Easy to install

Cons

- May not work well with all saws

Buying Guide: Scroll Saw Blades

If you are looking to take your woodworking to the next level with intricate detailing, a scroll saw is a woodshop staple. To ensure your cuts are up to snuff, investing in the right scroll saw blades is a must. We’ve compiled the key features to consider when selecting scroll saw blades for your next project. Let’s dive in!

Material of Blade

The material of the scroll saw blade should be the first thing you consider when choosing the right blade for your needs. Most blades are made from high-speed steel (HSS), so it is best to stick with this material.

There are some blades made from carbide, which are specially designed for very thick materials. While they can last longer than HSS blades, carbide blades are often more expensive and harder to find.

Teeth per Inch (TPI)

The number of teeth per inch (TPI) is important because it determines how fine or coarse the cut will be. Generally speaking, the higher the TPI count, the finer the cutting action will be. A rule of thumb is that small blades usually have a higher TPI than large blades, so if you need to make tiny intricate cuts, then a higher TPI may be more suitable.

Skip Tooth

Depending on the kind of application you are going to use the scroll saw for, you may want to consider whether or not it has a skip tooth pattern or design. Skip tooth blades tend to cut faster and require less pressure when making cuts, but they can also cause more vibration in the saw arm, which can lead to additional wear and tear over time.

Type of Teeth

You will want to consider the type of teeth on the blade that you are thinking about buying. There are several types of teeth, including plain, spiral, regular skip, or double skip. Plain blades are the most common, and they work best on thinner materials or curves that have fewer depth variations. Alternatively, spiral teeth provide an even cut across thicker materials. Regular skip and double skip blades are best used for hardwoods since they help reduce clogging with more dense materials.

Length of Blade

The length of the blade is also important, as this will determine how deep you can cut into a material as well as how much area you can cover with each stroke you make with your saw. Generally speaking, longer blades can be used for deeper cuts while shorter blades are better equipped to handle more shallow cuts on smaller projects.

Thickness of Blade

The thickness of the blade is measured in fractions of an inch. Thicker blades tend to cut more smoothly and much faster than thinner blades, but they can also cause greater stress on your scroll saw motor, which can lead to damage if used too often or aggressively.

Kerf Width

The kerf width is the width of the cut that the blade makes when in use. The smaller the kerf width, the finer the details on the project will be once complete. This measurement is usually given in fractions of an inch, like 0.025 inches or 0.045 inches, so it’s important to pay attention to this when selecting a blade for your project needs.

Shank Size

The shank size refers to the diameter of the shank where it attaches to the scroll saw itself. This should match up with the model scroll saw you’re using for your new blade to fit correctly and remain secure while in operation.

Price

It should come as no surprise that different brands and sizes of scroll saw blades come with different price points attached to them. Some manufacturers offer discounted packages when buying in bulk, and this is good news if you’re looking for long-term savings. Similarly, most retail stores carry individual blades that can accommodate just about any budget.

Quality of Construction

When buying any product or tool, it’s always important to consider the quality of the tool’s construction. Look for high-grade steel, like stainless steel, chromium-vanadium alloy steel, or molybdenum-vanadium alloy steel. These types of steel are rust-resistant, and they can provide superior durability.

Manufacturer’s Reputation

Last but not least, check for feedback from other customers about certain brands and models before investing in a product. It’s important to look at online customer reviews about particular brands and models when searching for the right kind of blade. This way, you can get an idea ahead of time about how well-made they are as well as how trustworthy each manufacturer is concerning the products’ performance and customer service.

People Also Asked

What type of scroll saw blades should I use for woodworking projects?

For most types of woodworking projects, fine-toothed, skip-toothed, or hook-tooth scroll saw blades are recommended. These blades have small teeth that cut slowly. They reduce the risk of tear outs and provide a neat, polished finish to your projects as well.

How can I tell which size scroll saw blades will work best for my project?

The size of the blade you’ll need will depend on the type and thickness of the material being cut. The thinner materials will require a finer blade, while thicker materials will require a coarser blade. In addition to the type and thickness of the material, you should also consider the complexity of the project as larger blades may struggle to make more intricate cuts.

What material should I usually use for blades?

Generally, stainless steel scroll saw blades are preferred as they are strong and durable. They can be sharpened easily, resulting in precise cuts across a variety of materials.

How can I ensure that my scroll saw blades are properly sharpened?

Scroll saw blades can be sharpened with a file or grinding wheel if done correctly. It is important to use caution when working with these tools as over-sharpening may cause damage to the blade or decrease its lifespan. A reputable blade sharpening service may also be used to ensure a high-quality outcome.

Are there any special considerations I should keep in mind when choosing the right scroll saw blades?

When selecting a blade, there are several factors to consider, such as the material type, thickness, cutting speed, and desired finish. You should also take into account whether the blade needs to be able to handle curves or intricate details in your project design. For best results, it is important to select a blade that is well-suited to your project's requirements.

How often should I replace scroll saw blades?

It depends on how often you use your scroll saw and how hard you push when using it. Generally, blades will last anywhere from 15 hours to 20 hours of cutting time before needing to be replaced as a result of dullness. Ultimately, keeping your blade sharpened regularly will help you prolong your tool’s lifespan.

Does the type of scroll saw determine the type of blade to use?

Yes, different types of scroll saws require different types of blades depending on their size and power requirements. It is important to check your user manual or contact the manufacturer if you are unsure which type of blade is most suitable for your device.

Should the speed of the scroll saw affect my blade choice?

Yes, because higher speeds generate more heat, which can cause wear on scroll saw blades more quickly than with lower speeds. So, choosing a higher tooth count or finer tooth count blade may be necessary depending on the speed at which you are running your saw’s motor or flywheel belt system.

What features should I look for when purchasing blade sets or individual blades?

When choosing individual blades or sets, look for features such as tension adjustment capabilities and heat treatment for improved durability as well as compatibility with your particular model of scroll saw. That way, you’ll get maximum performance from your blade set or individual blade purchase.

Are special accessories like tensioning systems necessary for safe and effective use of scroll saw blades?

Yes, because using accessories such as tensioning systems helps reduce vibrations during operation and increases accuracy when making intricate cuts. This will give you better control over your cuts while reducing the risk of accidents.

Article Contributors

The Woodsmith Review Team’s product reviews and in-depth guides are here to help you choose the best tools and gear to build great-looking projects confidently. Woodsmith is reader-supported: When you buy through links on our site, we may earn an affiliate commission. Large language models (like Artificial Intelligence) may have been used in the research and creation of the content.

Inquiries regarding specific articles or product testing should be sent to aimperiapt@gmail.com