The Best CNC Router to Carve and Create

- Best CNC Router Overall: MYSWEETY CNC Pro Engraver Machine Shop Now ➔

- Runner Up: SainSmart Genmitsu CNC Router Machine Shop Now ➔

- Honorable Mention: Genmitsu CNC Router Kit Shop Now ➔

- Also Consider: Vevor CNC Router Kit Shop Now ➔

- Also Consider: Bobs CNC Router Kit Shop Now ➔

Our Top Picks for CNC Routers in 2024

Best CNC Router Overall

A surprisingly accurate machine that will be easy to use, easy to put together and fun to work with. Although it does come with a GRBL control board, the MySweety won’t come equipped with software so you’ll need to find an acceptable open source solution or splurge on something pricier.

Pros

- Ideal for beginners

- Also comes with laser engraver

- Solid build

Cons

- Does not come with software

Key Features

Although, like most option in its price range, it’s primarily suited for working with soft materials, it’s safe to say that you would need to spend double or more to get a significant upgrade on the performance that the MySweety provides.

If you’re giving this option serious consideration keep in mind that it’s not only a CNC but it will also suit your laser engraving needs, expanding its functionality and adding another fun toy to your arsenal.

Runner Up

With the SainSmart Genmitsu CNC Router Machine you won’t get any unpleasant surprises with unfitting parts or questionable durability. This router comes almost entirely assembled and will be ready to go within a couple of hours of delivery. Designed with safety and efficiency in mind, it comes with acrylic baffles to block stray wood and motor noise suppression to make your time in the workshop as relaxing as possible.

Pros

- The CNC comes partially pre-assembled which limits initial hassle

- Laser module can be added to the unit

- Designed for quiet operation

Cons

- Even though it is advertised as pre-assembled the unit will still take some time to setup

Key Features

The SainSmart Genmitsu router frame offers stability and safety including several useful features such as hard stops and emergency stop control. Add on the laser upgrade for extra functionality.

Honorable Mention

A great model for the complete beginner that uses flexible hardware and open source software making it an ideal candidate for upgrades. You can use any software that is compatible with Arduino, add hardware or do your own laser upgrade by switching out the spindle.

Pros

- Base height raised 4 cm for improved stability

- Upgraded Power adapter that allows you to get to 20,000 rpm

- Open source software available

Cons

- Will not be suitable for more advanced users

Key Features

The offline control interface is a true blessing that will ensure that your CNC doesn’t crash if your computer does. If you’re expecting run of the mill fragile plastic this affordable router will impress with solidly built components. All in all, this is definitely a great option to consider and if you assemble it correctly you’re likely to get an accurate and stable machine for a great price.

Also Consider

One of the most popular and affordable CNC routers, this machine is built with durable materials and has a generous working area of 300mm X1 80mm X 45mm that you can get set up in no time. The Vevor CNC 3018 will need assembly but the instructions are straightforward and easy to follow.

Pros

- Affordable price

- Simple to assemble

- Working travel of 300mm X1 80mm X 45mm

- Comes with programming software

Cons

- Not suitable for harder material like certain metals

Key Features

Able to handle a diverse range of soft material from wood and plastics to soft aluminum and acrylics. It’s one of the best models to upscale because of the standard build which will allow you to easily add some extra space.

Also Consider

Sporting a 24” x 24” cutting area, Bob’s CNC Evolution is a great CNC router Kit made from quality materials that come together to create a solidly built reliable machine. It will make smooth and precise cuts on all three axes and it will impress with rigidity and lack of vibration or noise.

Pros

- Excellent tool design and engineering

- Great cutting surface for the price range

- Excellent customer service

Cons

- Assembly is time consuming

Key Features

What’s more, the brand has plenty of instructional videos available online that can help get you started as well as guide you through the admittedly time intensive assembly process. However, it’s definitely a worthwhile effort. Bob’s CNC Evolution is a wonderfully designed product that is getting compliments from amateurs and professionals alike, and that is quickly making the rounds as one of the highest quality CNCs you can get in the range.

Buyers Guide: Top CNC Routers in 2021

What To Consider Before Buying a CNC Router

CNC routers can range from hundreds to thousands to tens of thousands of dollars. It’s really not a purchase most business owners take lightly, regarding the category they fit in.

