Best Metal Clamps To Connect Your Crafting

Every metalworking, woodworking, and plumbing job requires the use of a metal clamp. Every cabinet business owner should have this item in their toolbox. Metal clamps are tiny, yet they simplify and organize every project. For example, if you want to connect many boards to create a larger surface, you will need this tool to provide pressure to keep them together. Metal clamps may also be used to glue cabinet edges together and join all sides of a box. Selecting the perfect one, on the other hand, is a difficult task. Metal clamps come in a variety of brands, and while they may all appear to be the same, they are not all created equal in terms of functionality. But don’t feel anxious; we’ve got all the information you’ll need to pick the best metal clamp in 2023.

- Best Overall: Wideskall Spring Clamps Shop Now ➔

- Runner Up: Spring Clamps By Online Best Service Shop Now ➔

- Honorable Mention: Workpro Spring Clamp Set Shop Now ➔

- Also Consider: Irwin Vise Grip Clamps Shop Now ➔

- Tekton C-Clamp Shop Now ➔

Top Metal Clamps on Amazon in 2023

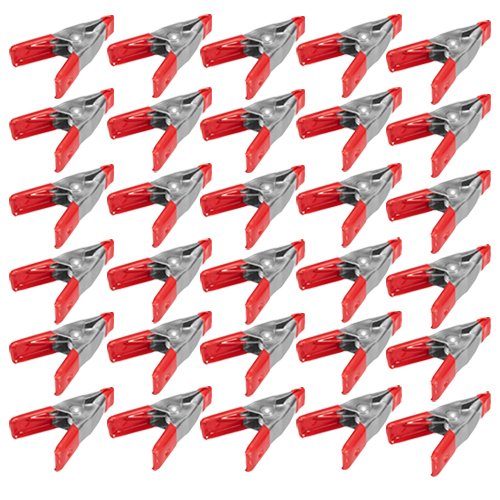

Best Overall

Make sure you have a good supply of these Wideskall Spring Clamps on hand. They are composed of durable materials and are ideal for a variety of purposes. These little spring clamps can be used for a number of projects and activities. They are useful for gluing, photography, and a variety of other tasks. For your convenience, these nylon spring clamps come in a pack of 20 and many additional size packs.

Pros

- Attaching, gripping, and grasping are all possible with little spring clamps

- Ideal for a range of handicrafts and hobbies

Cons

- Does not offer a strong grip

Runner Up

The online finest service’s collection of 4 to 6 inches spring clamps ensures a secure grasp. The materials used to make these clamps are of the highest quality. PVC-coated handles and tips are included, allowing the pinch clamp to create physical strain. So because spring wire material is a bit thinner than another spring clamp, some clamping strength may be absent.

Pros

- Simple to move or slide the clamp points and handles

- The clamp can generate sufficient strain to hold two workpieces securely

- For further sturdiness, the grip and tips are laminated with PVC

Cons

- Since the spring wire is just a little narrower, they don’t have a lot of clamping force

Honorable Mention

WorkPro’s Spring Clamp Set is a lightweight and sturdy tool. They are used for photographic backgrounds, wood, woodworking, arts, and crafts, among other things. The clamps were constructed of reinforced nylon, which made them robust and long-lasting. They are coated with thick cushions to improve their longevity. The red pads can readily rotate up to a forty-five-degree angle while working with unusual items. Furthermore, the tiny textured geometric surface provides superior friction and prevents slippage. As a result, the nylon spring clamp is capable of providing great holding force.

Pros

- Its good textured surface aids gripping by preventing slippage

- To hold random items, the flexible pads may swivel up to forty-five degrees

Cons

- The red pads are readily broken off because they are constructed of a low-cost material

Also Consider

Irwin is a well-known name in the welding business. They are known for offering high-quality welding equipment at a reasonable cost. Because of their flexibility and longevity, they are perhaps the best inexpensive welding clamps available. This C-clamp type clamp is available in a pack of four or separately. The jaw expands to a width of 4 inches, giving you a lot of working options. They also include a trigger release that locks the clamps in place and quickly releases them when you are ready to use them. The broad jaw combined with the locking characteristics is one of the clamp set’s distinguishing qualities. The jaw provides plenty of area for gripping a variety of shapes and sizes, but it does confine you to a single style or form for gripping.

