Bridle joints are perfect for large and tall cabinet doors like those on the tool cabinet. (This joinery is also used on doors with glass panels.) The large glue surface of bridle joints make it the ideal joint to use on doors where a strong, rigid frame is required.

The joint consists of an open mortise (in the stile) and a tenon (in the rail). You could do the tenons with your miter gauge and a dado blade installed in your table saw. But since I needed to make the jig for the stiles, I decided to use it for both workpieces.

Bridle joints are perfect for large and tall cabinet doors like those on the tool cabinet. (This joinery is also used on doors with glass panels.) The large glue surface of bridle joints make it the ideal joint to use on doors where a strong, rigid frame is required.

The joint consists of an open mortise (in the stile) and a tenon (in the rail). You could do the tenons with your miter gauge and a dado blade installed in your table saw. But since I needed to make the jig for the stiles, I decided to use it for both workpieces.

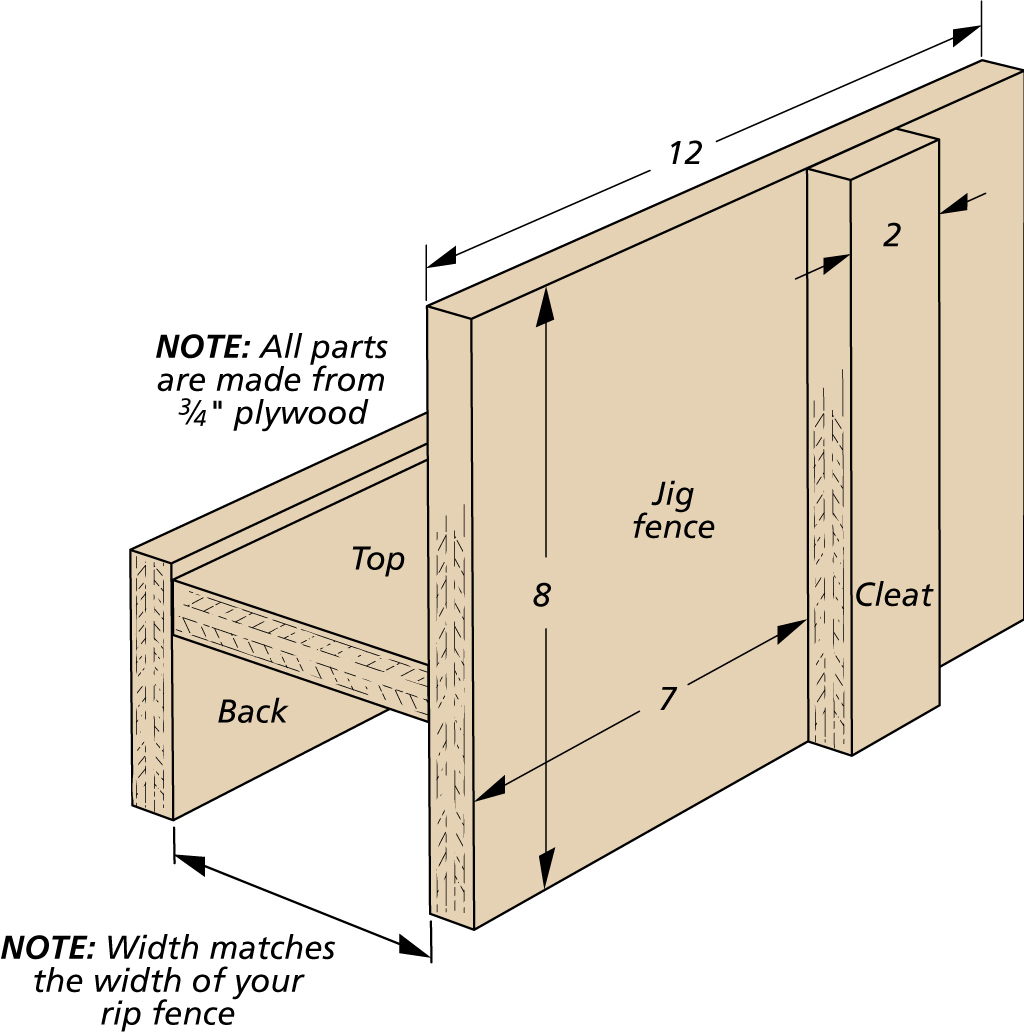

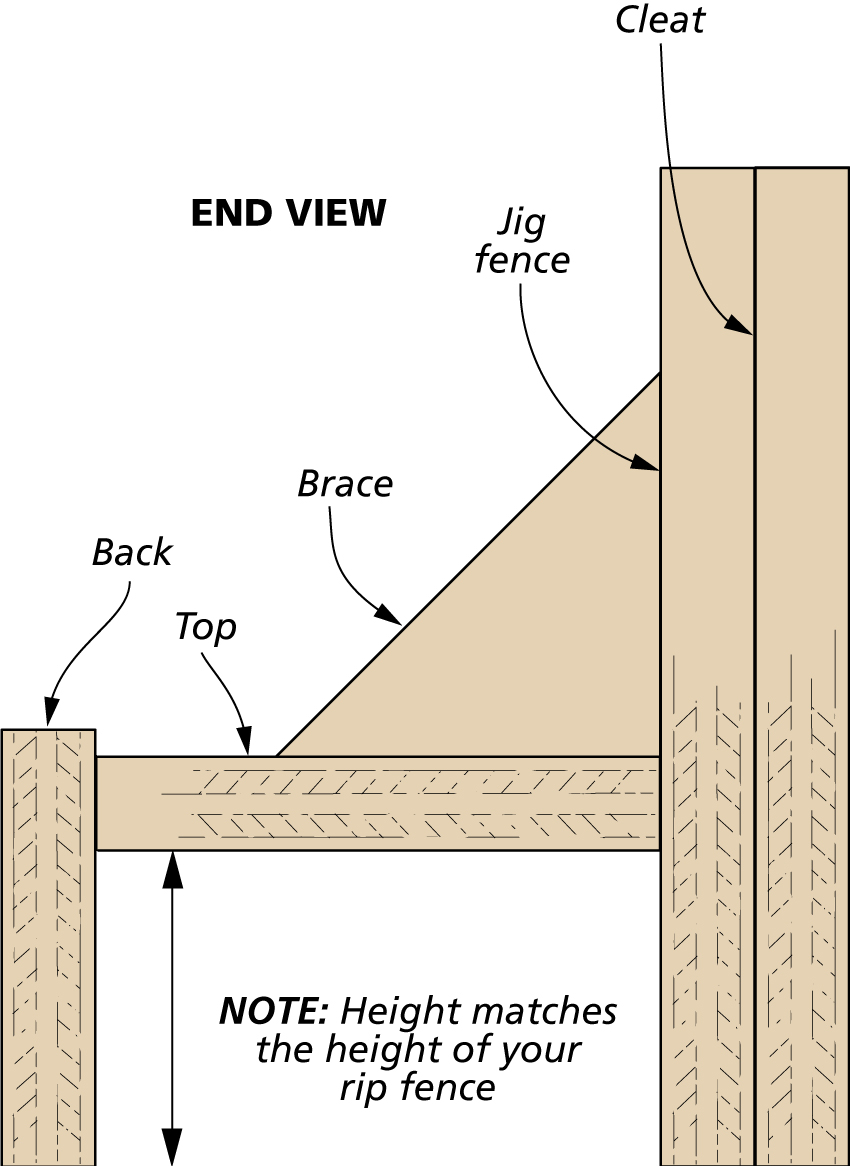

As you see in the drawings above, the jig straddles the rip fence of your table saw. The fence and cleat should be tall enough to let you clamp the workpieces to the fence of the jig.

As you see in the drawings above, the jig straddles the rip fence of your table saw. The fence and cleat should be tall enough to let you clamp the workpieces to the fence of the jig.

