The Best Taper Jigs to Make Difficult Cuts With Ease

- Best Overall: Fulton Taper Cutting Jig Shop Now ➔

- Runner Up: Rockler Taper Jig Shop Now ➔

- Honorable Mention: MICROJIG - TJ-5000 for Table Saw Jig Shop Now ➔

- Contender: POWERTEC 71035 Table Saw Angle Cutting Jig Shop Now ➔

- Also Consider: DCT Taper Gauge Jig Shop Now ➔

- Also Consider: Big Horn 19066 Taper Jig Shop Now ➔

The Best Taper Jig Models of 2024 in Detail

Best Overall

Making long rip cuts at various angles can be considerably difficult and tricky but Fulton has made it much easier. Now you can set the desired angle from 1-15 degrees on a table saw by using this taper. It comes with a meter gauge and 24 inches long aluminum rails, having scales and stops.

You can use this taper perfectly for woodworks such as table or chair legs and magazine racks. You can draw markings with the help of scale or mark starting and exit points while doing cuttings. The two bars of the jig are attached with a hinge to make sure that the bars cannot come out while working. You can also use it with a rip fence.

Pros

- Made up of industrial-grade aluminum rails to last long

- Has a backside stop to hold the workpiece in place

- Comes with a built-in adjustable scale for making 3-inch taper per foot

- Can be operated either on the left or right-hand side

Cons

- Sometimes it can create problems holding screws

Runner Up

If you are looking for a taper jig with lengthy cuts then Rockler can be the perfect pick. It comes with extraordinary properties such as heavy-duty hold-down clumps, a simple indexed angle setting system, and a smooth sliding design that make your cutting easy and quick. You can surely set an angle by marking the system and 36 miter bar.

Clamps with non-marring rubber caps avoid any kind of drifting while cutting. Also, the three adhesive strips work as stabilizers for your workpiece.

Pros

- Can cut edges straightly even on rough surfaces

- Large ergonomic push handles for a smooth grip

- Features two hold-down clamps to prevent sliding of the workpiece

- Can fit any standard miter slot measuring 3/8-inch x 3/4-inch

Cons

- You might find it a bit heavier as compared to other taper jigs

Honorable Mention

This is one of the safest and smartest taper jigs in the market. With 26 x 8.75 x 1.75 inches of ideal dimensions and 3.4 pounds in weight, this taper can make precise and accurate cuts 1/8 of a degree.

One of the unique features of Microjig is the GRR-RIPPER 3D push block which allows it to cut 8 sided tapered legs together. You can make taper adjustments vastly between 0-10 degrees angles. Also, memory locks in this taper offer quick repeated cuts of angles.

Pros

- Made of high-quality rust-proof plastic

- You can set the angle with the turn of the dial conveniently

- Allows you to make two-sided tapering cuts at the same time

- Features two separate scales

- Has two micro dials for ensuring precision

Cons

- It needs two additional grippers for safe use

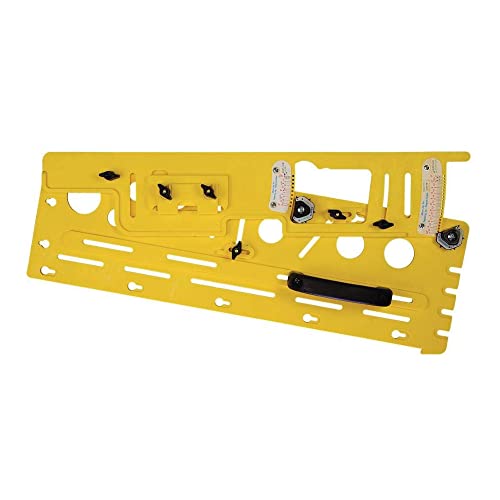

Contender

This lightweight taper jig comes with an ergonomic handle, lock knob, 24 inches long rails with work stops, and laser-etched scale. It helps you in making long cuts ranging from 4.8 degrees to 15 degrees. You can make smooth, accurate, and precise cuts at various angles by using this taper for kitchen tables, chair legs, wooden racks, and more.

This taper has corrosion-resistant technology due to its lightweight aluminum construction. It features a 17 gauge steel laser etched hinge that helps in smooth and sturdy cuttings.

Pros

- Has a high strength to weight ratio for heavy wooden works

- Features graduate scale for getting accurate measurements of inches and degrees

- Aluminum construction has made it durable and reliable

Cons

- The scale is difficult to mount

Also Consider

This table taper is perfect for construction and remodeling your samples. You can make cuts safely and accurately with the help of its removable and adjustable stops. It offers you complete control over your heavy workpieces when making cuts on radial arms or table saw. You can easily set it for both left and right-hand use while cutting table legs, wooden racks, dado cuts, and other wooden structures.

It features an adjustable and readable scale that can mark up to 15 degrees. By using a gauge you can make desired changes. Due to design and effective detailed construction, this taper is easy to use even for beginners.

Pros

- Offers a good cut quality

- Made of sturdy aluminum to last longer

- Feature an easy-to-read graduate scale for accurate measurements

Cons

- As it is lightweight, you can have problems while dealing with heavy workpieces

Also Consider

If you want to make easy cuts on a table saw or radial arms, this taper can serve you better. It comes with a strong metal hinge having outer edges, grooves, and an adjustable stop to improve its sturdiness. The built-in graduated scale is perfect for taking accurate measurements, ranging from 3 inches or 15 degrees.