And while there are many advantages to owning a professional-level CNC router, we’re going to be focusing on the more affordable models today. These are the CNC routers that fall in the lowest price range and that is best suited for small businesses and hobbyists who do projects in their spare time. These CNC router machines are excellent for learning the ropes and they can definitely bring returns if properly used and thoroughly mastered.

Work area

One of the most important aspects you should keep in mind when choosing a CNC router is the work area. This will limit the size of the project you are able to do so it’s essential that you choose a CNC router machine that is large enough to accommodate the material you need to work with on a daily basis.

Additionally, consider that a CNC router is a voluminous and sturdy machine so be sure to make an assessment if your workshop can fit it or if you’re better off making some adjustments or expansions before getting one.

Assembly

Assembling a CNC router is no easy task and, depending on the manufacturer, it can take from hours to days. The CNC router machine comes either as a kit or pre-assembled.

The kit will require you to assemble the entire unit from scratch and it will take some experience around a workshop to achieve. Proper assembly is essential to accuracy and performance so taking your time and doing a thorough job is your best bet.

Pre-assembled CNC router units come with most of their parts already together, however, some will still require 30 minutes to a few hours of work before you can press Go and collect $200. However, this process will be far less time-consuming and will require significantly less skill and patience than the kit version.

This video from Cuttin It Close will explain all of the different parts of a CNC router, so you can have a better understanding of your new tool:

Materials

Before deciding on a CNC router make sure to check that the option you’re considering is able to work with the material you need. Most affordable CNC routers will be great for soft materials such as wood, plastic, and maybe aluminum but harder metals will stump them. If you’re looking for something with more power you might want to save up for a more heavy-duty model.

Laser engraver

Many CNC routers come with laser add-ons. This can add a new dimension to your projects as well as functionality to your investment. Check if the CNC router you’re considering has this as an add-on or is flexible enough to allow for a DIY upgrade.

People Also Asked

How much does a CNC Router cost?

Professional CNC routers can be run as high as 10,000 and the lower end professional models might go as low as 5,000. The industrial ones are even more expensive running in the tens of thousands. However, there are alternatives for hobbyists or small business owners that will only run you a few hundred dollars.

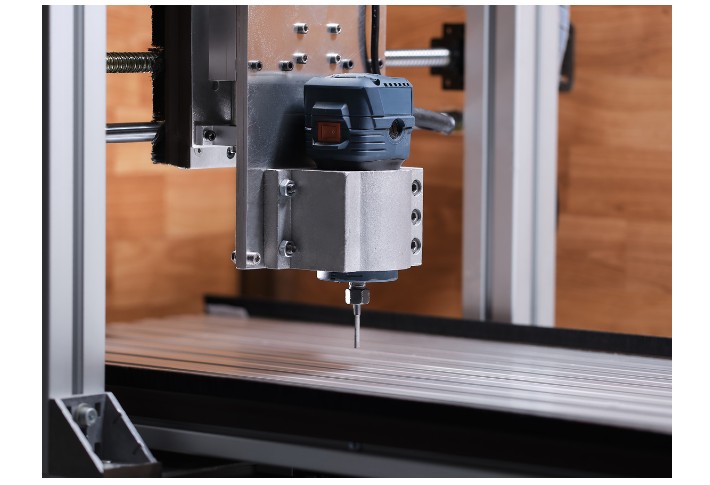

What is the function of a CNC router?

A CNC router or a Computer Numerical Control Router is a cutting machine that is controlled by your computer. It uses a spindle to cut 2D and 3D shapes into various types of material such as wood, metal, plastics or acrylics.

Can you make money with a CNC machine?

It is possible to make money from purchasing a CNC machine. However, it’s important to keep in mind that the CNC router is just a tool and it will not provide a return unless you also put in the work to learn to adequately operate and master it.

What are the disadvantages of a CNC machine?

The two main disadvantages of CNC machines are price and training. Even a starter CNC requires hundreds of dollars of upfront investment. Additionally, making a return or profit usually involves months of learning and mastering the tool and its software.

Article Contributors

The Woodsmith Review Team’s product reviews and in-depth guides are here to help you choose the best tools and gear to build great-looking projects confidently. Woodsmith is reader-supported: When you buy through links on our site, we may earn an affiliate commission. Large language models (like Artificial Intelligence) may have been used in the research and creation of the content.

Inquiries regarding specific articles or product testing should be sent to aimperiapt@gmail.com