Pros

- With a locking screw and a trigger-release mechanism, it’s simple to set up

- Budget-friendly price without sacrificing quality

- Irwin offers a lifetime warranty on its products

Cons

- If too much force is exerted, the handle may shatter

TEKTON C-Clamps are strong and versatile, securing pieces for assembling, fastening, gluing, and welding. This dependable worker ensures that things stay wherever you leave them, from furniture production and woodworking to welding and automotive industries. This versatile clamp secures components for assembling, fastening, gluing, and welding in woodworking, metalworking, and automotive applications. The rotating jaw pad glides in a low resistance joint to evenly distribute force. The sliding handlebar allows for a variety of hand placements for maximum leverage.

Pros

- The I-beam shape adds strength to the structure, which is composed of cast aluminum alloys

- The Acme-threaded screw is chrome plated and slides easily without binding or sticking

Cons

- Poor workmanship

Best Metal Clamps Buyer’s Guide

Metal Clamps are one of the most commonly used items in the toolkit of a craftsman. Clamps exist in a variety of sizes, kinds, materials, and functions, and a clamp designed for a carpenter may not be suitable for an automobile mechanic. Hence, we will go over some items to think about while purchasing clamps for your projects.

What Are the Different Types of Metal Clamps Available in the Market?

C-Clamps

A C-Clamp, sometimes known as a G-Clamp, is distinguished by its C or G-shaped frame. It is one of the most often utilized clamping tools in a variety of applications. C-clamps are commonly used to secure a wooden or metal workpiece, but they aren’t simply for welding and carpentry. C-clamps come in a range of dimensions, and their strain capacity varies depending on the type. These clamps may be utilized in a variety of industries, including metal, woodworking, automotive, and others.

F-Clamps

An F-Clamp is shaped like an “F,” as the name implies. F-Clamps, sometimes called bar clamps, are identical to C-Clamps but can hold larger workpieces. They are mostly utilized in the woodworking and metalworking industries. F-Clamps are used to hold wooden things in place until they are precisely glued, bolted, or otherwise completed. They perform a similar role in metalworking, except attaching or welding is used instead of gluing or fastening. A slider bar is used in an F-Clamp to give a high opening capacity for working with bigger applications.

Quick grip clamps

As the name implies, quick grip clamps are single-handedly operated and are ideal for tiny workpieces. Quick grip clamps have narrower jaws that can operate with smaller workpieces and in tighter areas. Using a quick-grip clamp is the way to go if you are working with anything smaller. Woodworking and metalworking may both benefit from fast grip clamps.

Bench vice clamps

To keep bigger workpieces together, a bench vice is usually kept and mounted to the workbench. A bench vice is unquestionably the most powerful of the clamps described above. It may be utilized to deal with bigger workpieces while retaining the highest level of accuracy.

What Are the Features To Look For in a Metal Clamp?

Durability

The material that your clamps are constructed of may have a significant impact on their quality and durability. You don’t want to spend money on clamps that will break down the moment you apply pressure on them. Iron is a tough substance that will get the job done, but steel is the ideal option. Steel is the best alternative if you have the choice between iron and steel. Steel may not always be a choice for the sort of clamp that best suits your demands, so be aware that iron will suffice.

Padding features

If you are concerned about clamps leaving bruises, marks, blisters, or scars on your material, you can choose a clamp with some type of cushioning. There are also soft clamps available that won’t scratch your surfaces. The padding might increase the price of the clamp, so keep that in mind while making your purchase. At almost the same time, there is a slew of low-cost alternatives with cushioning and soft-grip characteristics. One thing to keep in mind about the padding characteristics is that the clamp tool may not always have a cushioned grip or end. Some clamps are designed with a “soft grip” function that provides a hard but delicate hold. This means you may tighten the grip without fear of scratches or abrasions caused by the jaws’ substance.

