The Best Table Saw Blades for Precise Cuts

xr:d:DAFisPmaWTo:3,j:4537764299,t:23051209

If you’re a DIY enthusiast, you understand the importance of having a reliable table saw. You need a saw to make precise cuts to accomplish the task. But when it comes to table saws, the saw itself isn’t the only important element. The saw blade is equally important.

A table saw blade can make a huge difference in the quality of your cuts, and it’s essential to find the right blade for the job. In this guide, we’ll explore features and reviews of the leading blades of 2023. With our help, you can find the perfect saw blade to suit your specific needs.

Our Top Picks

- Best Overall: Overpeak Table Saw Blade Shop Now ➔

- Best for Resharpening: Luckyway Table Saw Blade Shop Now ➔

- Easy Installation: WEN Table Saw Blade Shop Now ➔

- Best for Carpenters: DEWALT Table Saw Blade Shop Now ➔

- Best Tear-Out Reduction: Freud Table Saw Blade Shop Now ➔

- Buying Guide: Table Saw Blades

- People Also Asked

- What is the best table saw blade for my project?

- What is the difference between a combination blade and a rip blade?

- How do I change the blade on my table saw?

- How tight should a table saw blade be?

- How do I clean and maintain my table saw blade?

- Should I use a thin or thick kerf blade?

- What are the types of blades available for table saws?

- How do I select the right number of teeth for my blade?

- Can I make my own table saw blade?

- Are there any safety tips I should follow when using a table saw blade?

Comparing the Top Table Saw Blades of 2023

Best Overall

The Overpeak Table Saw Blade is constructed from tougher tungsten carbide for up to five times longer cutting life than other blades on the market, which makes it ideal for extended use in any project. It features six laser-cut expansion slots and four laser-cut stabilizer vents that trap noise and vibration, keep it cool, and reduce blade warping. The alternate-top bevel (ATB) teeth on this saw blade also provide an extremely smooth cut and perfect finish every time.

In addition to its impressive cutting capabilities, this saw blade can be used in many machines, such as a circular saw, table saw, and miter saw. It has no trouble handling high-speed rotations up to 6000 RPM with ease. Moreover, this saw blade has multiple uses across various materials, including wood, plywood, and laminate. This saw blade wins the top spot for its cost-effective durability.

Pros

- Good price for great quality

- Cuts smoothly and accurately

- No burn marks, no chipping/tear out

- Maintains sharpness over time

- Excellent for hardwood cutting

Cons

- Blades may be too thick

Best for Resharpening

The Luckyway Table Saw Blade Set contains one 32T blade and one 60T blade, both of which have a five-eighths-inch arbor, making them suitable for use with most standard saws. The blades are made from fully hardened steel bodies that ensure precision cutting and resist bending and deflection for truer cuts. The blades are designed with an ATB (alternating top bevel) offset tooth design, which scores the surface of the wood before the cut, ensuring clean, smooth, and splinter-free cutting. The tungsten carbide teeth provide excellent wear and heat resistance, allowing for faster cutting speed and an improved finish. These blades can handle a variety of materials such as softwood, hardwood, plywood, chipboard, multi-board, panels, MDF, plated and counter-plated panels, laminated and bi-laminate plastic, as well as FRP. This makes them ideal for a range of different applications such as cross-cutting, rip-cutting along the grain, or even precision-cutting jobs.

Pros

- Cutting results are crisp and smooth

- Long-lasting and reliable results

- Great value for the price

- Durable teeth

Cons

- May not work for all heavy-duty projects

Easy Installation

The WEN Table Saw Blade has a 10-inch diameter and a 5/8-inch arbor (15.88 mm). It has a maximum rated speed of up to 6000 RPM and is perfect for cutting through both hardwoods and softwood varieties.

This saw blade is designed with 40 carbide-tipped teeth, providing the ideal amount of power for general-purpose wood-cutting needs. The ultra-thin one-tenth-inch kerf of this saw blade allows it to provide clean, precise cuts every time. As an added benefit, the WEN BL1040 is compatible with most 10-inch miter saws, job site saws, and table saws, making it a great choice for professional and DIY woodworkers alike.

Pros

- Clean and smooth cuts

- Great value for money

- Highly durable and sturdy

- Easy to install

Cons

- Could have pitch build-up over time

Best for Carpenters

The DEWALT Table Saw Blades feature tough tungsten carbide material that stays sharper for longer, providing a reliable and consistent cut every time.

