How Do You Fix Bubbles in Edge Banding?

The traditional way to hide curved plywood cuts is to edge band them. It is an easy fix and incredibly convenient as the edge band already comes with an adhesive on it. But bubbles can appear underneath the edge banding, where the glue does not properly stick, especially when applying a water-based finish to the wood.

If these bubbles appear in your edge banding, no need to worry. These can easily be removed by employing different fixes, such as using a firm roller, puncturing the hole, or heating it.

Proven Ways To Fix Bubbles in Edge Banding

Here, we have listed three easy methods you can follow to eliminate these bubbles and make your furniture look attractive:

Use a firm roller

This is a simple method that everyone can use! All you need to do is apply pressure to the area where the bubbles have formed in your edge banding by using a firm roller. By exerting pressure, the air will escape from these bubbles, smoothing off your edge banding. Not just that, using a solid roller will also secure the edge banding on your plywood and make sure the glue adheres firmly.

Use heat

For this procedure, you’ll need a clean cloth to press over the bubbling area in your edge banding. Place the cloth on the edge banding and iron the cloth to melt down the hard glue. Apply pressure to the cloth to push the air bubbles down and firmly stick the edge banding to the wood. Make sure you do not iron the same spot for long, or you will burn the cloth and the wood in the process.

Puncture the bubbles

To let the air out of the bubble, carefully make a small hole or incision using a needle or blade. Reheat the glue, then apply it after filling in the small gap as necessary. But be careful — if you accidentally make a big incision, your edge banding will be ruined!

How To Trim Edge Band?

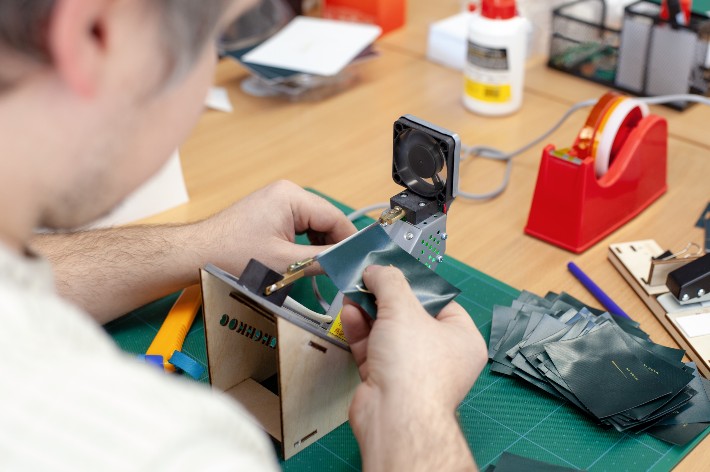

If you want to make the ends of your edge band more presentable, you should acquire an edge banding trimmer. In addition to it being economical, it also makes cutting very simple.

Just push the edge banding trimmer on the panel’s face after your edge banding has cooled down and move it forward so the blade can trim off the extra banding.

Make sure to avoid using the trimmer on two-ply or paper-backed wood veneer since it can damage them. You can also use a skewed chisel to trim your edge band, but it can leave your edge banding with untidy ends, which you will need to sand down later.

Tips To Make Your Edge Banding Neat

Since edge banding can quickly form bubbles and look untidy, here are some tips that will help you edge band your plywood without any mistakes:

- It’s crucial to match the wood of your edge banding with the plywood you’re using. This ensures that the colors match when your design is completed.

- To make it easier to sand and smooth, choose an edge band that is just a little broader than the width of the wood you’re covering.

- Press the edge band firmly when the glue melts to prevent bubbles from forming in the first place.