You can adjust it easily for both right or left-hand use. This taper is made of high-grade aluminum channels that make it sturdy and a great option for long-term usage.

Pros

- Inexpensive, safe, and effective taper

- Easily adjustable for right or left-hand operations

- Comes with T-slotted sides for adjustable stops

Cons

- Use it carefully; otherwise, pins may come out

Best Taper Jigs Buying Guide

Woodworking can be strenuous, and having the wrong tools can make it more tiresome. Getting a taper jig that will be a perfect fit for your needs can take up a lot of your time. We understand the concerns of buyers and have curated a guide to help you make the best decision.

Key Considerations of Choosing the Best Taper Jig

You have to consider some important factors before buying a table saw taper jig.

Material

When you are planning to buy a tool, you should pay special attention to the construction material to be sure that it will last longer. The best table saw tapering jigs are usually made of high-quality aluminum, wood, plastic, or other lightweight but sturdy materials.

Though steel is among the sturdiest elements to make different tools, it is not the top choice by manufacturers due to its weighty composition.

Ease of use

Manufacturers don’t follow the same pattern, and they don’t produce tools that look the same. Tapering jigs come in a variety of shapes and sizes.

In fact, the design differs from one manufacturer to the next. There are, however, several companies that have a similar design, but the features vary greatly. So, choose one that is easy to grab and doesn’t put much strain on your hand.

If you’re new to using taper jigs, consider watching this how-to video from thintz12:

Precision

Many manufacturers are simply offering their tools to make money, but they are elegant in their presentation. Because the main purpose of your taper jig is to make taper cuts, it requires an accurate measurement system. It is possible that your workpiece will be ruined if you do not use an accurate measurement system. So, when you’re looking for a jig, be sure it’s accurate.

Versatility

We are all either right- or left-handed, and complete our tasks using either the right or left hand. Our habit dictates that we use one hand more than the other, whether it be the left or right.

Considering these factors, some companies are now offering taper jigs that can be used with either hand.

Budget

Don’t forget to set a budget before considering the options that are available. All of the other details will fall into place if your budget matches the price.

Assume you’ve completed all of your homework and have decided to purchase one taper jig. It’s possible that you won’t be able to make it work if you don’t have a clear budget. So, set your budget and attempt to shortlist the options that are cost-effective and fall in your budget.

How Have We Chosen the Best Taper Jigs?

While shortlisting the products, we have considered different factors to make sure that you get the best products on a single page.

Price

For us, the price of the product was among the most crucial factors because not everyone can spend a lot of money on taper jigs. For this reason, we have tried our best to hunt the products from different price ranges so that you will have something to fit in your budget no matter how much you are willing to spend. You can compare prices and features of different products and choose one accordingly.

Brand

The other important factor that we have considered is the brand and its online reputation. Different sellers use different materials and sell different types of products with varying features. So, you need to understand a product’s key features from different brands and make a comparison to know which will suit your needs.

Customer reviews

Most customers leave genuine feedback depending on their experience with the product. Our researchers go through those feedbacks to analyze which product is of good quality and which is not.

Things To Consider When Buying the Best Taper Jig

Different taper jigs have different construction materials and features that affect their efficiency. Here are some important considerations to buy the best taper jigs.

Dimensions and weight

You can’t overlook the jig’s size, or you’ll end up with one that’s too big or too little for your table saw. Each tapering jig has specified dimensions, which you must ensure will benefit your cuts. You should also consider the tool’s weight in addition to its dimensions. You don’t want to end up with a model that is too difficult to operate. You’ll be set to go once you’ve found the right size and weight of the taper jig. This will make it easier to operate the tool when making angled cuts.

Design

Examine the design of the model you wish to buy to determine which one is most suited to your requirements. You should think about the handle and how it feels in your hand. Another thing to think about is if it’s designed for right-handed or left-handed use. There are models that are designed to work for both left and right-handed people. Moreover, go for ergonomic design products that you can use for a longer period without having pain in your hand.

Function

Before acquiring a taper jig, you should think about its functionality. Any taper jig’s functionality is usually determined by the specifications it carries. The higher the functionality, the more sophisticated the specifications are. We recommend buying a taper jig that is versatile and multi-purpose so your team members can use it as needed.

People Also Asked

Which tapering jig size should you get?

This is a matter of the type of task you're doing. The 24-inch long taper jig, on the other hand, will make working with the jig a breeze. Most taper cuts can be accommodated in this way.

Can your taper jig be capable of making smaller angles?

You should be able to make smaller angles depending on the model that you have. The majority of the taper jigs are able to detect 0 to 15 degrees.

What is the maximum size of the workpiece that you can cut with a taper jig?

The standard length of a taper jig is 24 inches, and it allows the user to cut a board without any hassles. You just need to check the available space and buy a taper jig that can fit in there. Put simply, the large-sized taper jig can easily cut workpieces of any size.

Article Contributors

The Woodsmith Review Team’s product reviews and in-depth guides are here to help you choose the best tools and gear to build great-looking projects confidently. Woodsmith is reader-supported: When you buy through links on our site, we may earn an affiliate commission. Large language models (like Artificial Intelligence) may have been used in the research and creation of the content.

Inquiries regarding specific articles or product testing should be sent to aimperiapt@gmail.com