Size

Check the radius of any metal clamp before buying it to see whether it will work for your needs. The diameter of a clamp is usually used to determine its size. If the thing you are clamping is particularly wide, you will need to locate a clamp that can keep it together. Don’t choose the first size you see and be disappointed when it doesn’t keep anything together.

User-friendliness

Every metal clamp comes with some very essential features to ensure that it performs as intended. However, you may need to double-check user-friendly elements that improve user comfort. For example, you will want to search for clamps with a quick-release mechanism and enough room to gently spin the crank handle. Every metal clamp comes with some very essential features to ensure that it performs as intended. However, you may need to double-check user-friendly elements that improve user comfort. For example, you will want to search for clamps with a quick-release mechanism and enough room to gently spin the crank handle.

What Are the Factors To Consider Before Buying a Metal Clamp?

Purpose

First and foremost, decide what purpose clamps will serve. Are you planning on using them for any woodworking, automotive, or DIY projects? F-Clamps and C-Clamps may be a good choice if you need a versatile pair of clamps. These clamps could be used for a variety of tasks, including carpentry and welding. They are also reasonably priced.

Cost

For some of you, the price may be the most essential consideration. Any clamp’s price is determined by its quality, durability, adaptability, material, and a variety of other variables. Clamps, fortunately, aren’t as costly as you would think. Many of the best-selling clamps are available for less than $30. However, depending on your needs, you may go as high as $100.

Material

Any industrial tool’s durability, flexibility, and constructional impacts are determined by the material it is made of. Clamps come in a variety of materials, as previously mentioned. If the clamp has chrome and zinc coating, it indicates that it is durable and will likely last a lifetime. Furthermore, metal or aluminum clamps will keep your clamps from rusting.

What Are Metal Clamps Made Of?

Iron

Cast iron is a typical material for frame construction. It’s a kind of iron high in graphite, silicon, and manganese but low in manganese. The process of converting iron into a liquid condition is referred to as “casting.” Casting implies that the iron has been heated to a liquid state, then poured into a mold and allowed to solidify. Although certain types of iron are brittle, the iron used in the manufacture of clamps is malleable to avoid shattering. Iron is also robust, making it an appropriate material for the frame, which is intended to resist severe labor loads and regular usage as the clamp’s major component.

Steel

Steel, an iron-carbon alloy, is another material that may be utilized for the clamp frame. Because of its excellent tensile strength and corrosion resistance, it is frequently utilized in construction. The steel is generally forged, which is a technique in which the metal is formed by compressive pressures. For forged steel is used, the body will be of excellent performance and durability, which is advantageous when holding a large or heavy workpiece.

If you are a DIYer, check the video from Kwando Technic to learn ways to make a long reach clamp with fast clamping function.

PEOPLE ALSO ASKED

How can I keep my metal clamp in good condition?

Metal clamps are easy to maintain. After each procedure, be careful to wipe it out. Allowing dirt to settle on it will result in discolored workpieces. Also, keep the clamp dry and apply oil to its working components on a regular basis. You’ll prevent rusting your metal clamp this way.

What is a clamp’s function?

A clamp is a fastening mechanism that uses inward pressure to hold or secure items securely together to prevent movement or separation.

What are the consequences of incorrect clamping?

Inadequate clamping force causes the workpiece to slide and shake during processing, resulting in machining errors and perhaps damaging the workpiece and cutting tool.

Article Contributors

The Woodsmith Review Team’s product reviews and in-depth guides are here to help you choose the best tools and gear to build great-looking projects confidently. Woodsmith is reader-supported: When you buy through links on our site, we may earn an affiliate commission. Large language models (like Artificial Intelligence) may have been used in the research and creation of the content.

Inquiries regarding specific articles or product testing should be sent to aimperiapt@gmail.com