The blades are designed with a thin kerf, enabling them to make smooth and fast cutting actions. These blades can handle both miter saw and slide miter saw jobs, making them a versatile tool to have in your arsenal. Thanks to the computer-balanced plate, you can expect improved accuracy and a better finish on all cuts. Its arbor size will fit into most common table saws.

Pros

- High-quality blades

- Able to cut through tough materials

- Great value for the price

- Compatible with many saws

Cons

- Can be too thin for certain projects

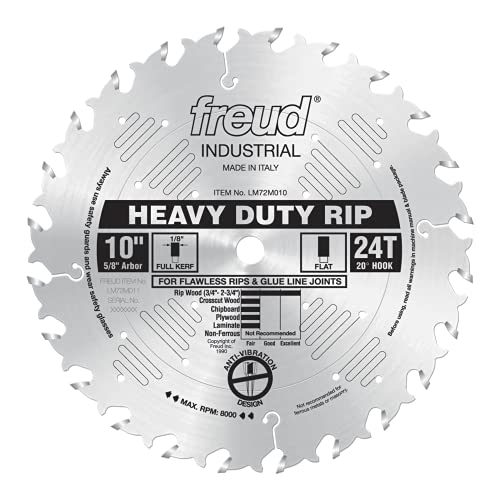

Best Tear-Out Reduction

The Freud Table Saw Blade is crafted with premium TiCo Hi-Density Carbide; the blade offers maximum performance with minimal effort. Its extra-large, flat tooth design leaves a smooth finish without requiring sanding or jointing, making it a great time-saver for those working long hours.

The blade also features laser-cut anti-vibration slots designed to drastically reduce vibration and sideways movement in the cut. And with its silver ice coating protecting against corrosion and pitch build-up, this saw blade is sure to last for years of use.

Pros

- Economical and dependable

- Makes smooth cuts

- Solid weight with a mirror finish

- Teeth provide nice square, sharp corners

Cons

- May not be suitable for cross-cutting

Buying Guide: Table Saw Blades

Whether a DIY enthusiast or a professional, one thing remains true: a table saw is an essential piece of equipment, but a table is nothing without an exemplary blade. With so many table saw blades on the market, it can be hard to choose the right one for your needs. We’ve outlined the features to look for when shopping for a table saw blade below, so you can purchase confidently.

Number of Teeth

The number of teeth on the blade determines the quality of the cut. Blades with a higher number of teeth are designed for finer cuts, while blades with fewer teeth are used for fast and aggressive cuts. You will need to determine whether you need an alternate top bevel or a flat top grind.

Kerf Width

As the blade cuts, it removes a certain amount of material. This is referred to as “kerf width.” A thicker kerf removes more material, which affects capacity and power consumption. Most tables saw blades range in thickness. For fine, clean cuts using thin materials, you may want to select a thinner kerf width, while thicker materials will require a wider kerf width to reduce power consumption and stress on the saw motor.

Tooth Profile

Tooth profile refers to the shape of the blade’s teeth. This is where most of the cutting takes place and can affect chip-load capacity, smoothness of the cut, and deflection resistance. There are several tooth profiles available, including flat top grind (FTG), triple chip grind (TCG), and high alternate top bevel (ATB). Flat top grind (FTG) has flat teeth angled in a “V” pattern, which is best for ripping applications as it produces a smooth surface finish with minimal denting or chipping. Triple chip grind (TCG) has three angles in each tooth design, which is better for laminates and plastics due to its chip control. High alternate top bevel (ATB) has alternating teeth beveled on both sides, which results in smoother cuts and less deflection on hardwoods.

Hook Angle

Hook angle is how much the blade’s teeth lean forward or backward. This affects aggression and how easily the material can be pushed through or pulled away from the blade without binding or kickback. Large hook angles will cause less binding on thicker materials, while small hook angles are ideal for ripping thin materials or narrow grooves.

Plate Thickness

Plate thickness refers to how thick the body of the blade is. This affects blade rigidity, which helps reduce deflection when cutting heavier materials as well as reduces stress on the saw motor during long cuts. The thinner plates are perfect for thin materials, while the thicker plates are better suited for thick materials.

Material

Different materials result in different performance characteristics. Blades made from carbon steel are durable and strong, but they will lose their edge more quickly than blades made from tungsten carbide-tipped steel or stellite-tipped steel. Additionally, premium-grade materials will increase the cost, so it is important to consider your budget when selecting blade material.