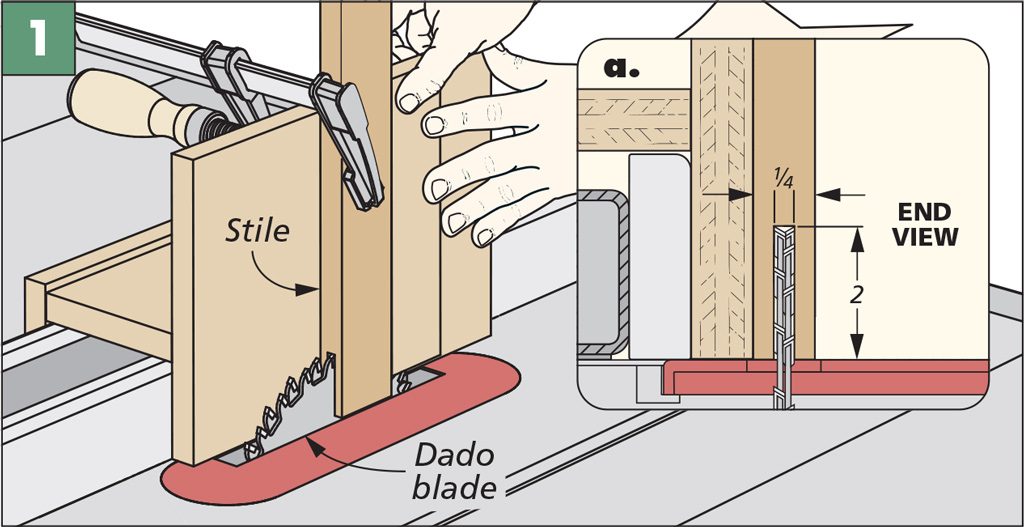

I started with the mortises in the stiles (Figure 1). The cleat holds the stile square and acts as a backer that prevents chipout.

I started with the mortises in the stiles (Figure 1). The cleat holds the stile square and acts as a backer that prevents chipout.

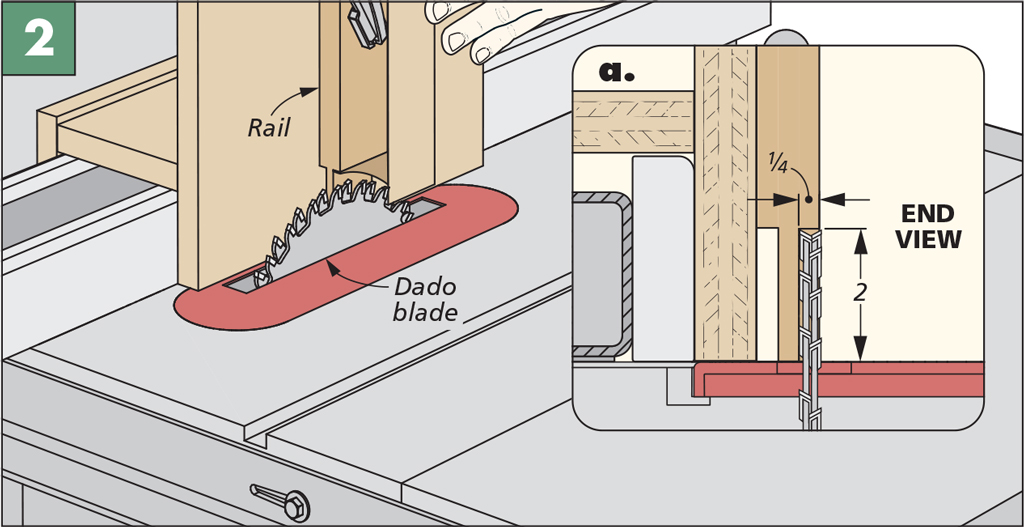

Figure 2 shows cutting the tenon on the end of the rail. It’s just a matter of adjusting the distance of the rip fence to make the centered tenon.

Figure 2 shows cutting the tenon on the end of the rail. It’s just a matter of adjusting the distance of the rip fence to make the centered tenon.

Subscribe Today