Diameter

The diameter of your saw blade will affect cutting depth and stability when making certain applications, such as dados and rabbets. Choosing a large-diameter saw blade gives you more stability and deeper cuts than smaller-diameter saw blades. For dado sets, larger arbor-size woods require larger saw blade diameters in order to fit properly.

Arbor Size

Arbor size must match up with your saw’s arbor size in order to avoid wobbling or incorrect assembly resulting in unsafe conditions. Always measure your saw’s arbor size before purchasing a new saw blade in order to make sure it fits correctly.

Quality

Investing in a quality table saw blade ensures you get an efficient cut without sacrificing longevity. Look for trusted brands such as Freud, Forrest Saw Blades, Oshlun Saw Blades, CMT Industrial Solutions, and Diablos Saw Blades, whose products are made with higher quality materials and construction methods that are designed to last longer than other inferior brands on the market today.

People Also Asked

What is the best table saw blade for my project?

The best table saw blade for your project depends on the type of material you are cutting and the finish you require. You can use a combination blade to cut both softwood and hardwood or a ripping blade for faster cuts in softwood. A crosscut blade will provide a cleaner cut in hardwoods, while an angle-ground or alternate-top bevel blade will give you excellent performance when jointing or planing.

What is the difference between a combination blade and a rip blade?

A combination blade is designed for both ripping and crosscutting wood, while a rip blade is specifically designed for fast, efficient cuts in softwood. The teeth of a rip blade are angled so that they pull the wood fibers apart as it cuts, while the combination blades have teeth that are alternately angled, which gives them the ability to do both ripping and crosscutting.

How do I change the blade on my table saw?

The process of changing the blade on your table saw depends on the make and model of your saw. You should unplug your saw from the power source, remove any guards or dust collection systems, and loosen the arbor nut with a wrench. You can then remove the old blade and slide in your new one before tightening the arbor nut again.

How tight should a table saw blade be?

When replacing or tightening a table saw blade, you should only tighten it enough to keep it from moving since overtightening can cause damage to both the blade and saw components as well as reduce its cutting performance. Tighten the arbor nut just until it's snug. No additional force is necessary.

How do I clean and maintain my table saw blade?

Before using your table saw, you should always inspect it for any signs of wear or damage on both the teeth and body of the blade. Keep dull blades sharpened or replaced regularly and store them in a cool, dry place away from moisture and extreme temperatures to ensure optimal cutting performance. Wiping down your blades after each use with an oil-based lubricant can also help keep them from rusting.

Should I use a thin or thick kerf blade?

The materials being cut and the thickness of each piece will determine the thickness of the kerf (the amount of material removed by each pass of the saw). Thin kerf blades are better suited for cutting thinner materials such as plywood or laminates, while thicker kerf blades are better suited for thicker materials such as hardwoods or plastics.

What are the types of blades available for table saws?

There are several types of blades available for table saws, including ripping blades, crosscut blades, combination blades, dado blades, slot cutters, circular saw blades, and more. Each type of blade is designed for specific tasks such as making straight cuts (rip blades), miter/angle cuts (crosscut blades), plunge cuts (dado blades), etc., so choosing the right one for your particular application is essential in order to achieve optimal results from your table saw projects.

How do I select the right number of teeth for my blade?

The number of teeth on your table saw blade will determine how smooth or rough your finished cut will look depending on the material being cut and what type of finish you would like to achieve from your project. Blades with fewer teeth tend to leave rougher edges, while those with more teeth tend to leave smoother edges with less tear-out. The blades with more teeth may take longer when making cuts through harder materials, such as hardwoods or plastics, due to their size and the amount of material removed per pass over them.

Can I make my own table saw blade?

Yes, it is possible to make your own table saw blade, but it requires precision welding skills and knowledge along with access to welding supplies such as steel bars, heating rods, angle grinders, etc., so it's best left to those who are experienced. All safety protocols should be followed when using welding equipment to avoid creating hazardous conditions.

Are there any safety tips I should follow when using a table saw blade?

Yes! When using any type of power tool, including a table saw, it is important to always follow basic safety protocols such as wearing protective eyewear and gloves. Ensure that all guards are securely in place. Double-check that both sides of every workpiece are free from debris, and always keep hands away from moving parts.

Article Contributors

The Woodsmith Review Team’s product reviews and in-depth guides are here to help you choose the best tools and gear to build great-looking projects confidently. Woodsmith is reader-supported: When you buy through links on our site, we may earn an affiliate commission. Large language models (like Artificial Intelligence) may have been used in the research and creation of the content.

Inquiries regarding specific articles or product testing should be sent to aimperiapt@gmail.com